-

Ball Mill And Air Classifier Production System

Product Feature. 01. With Al2O3 or silex or steel designed with overflow type or grate discharge wall. 02. With air through the mill or with airswept principle to get cooler and take out ground material. 03. Inlet chute for ball mill includes accessory for feeding grinding aid directly into the mill drum. 04.

Get Price -

grinding machines manufacturers, largest grinding mill liners

grinding machines manufacturers, largest grinding mill liners SKY Welcome to SKY Founded in 1987, SKY has attained 124 patents on mills over the past 30 years. More than 30 overseas offices not only manifest our popularity, but also solve your puzzles quickly in operation.

Get Price -

Ball mill,Ball mills,Ball grinding mill,Ball grinder,Ball mill machine ...

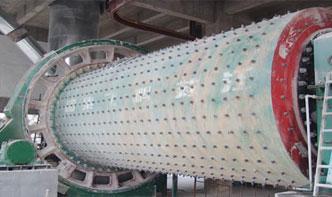

The ball mill is one of the most widely used super fine grinding machine in the industry and it is the key grinding equipment after materials have been crushed. Ball grinding mill is widely used in cement, silie, new construction material, refractory, chemical fertilizer, ferrous metal and nonferrous metal as well as ceramics.

Get Price -

Calculate and Select Ball Mill Ball Size for Optimum Grinding

02/08/2013 · In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case".

Get Price -

ball mill, ball grinding mill, ball mill machine

Ball Mill. Max feeding size: 25 mm. Weight: 5300 t. Power: 151600 kw. Capacity: 1100 tph. Product description: Ball mill machine is parimary used for fine grinding. It is the key equipment for recrushing the materials. Materials out of crusher need to go into Ball Mill for further grinding. It is widely used.

Get Price -

Ball Mill Machine manufacturers suppliers

China Professional Mining Ore Gold Copper Lead Manganese Iron Slag Sliver Aluminum Limestone Gypsum Powder Grinding Wet and Dry Ball Mill Machine. US / Set. (FOB Price)

Get Price -

Batch Ball MillBall millCLIRIK ultrafine grinding millindustrial ...

Batch ball mill is also called ceramic ball mill, with drying work and wet working by batch. It is used for fine grinding of feldspar, quartz, clay, ore, etc. Batch ball mill (ceramic ball mill) is mainly used for mixing, milling of the works with less energy but produces high fineness product.

Get Price -

Planetary Ball Mill PM 100

The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easytouse counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 ml sample material per batch. The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization energy and therefore short ...

Get Price -

Limestone Ball Mill Milling Grinder Machine Dry / wet ball mill

Limestone Ball Mill Milling Grinder Machine Dry / wet ball mill, US 3800 3800 / Ton, Shandong, JHMC, MG350/ from Jinan Heavy Machinery JointStock Co., Ltd. on

Get Price -

Ball Mill Grinding Production LineHenan Engineering ...

The ball mills that can provide include: rod mills, cement mill, r aw material mill, ceramic ball mills, energysaving ball mills, etc. We can provide complete ball mill production line equipment. Ball mill is the key equipment for crushing the material after crushing, the capacity: /H, 50650T/H,etc. the discharge scope(mm):,etc.

Get Price -

Difference and Choice of 2 Common Mills, Ball Mill and Grinding Mill

26/10/2019 · Ball mills are different. The grinding media is unfixed steel ball, etc., which produces larger sized powder than grinding mill. the size of the discharged product can mainly be adjusted between 40250 mesh. If the size of discharged product is uneven, it is needed to equip a powder separating machine.

Get Price -

Ball Mill Machine

Ball Mill Machine China Manufacturers, Suppliers, Factory We offer great strength in quality and development,merchandising,sales and marketing and operation for Ball Mill Machine, Классификатор, Universal Grinding Mill, Coarse Powder Classifier, Silica Sand Ball Mill .

Get Price -

Ball Mills Or Vertical Roller Mills: Which Is Better For Cement Grinding?

