-

Rotary drum mill

PRODUCT ADVANTAGES PULVERIZATION OF LARGE SAMPLE VOLUMES The Drum Mill TM 500 is a laboratory ball mill designed to grind large sample volumes up to 35 l. It accepts initial feed sizes ... mill for the preparation of XRF/XRD samples XRDMill McCrone | <1 µm ball glass for metals Rotational speed: 1,000 rpm 1,500 rpm

Get Price -

Troubleshooting the Wire Feed System

· Increase the pressure only until it is very difficult to stop the wire from feeding out of the contact tip. Use a pliers or block of wood to try and stop the wire from feeding. Go perhaps onehalf of a turn beyond this point. When the wire is actually stopped, the drive rolls should spin on the wire and no nesting should occur.

Get Price -

ball mill will feeding drum

Mineral and Mining Engineering: What is the . · Ball Mill Working principle: PLC automatic control system Optional Accessories ( drum sieve, Hydraulic wrench mobile feeding settings)...

Get Price -

A new methodology to obtain a corrected Bond ball mill work .

Section snippets Material and experimental Bond tests. Samples of dacite and basalt from Serbia, copper ore from a South American metasedimentary copper mine, and copper porphyry ore from Canada, of different feed sizes, were used to determine the Bond ball mill work index according to the standard standard Bond laboratory mill with "DxL = 305 × 305 mm" balls .

Get Price -

Ball Mill Critical Speed

· A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell's inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula. The mill speed is typically defined as the percent of the .

Get Price -

Make a Ball Mill in 5 Minutes : 4 Steps

Wiki says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use in paints, pyrotechnics, and ceramics." Many instructables refer to United Nuclear Ball Mills. Their small ball mill cost between 70 and 80 dollars. For no more than 30 and in 5 minute you can build a ball mill of appreciable performance.

Get Price -

Chapter 18. Feed Milling Processes

Many feed mills pass all incoming ingredients through a grinder for several reasons: (a) clumps and large fragments are reduced in size, (b) some moisture is removed due to aeration, and (c) additives such as antioxidants may be blended. All of these improve the ease of handling ingredients and their storability.

Get Price -

Equipment For Mining Operations | Westpro Machinery

Westpro's heavy duty grinding mills are designed for durability and excellent grinding performance in mining appliions. Hopper Feeders Available as stationary, modular and portable units, Westpro's heavyduty Hopper Feeders are suitable for .

Get Price -

drum feeder in ball mill

Nov 26, 2019· The feed of the ball mill contains grinding balls. In order to effectively reduce the direct impact of materials on the ball mill feed bushing and improve the service life of the ball mill feed bushing, the feeding point of the groove in the feeding part of the ball mill must be as close to the side of the mill barrel as possible.

Get Price -

drum feed to ball mill

ball mill drum type coal feeder. Combined raw coal feeders Тяжмаш ball mill drum type coal feeder, Ball tube mills Mill of ShBM type with split drum Combined raw coal feeder is designed for its installation under raw coal storage Dozing machine is mounted under the raw coal hopper and provides the coal continuous feed from theTHERMAL POWER PLANT.

Get Price -

Ball Mill

High Energy Ball Mill Emax Feed material: mediumhard, hard, brittle, fibrous dry or wet Material feed size*: 5 mm Final fineness*: 80 nm No. of grinding stations: 2 Product details Planetary Ball Mill PM 100 Feed material: soft, hard, brittle, fibrous dry or wet Material feed size*: 10 mm

Get Price -

Building Ball Mill Drum

Ball charge management and maintenance. x x total weight approx. 6,800 kg with feeding hopper. the magotteaux drum ball sorter consists of a ball hopper, a vibrating feeder with variable feed rate, a drum sorting system and eight exit chutes. the ball sorter allows for sorting balls of either the first or second compartment.

Get Price -

HOW IT WORKS

Heavier oversized particles are held in the grinding chamber by centrifugal force, until micronized to a desired size. https:// Feed particle size is critical, restricted by the size of the feed injector. For mills of 200300 mm, the feed size can be a maximum of mm.

