-

BURNER TECHNOLOGY Krasnoyarsk's burner exchange

It consists of three kilns with a combined capacity of 662,000tpa. The wetprocess Kiln Line 5 is φ4 x 150m with a clinker capacity of 804tpd. Until 2018 thermal energy was supplied by a directfired ball mill burner system. The replacement of this burner system was imminent due to more rigorous emission regulations, particularly NO x

Get Price -

Classifiion of the Rotary KilnRotary kiln,rotary dryer_Hongke .

3. According to the energy supply effect: gas, coal, mixed fuel kiln. Fourth, according to the feeding method: According to whether the material entering the kiln carries water, it can be divided into dry and wet rotary kilns. Wet kiln can be divided into inflow method and injection method. In addition to the dry method kiln, there is also a ...

Get Price -

Ball Mill Design For Coal Firing Kiln In India

ball mill design for coal firing kiln ball mill design for coal firing kiln in india. ball mill for coal grinding in India is the most commonly used Mineral processing equipment, ball mill for coal grinding in India used in many parts of the world, selling in more than 30 countries and regions, and to be recognized. Read more . Coal Firing System .

Get Price -

Coal Mill – Coal Mill In Cement Plant | AGICO Cement Equipment

The coal mill grinding system is an important part of the dry process cement manufacturing. In cement plants, we usually adopt the air swept coal mill system or vertical mill system as the pulverized coal preparation system, which is arranged at the cement kiln head or kiln tail to provide fuel for clinker calcination. However, due to the flammable and explosive .

Get Price -

Coal Mill Bhel Drawing 250mw

China Thermal Coal, China Thermal Coal Manufacturers, China .. Thermal Oil Hater drawing can be provided are .. Thermal Power Plant 25MW – 250MW Engineering Design to .. AirSwept coal mill (+) Min. Order: 1 Set FOB ..

Get Price -

ball mill coal reject chute

ball mill coal reject chute Mobile Crushers all over the . ball mill coal reject chute heavy industry is specialized in the design manufacture and supply of crushing equipment used in mining industry. ball mill gold reject chute utilysation of coal mill reject ball mill coal reject chuteesicsronagpurin.

Get Price -

Kiln Firing

Three factors made it possible: 1) The low firing temperature. 2) Even slower firing speed (24 hours instead of 12 hours to ramp). 3) Elimination of the direct radiant heat. This clever potter fires using only the elements in the bottom one/third of the kiln (the top 2/3 elements never go on) and puts the rings only in the top 2/3 of the kiln.

Get Price -

kiln design calculation

Jul 22, 2010· Degree Of Kiln filling Kiln Cross Sectional loading: % of Filling or Area of this segment (A1) = Kilns Degree Area of cross section of Kiln (A) Theta Centric Angle Theta % of Kiln (Degree) filling 110 105 100 Segment 95 r = radius inside lining 90 85 r^2 A1 = O – Sin O 80 2 75 70 A = II r^2

Get Price -

100 TPD Sponge Iron Plant Kiln Cooler Spare Part

We manufacturer durable and long life kiln rollers, high quality refractory insulates materials we prepared in a special kiln wall structure to protect for the excellent insulation effect, surface heat outside kiln is below 60 degrees for low fuel consumption. Material : IS 2708 Grade II/ EN19 Forged, EN24 Forged as per client requirement

Get Price -

Christian Pfeiffer product overview · Christian Pfeiffer

We design and build grinding plants and equip them with all the right features or auxiliaries. Our separators ensure even greater efficiency of your processes. And from the first idea to the last screw, we also design and build entire EP or EPCprojects. Mills. Ball mills BAM. Learn more. Christian Pfeiffer VEM Vertical mill. Vertical mill VEM. Learn more. ROP Rollerpress. Learn .

Get Price -

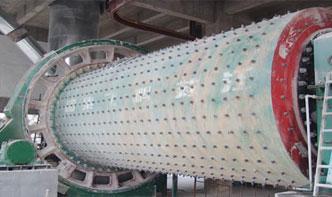

Ball Mills

· CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume.

Get Price -

Coal Mills in Thermal Power Plant | PDF | Mill (Grinding)

Low 10 to 20 RPM Ball tube mills (16 rpm in Vindhyachal) Medium High 40 to 70 RPM 900 to 1000 RPM Bowl Mill, MPS Impact or Mill, Ball and Hammer Race mill Mill. Beater Mill or Fan Mill. TYPES OF MILL Tube or ball mills: These are lowspeed machines that grind. the coal with steel balls in a rotating horizontal cylinder. If the

Get Price -

a project report on coal mill for kiln firing

coal mill safety temperatures Coal Mill,Coal Powder Kiln,Coal ... nepal coal mill safety temperatures Fire and Explosion Prevention in ... hydraulic cylinder project report coal mill ... Chat Now; coal crusher and mill design projects automatic mini coal mill plant project report ... Coal Crusher and Coal Mills ... rotary kiln, clinker cooler ...

Get Price -

ceramic ball millRotary kiln,rotary dryer_Hongke Heavy .

Ceramic ball mill is chiefly used for the mixing and grinding of materials, which can be used in not only dry grinding but also wet grinding. The fineness of the final products is uniform with power saving. The ball mill can adopt different lining board types to satisfy different needs of the customers according to the production.

Get Price -

ball mill design for coal firing kiln in india

ball mill design for coal firing kiln . coal mill manufacturer, coal pulverizer, coal grinding mill has been concerned with coal pulverized fuel for kiln and boiler firing for many years can manufacture and supply coal mill of different types which includes ball mill, MTW trapezium mill, MTMTake vertical coal mill for example, the coal mill is a modular and flexible design . .

Get Price -

Coal Fuel Rotary Kiln with Various Output and Length for Sale

Coal fuel rotary kiln or coalfired rotary kiln is a kind of rotary kiln equipment that uses coal as fuel. The fuel types of rotary kiln include gas ( gasfired rotary kiln ), liquid ( oilfired rotary kiln ), and solid or powder. Because coal is the cheapest fuel compared with other fuels, coalfired rotary kiln is widely used in the world.

Get Price -

Vertical Coal Mill Inlet Negative Pressure

after many times of renovating design mtz steel ball coal mill fully adopts the doubleinlet double outlet coal mill technology the product is widely used for coal pulveriing system pulveried coal preparation in the industries of power metallurgy building material chemical and environment protection etc especially applicable for the bituminous .

Get Price -

tirax coal mill internal design

· Coal Ball Mill Electrics are for 50Hz Used 300 tpd White Cement Plant, FL Kilns and Mills, 60Hz ... • Internal type shell flanges ... X 6m FLS Tirax Coal Mill, 165kW 50Hz. Please inquire. X FCB Coal Ball Mill, 3 tph, 160kW 50Hz. Get price roller and ball coal mill at khaparkheda

Get Price -

DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR ROLLER PRESS .

Ball mills (Fig ) are coming in cement plant areas of raw grinding, coal grinding and cement grinding which in turn as raw mill, coal mill and cement mill. Ball mills are horizontal tube mills having single or two compartments for grinding, Balls as grinding media and driven by side or .

Get Price -

kiln operator cement plant

may 14, 2015· cemex, inc., cemex, the owner and operator of a portland cement manufacturing facility in lyons, colorado, agreed to operate advanced pollution controls on its kiln and pay a 1 million civil penalty to resolve alleged violations that it was releasing pollutants to the air, including nox, so2 and carbon monoxide, without required .

Get Price