Ball mills are factory made and transported to the plant site of the buyer while VRM is built on the site of the cement plant. This helps to reduce cost and complied logistics issues. The equipment cost is, however, higher for a VRM than a ball mill. So these are the pros and cons of the two technologies and a cement manufacturing company ...

Get Price -

Materials Mixing and Grinding Planetary Ball Mill Machine

TMAXXQM series of variable frequency planetary ball mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder.

Get Price -

Grinder, Ball Mill, Ball Mill Machine, Grinding Mill

The grinding media of ball mill machine is steel ball. Good crushing effect, big size reduction ratio, easy to adjust the finished fineness, meet production needs. Easy and safe manipulation, steady running. Strong adaptability, adapting to all kinds of ore materials. Continuous production with big production capacity, meet the demand of modern ...

Get Price -

ball mill, ball grinding mill, ball mill machine

Ball mill machine is parimary used for fine grinding. It is the key equipment for recrushing the materials. Materials out of crusher need to go into Ball Mill for further grinding. It is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silie product, new building material, refractory, fertilizer, black and nonferrous metals and gl

Get Price -

3 Types of Grinding Media for Ball Mills

04/12/2019 · Spherical ball mill media have an advantage of better crushing effect when impacting large particles because point contact between balls and raw materials makes the materials easy to be smashed. Types. Characteristics. Steel. High impact toughness. Spherical. Better crushing effect. steel balls.

Get Price -

Ball Mill, Grinding Mills, Ball Grinding Mill, Ball Mill Grinder ...

Overview . Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silie product, new building material, refractory, fertilizer, black and nonferrous metals and glass ceramic industry.

Get Price -

Others Ball Mill Grinding Machinery

Others Ball Mill Grinding Machinery Total 370 Others Ball Mill Grinding Machinery Products Gallery View . List View . Slide Show 1 / 16. Mining Separating Line Manganese Ore Grinding Mill FOB Price: US 8,50050,000 / set. Min. Order: 1 set . Contact Now. Video. Mining Equipment Ball Mill Grinder for Copper Ore ...

Get Price -

Ball MillGrinding MachineHenan Daiwo Machinery Co.,Ltd

Performance Of Ball Mill: 1. The new ball milling machine can save power of motor of 3040%, lubriing oil 70%, cooling water 90%, and the comprehensive saved energy is over 40%. 2. The headstock of the ball milling machine does not need to change, which saves much maintenance costs and both time and labor. 3.

Get Price -

Grinding Mill, Ball Mill | Heavy Industry

The Grinding Mill of Group can process the nonmetallic material into a coarse powder, middlefine powder,ultrafine powder, and so on many kinds of meshes. Ball Mill. + more. Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many kinds of mine and other materials, or to select ...

Get Price -

Mining Grinding 25r/Min Horizontal Ball Mill Machine For Mine

A grinding ball mill machine consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either horizontal or at a small angle to the horizontal. it is partially filled with balls. The grinding media is the balls, which may be made of steel (chrome steel), stainless steel or rubber. ...

Get Price -

Ball Mill,Ball Mills,Ball Mill Machine,Ball Grinding Mill

Ball Mill machine grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground. The rotation is usually between 4 to 20 revolutions per minute, depending upon the diameter of the ball mill machine. The larger the diameter is, the slower the rotation is.

Get Price -

Manufacturer of Ball Mills and Crusher Machines

Ball Mill Grinding Machine For Chemical Industry. Ball Mill Grinding Machine. About Company. Nature of Business Exporter and Manufacturer; Year of Establishment 1983; Legal Status of Firm Individual Proprietor; Annual Turnover Rs. 50 Lakh 1 Crore; Import Export Code (IEC) 03030*****

Get Price -

Planetary Laboratory Ball Mill Machine Grinding .

The planetary ball mill can use dry and wet methods to grind or mix solid particles, suspensions and pastes with different particle sizes and different materials. If a vacuum ball mill can be used, the sample can be ground and mixed in a vacuum or inert gas. This series of ball mills are widely used in geology, metallurgy, soil, building ...

Get Price