-

FAG Rolling Bearings in Rolling Mills

angular contact ball bearings or deep groove ball bearings. In backup rolls for large fourhigh strip mills and foil mills, a deep groove ball bearing is often sufficient as an axial bearing, Figure 9. It generally has the same section height as the radial cylindrical roller bearing to which it is assigned. In place of the deep groove ball

Get Price -

Choosing the Best Media Mill For Your Wet Grinding Appliion

· Figure 3 depicts the effects of media size on grinding times. From this plot, it is shown that a target fineness of 80% < 2 microns is normally achieved in 315 minutes of recirculation milling with to mm grinding media. By reducing the media diameter to to mm after 90 minutes, the target grind is achieved in only 150 minutes.

Get Price -

Six factors affecting the output of grinding mill | DC Velocity

· In short, we can learn more easily to improve the output of the mill after understanding the influencing factors. 1. Particle size of finished product. The fineness of the material after grinding by the mill requires high fineness, that is, the finer the material is, the smaller the milling capacity of the grinding mill is. If customers have ...

Get Price -

A New Milling 101: Milling Forces and Formulas

· Radial forces tend to push away the tool and account for 10 percent of the cutting forces. The tool's rake controls the degree of cutting forces and power consumption, the strength of the cutting edge, and the direction of chip flow. As a rake angle becomes more negative, cutting forces increase and edge strength improves.

Get Price -

EFFECT OF GRINDING MEDIA ON THE MILLING EFFICIENCY OF A BALL MILL .

Sažetak. The size of grinding media is the primary factor that affects the overall milling efficiency of a ball mill ( power consumption and particle size breakage). This article tackles the lack of a design tool that could help choose the ball loading composition in mills. Such a tool enables the maximization of the exposed surface area ...

Get Price -

AMIT 145: Lesson 3 Dense Medium Separation – Mining Mill .

Density of Water = 1000 kg/m 3; 1 m 3 of Water = 1000 kg. Magnetite Density = 5170 kg/m 3. [image 145329] [image 145330] For example, a 400 tph feed to a dense medium process equates to a volumetric flow rate of 1000 gallons/min or m 3 /min. At a 4:1 mediumtocoal ratio, the volume of medium is m 3 /min.

Get Price -

Top 5 productspecific milling technologies used in industrial ...

· A closedloop ball mill/classifier circuit can be positioned on load cells for weighing the total mill content of media and material. Incorporation of load cells represents the latest technology for controlling the feed rate to the ball mill. By controlling the mill weight, the optimal amount of material is always in the mill bed and the milling efficiency is optimized by never .

Get Price -

STARTLING EFFECT OF BALL SCATS REMOVAL ON SAG MILL .

An increase of over 10% in mill throughput was achieved by removing the ball ss from a singlestage SAG mill. These ss are non spherical ball fragments resulting from uneven wear of balls...

Get Price -

Rolling Process: Definition, Working, Appliion, Defects, Type of ...

2. ThreeHigh Rolling Mills: In this mill, the three rolls stand in parallel one by others. The rolls are rotating in opposite directions. In this mill, between the first and the second rolls, the material passes. If the second roll rotates in a direction then the bottom roll rotates in another direction.

Get Price -

ball mill 425 300 micro

Ball End Mills End Mills Grainger Industrial Supply. Ball end mills have a rounded nose and create a round bottomed groove in milling tasks Also known as ball nose end mills they are rotated against a workpiece to make round bottomed slots and pockets or mill complex shapes without sharp corners Each end mill has flutes on its cutting head that carry chips away from .

Get Price -

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS

Effect of ball size 29 Empirical approaches 29 Probabilistic approaches 33 Abnormal breakage 36 Effect of ball mixture 37 Ball size distribution in tumbling mills 37 Milling performance of a ball size distribution 40 Summary 41 Chapter 3 Experimental equipment and programme 43

Get Price -

Six factors affecting the output of grinding mill | DC Velocity

· The type of the mill also affects the output of the mill. If it is a common Raymond mill, the output will be very general. If it is a pressurized Raymond mill, the output of the mill will be greatly improved. Compared with other Raymond mills, the roller mill can increase the output by 10% ~ 30% under the condition of equal power and equal ...

Get Price -

The influence of the production method of the Grinding Media Balls .

