-

Agglomeration | Iron Steel | Kuettner Group

Therefore, various agglomeration processes are used to deliver such finer raw materials to the blast furnace. Küttner is involved in these processes at various points. Sintering The most common agglomeration process is the sintering of fine ore. As a rule, larger amounts of circulation material are used in the sintering plant.

Get Price -

Agglomeration During The Process Of Iron Ore Pelletizing

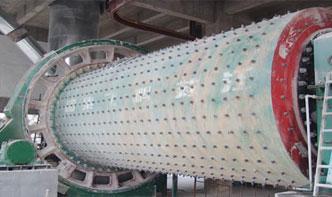

Iron ore pelletizing or balling is the process of transforming fines into spherical granules anywhere from 8 – 16mm in size via tumblegrowth agitation agglomeration using either a disc pelletizer pan granulator or rotary drum. Agglomeration of Iron Ores 1st Edition Ram Pravesh

Get Price -

agglomeration of iron ore fines process

Know More ; A Detailed Look at Iron Ore Agglomeration Know More A Detailed Look at Iron Ore Agglomeration A Detailed Look at Iron Ore Agglomeration, To eliminate dust issues associated with iron ore fin, as well as a continuous process loop to create the ideal iron ore agglomeration process Items such as attrition, crush strength, compression, and bulk .

Get Price -

Sintering and Pelletizing

Ensure your plant's high performance and profitability while lowering investment and operating costs with our agglomeration technologies. Our innovative sintering and pelletizing solutions are based on over 60 years' experience and worldclass RD. Outotec Traveling Grate Sintering is suitable for sintering a wide range of raw materials, including iron, manganese, .

Get Price -

agglomeration of iron ore fines process belt conveyors for sand

Iron Ore Agglomeration Processes and their Historical Development There are four type. Call Us: +86 371 . Email: [email protected] Home; Product ... Fig 1 Agglomeration processes Briquetting is the simplest and earliest applied Of Iron Ore Fines Process,Agglomeration Of Iron Ore Fines .

Get Price -

HYFOR – HYdrogenbased FineOre Reduction

lower (iron content and grain size), while huge amounts of fines (concentrates) are available. The HYFORprocess is the only process which allows using iron ore concentrates with particle sizes of <150 µm, typical for various iron ore concentrates, directly without prior agglomeration. Any type of iron ore ( hematite, limonite ...

Get Price -

agglomeration of iron ore fines process

Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade Iron Ore Tsutomu NOMURA *1, Norihito YAMAMOTO *2, Takeshi FUJII, Yuta TAKIGUCHI *3 *1 Technology Process Engineering Dept., Iron Unit Div., Engineering Business

Get Price -

Agglomeration of Ferroalloy Fines for use in Bulk Steelmaking Process.

· Therefore, we at Tata Steel developed an agglomeration process for ferroalloy fines and used the briquettes ... like FeMn, SiMn, FeSi and FeCr manufactured by carbothermic reduction of ores in submerged arc furnaces ... Proc. of the 69th Steelmaking Conf., 69(1986), 315. [3] Y. Lee, H Berg, B. Jensen, and J. Sandberg: Iron and ...

Get Price -

Agglomeration of titanium ores containing iron

in the production of agglomerated ironcontaining titanium ores suitable for reduction of the iron contained therein, wherein finely divided ore particles are wetted, shaped into large molded agglomerates, dried and hardened, the improvement which comprises admixing with said ore particles prior to hardening about to 30% by weight of the ore of a compound of iron, .

Get Price -

what is agglomeration of ore

Heap leaching is an industrial mining process to extract precious metals, copper, uranium, and, Similar to in situ mining, heap leach mining differs in that it places ore on a liner, then, In recent years, the addition of an agglomeration drum has improved on the heap leaching process by allowing for a more efficient leach...

Get Price -

Briquetting of Iron Bearing Materials

lumpy forms are called agglomerates and the process is called agglomeration. There are three main types of agglomeration process: Pelletization, sintering and briquetting. Pelletization: It is one of the agglomeration processes. A mixture of iron ore fines, binder and moisture is taken

Get Price -

agglomeration of iron ore fines process

· Iron Ore Agglomeration Technologies IntechOpen. Sintering is a thermal process (1300–1400°C) by which a mixture of iron ore, return fines, recycled products of the iron and steel industry (mill scale, blast furnace dusts, etc.), slagforming elements, fluxes and coke are agglomerated in a sinter plant with the purpose of manufacturing a sintered .

Get Price -

agglomeration of iron ore fines process

Iron Ore Agglomeration Processes and their Historical . Dec 28, 2015 Fig 1 Agglomeration processes. Briquetting is the simplest and earliest applied process. Fine grained iron ores are pressed in to pillow shaped briquettes with the addition of some water or some other binder under high mechanical compressive pressure.

Get Price -

Iron ore pricing explained

· In general, higher purity ores help increase hot metal yields in the blast furnace, and also lower production cost by reducing the amount of coke required. For these reasons, the rule of thumb is "higher Fe grade, higher price.". Iron ore also differs in physical form. Fines require sintering (agglomeration into crude pellets) prior to use ...

Get Price -

Composite Agglomeration Process of Iron Fines

Composite Agglomeration Process of Iron Fines. Tao Jiang, School of Minerals Processing and Bioengineering, Central South University, Changsha, Hunan 410083, ... Comprehensive Comparison of CAP with Other Agglomeration Processes. Conclusions. Acknowledgments. Citing Literature. 3rd International Symposium on High‐Temperature Metallurgical ...

Get Price -

iron ore agglomeration process supplier for malayisa

Primetals Technologies develops breakthrough, 2019/06/26 0183 32 Only process worldwide directly using iron ore concentrate fines from ore beneficiation with particle sizes of 100 smaller than 015 mm Low CO2 footprint due to usage of H2 as reduction agent Lower Opex and Capex Cost due to no agglomeration,...

Get Price -

Heap Leaching Agglomeration

· During agglomeration, the clay and fine particles contained in the ore adhere to the coarser particles and create a coating of fines around the coarse particles. The agglomerates produced are of sufficient green strength after curing to .

Get Price -

Agglomeration of Iron Ores

This book focuses on agglomeration, or the size enlargement process, of iron ores. This process sits at the interface of mineral processing and extractive metallurgy. The book begins with a discussion of raw materials preparation and the beneficiation process. It then describes fundamental principles of the sintering and pelletization processes, including formation of .

Get Price -

agglomeration | metallurgy | Britannica

In iron processing: Crushing Fines, however, must first be agglomerated, which means reforming them into lumps of suitable size by a process called sintering. Read More Home Science Earth Science, Geologic Time Fossils Earth Sciences lithosphere geology By The Editors of Encyclopaedia Britannica • Edit History Key People: Marcia McNutt

Get Price