Get Price -

Pellet mill die and roll design

Feed Pelleting Reference Guide Section 1: Introduction Chapter 4: Pellet Mill Die and Roll Design the same in order to achieve the pellet quality required. They are also used for appliions such as shrimp feeds, where the length of the pellet is important and must be maintained. Figure 45. Types of die relief.

Get Price -

RPMs on a ball mill and a star rolling machine

rolling. The thing I'm confused about is the RPM of the drums. I always. thought a ball mill should be fairly slow because rock tumblers that I've. seen are fairly slow maybe 60 revs per minute. I guess I'm wrong. I've seen recommendations of much higher speeds. Of. course, that is the speed of the motor when the belt, wheel, and drum.

Get Price -

Grinding balls, buy metal balls from Metinvest manufacturer

A ball mill is a drumgrinding unit where balls from solid materials (steel, iron, hard alloys, ceramics, etc) are used. Most common are ball mills, where when the drum rotates and the balls rub against the inner walls, the balls are lifted until the lifting angle becomes bigger than the angle of repose. Then the grinding media are again below.

Get Price -

feeding balls to a ball mill

Ball mill Magnetic separation process. Ball mills are in many shapes: short drum one, long drum one, pipe one and Materials enter the first cabin of ball mills via the feeding device across the There is a scale board with steel balls in the second cabin which will grind price

Get Price -

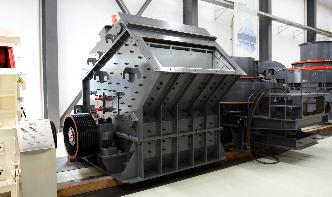

Ball drum mill. Design, structure diagram, operating principle ...

Specific charge of the mills is to t/m3 of the drum volume. The continuousaction drum mills discharged through a meshy end diaphragm are used in silie, ceramic and other industries. The material is charged into the mill by the feeder through an opening in the cover via which the material is fed into the mill drum.

Get Price -

USB2

B02C17/183—Feeding or discharging devices Abstract The present invention is directed toward a material handling, processing and milling facility which utilizes ball milling as a means for material...

Get Price -

CryoMill | Glen Mills, Inc.

The Autofill system avoids direct contact with LN2 and makes cryogenic grinding very safe. Its versatility (cryogenic, wet and dry grinding at room temperature) makes the CryoMill the ideal grinder for quantities up to 20 ml. You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input.

Get Price -

ball mill will feeding drum

Ball Milling University of Massachusetts Boston. 202049 Drum ball mills Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final fineness: ~ 5 µm Setting of vibrational frequency: digital, 3 30 Hz (180 1800 min1) get price

Get Price -

PERI™ AutoCharge Mill Grinding Ball Charging System

Each ball feeder/counter system is designed to accept a narrow range of ball diameters and should not be used to charge balls of mixed sizes. Weightbased counter The AutoCharge system's weightbased counter is suitable for all ball diameters but is particularly applicable to smaller ball sizes (50–80 mm), including ball recharge practice involving multiple sizes.

Get Price -

CNA

The invention relates to a drumshaped feeder of a ball grinding mill. A lining plate matched with an inner cavity of a cylindrical feeding shell and a threemouth spiral body are loaded from an open end of the cylindrical feeding shell, a feeding end cover is tightly connected with the cylindrical feeding shell by bolts, a circular material outlet WC, a boss in matching connection .

Get Price -

LUOYANG ZHONGTAI INDUSTRIES CO., LTD

Apron Feeder. BKC series Jaw Crush. Back pressure turbin. Ball mill cover. Bauxite Rotary Kiln. ... Full hydraul. YZS08 06 03 Double d. Single drum v. Single drum . YZC630H Fully hydrau. Rotary Dryer. More >> ENGINEERING AND MODERN TECHNOLOGY Luoyang Zhongtai Industries Co., Ltd. ... Overflow type ball mill sent to Baotou ...

Get Price -

CNB

The present invention relates to a kind of drum feeder for ball mills, the bottom lining plate and three oral spirochetes that coordinate with cylindrical shape feed housing inner chamber are packed into by the open end of cylindrical shape feed housing, and material feeding end bonnet bolt is closely connected with cylindrical shape feed housing; Boss and installation screw that .

Get Price