Jiangyin Dongbang Steel Ball Machinery Co.,Ltd. ADD: Hua Lu Road, Huashi Town, Jiangyin City, Jiangsu Province. Tel:. Mobile:

Get Price -

The effect of ball milling on the ph of Mgbased metals, oxides .

· The pH variation induced electrochemical reactions for Zn, Mg, MgO and the mixture MgMgO (25 wt.% Mg and 75 wt.% MgO) fabried by highenergy mechanical ball milling in wt.% NaCl have been investigated using the potentiodynamic method and electrochemical impedance spectroscopy to control the rate of magnesium dissolution as hodic protection. It .

Get Price -

ball mill effect of amount of media

Ball Mill Effect Of Amount Of Media high impact toughness forged grinding media balls for ball · for the ball mills, while the power draw determined by DEM simulation impact the particle, and the mill shell, grinding media, particle and lifter are but higher speeds result in the wearing of lifters and increased energy ...

Get Price -

ball mill effect of amount of media

· Ball mill— OPERARIONAL PRINCIPLE OF BALL MILL. Generally speaking ceramics factories adopt intermittent ball the inner tube of ball mill loaded are some alumina balls,materials to be grinded and a proper amount of water which are properly matched according to process the inner tude turns around under the effect of motor,the grinding media .

Get Price -

TECHNICAL NOTES 8 GRINDING R. P. King

Figure The effect of mill speed on the power drawn by a rotating mill. The liner profile and the stickiness of the pulp in the mill can have a significant effect on the actual critical velocity. Mills usually operate in the range 65 82% of critical but values as high as 90% are sometimes used. A crucial parameter that defines the performance of a mill is the energy consumption. .

Get Price -

Production of CWM with wet type ball mill (part 3). Influence of .

Made available by Department of Energy Office of Scientific and Technical Information ...

Get Price -

effect of ball mill grinding process

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING . Effect of ball mixture 37 Ball size distribution in tumbling mills 37 Milling performance of a ball size distribution 40 Summary 41 Chapter 3 Experimental equipment and programme 43 Laboratory grinding mill configuration 43 Preparation of monosize grinding media 44 ...

Get Price -

How To Choose a Stepover for 3D Profiling

To put real numbers on this, that would be equavalent to a .012, .025, and .042″ stepover for a .125″ ball mill. Stepover =1/10 of diameter Stepover =1/5 of diameter Stepover =1/3 of diameter As you can see, the change in quality is so dramatic that you might be tempted to always use the smallest stepover possible. Speed vs Quality

Get Price -

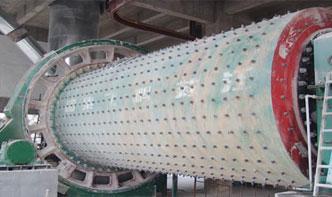

Ball Milling method for synthesis of nanomaterials

1. As the name suggests, the ball milling method consists of balls and a mill chamber. Therefore over all a ball mill contains a stainless steel container and many small iron, hardened steel, silicon carbide, or tungsten carbide balls are made to rotate inside a mill (drum). 2. The powder of a material is taken inside the steel container.

Get Price -

Ball Milling

Reference Lance Frazer, Environmental health perspectives, 2003, 111, 10 Belen Rodríguez, Adv. 2007, 349, 2213 Ana Lazuen Garay, Chem. Soc. Rev., 2007 ...

Get Price -

basic dimensioning ball mill

Industrial Ball Mills Price Buy Cheap Industrial Ball. Steel Ball Mill MODEL 18 x 24 Steel Ball Mill 18 diameter x 24 inside dimensions steel lined with lifter bars inside motor with gear box approximately 60 rpm with no media or material load grinding cover nice basic ball mill STOCK NUMBER DPM2429 Share this product listing Feb 13 2017 The apparent difference in .

Get Price -

Ball Nose Milling Strategy Guide

· Ball Nose Milling Without a Tilt Angle. Ball nose end mills are ideal for machining 3dimensional contour shapes typically found in the mold and die industry, the manufacturing of turbine blades, and fulfilling general part radius properly employ a ball nose end mill (with no tilt angle) and gain the optimal tool life and part finish, follow the 2step process .

Get Price -

Wet Milling Process | Custom Milling Consulting LLC

We will help you choose the most appropriate wet milling process and/or equipment to achieve your desired results. If you are interested in testing different methods, we can use our inhouse toll milling services to help you test our equipment by producing production size batches. Contact us today at for more information.

Get Price