-

Ball mill and classifying production line of silica powder

· The preparation of crystalline powder, cristobalite powder, fusion powder and various active powders all need to go through a grinding and classifiion process. The grinding and classifiion of silicon micropowder generally adopts dry ball milling and classifiion. Ball Mill and Classifying Production Line

Get Price -

ball mill for silica powder

High energy ball milling process for nanomaterial It is a ball milling process where a powder mixture placed in the ball mill is subjected to high energy collision from the balls This process was developed by POSSIBILITIES OF THE WEAR CONTAMINATION DECREASING

Get Price -

ball mill to make mineral into powder

Ball milling is a mechanical technique that is broadly used to grind powders into fine particles . The reactants are generally broken apart using solvent molecules in the traditional method but in ball milling, reactants are broken by using mechanical forces. The term mechanochemistry has been introduced very recently . Get a quote

Get Price -

Common problems of ball mills and solutions to failures

· | By ALPA Powder 1. When the ball mill is running, there is a regular percussive sound, and the sound is loud. When the ball mill rotates, the liner hits the grinding cylinder of the ball mill. Judge the position of the liner of the ball mill according to the sound, find out the loose bolts and tighten them separately. 2.

Get Price -

dry ball milling process of aluminum flake powder

dry ball mill process of aluminum flake powder. Manufacturing of aluminum flake powder from foil scrap by dry ball milling process SeongHyeon Hong*, DongWon Lee, ByoungKee Kim Department of Materials Engineering, Korea Institute of Machinery and Materials, 66 Sangnam, Changwon, Kyungnam, 641010, South Korea Received 20 August 1998 .

Get Price -

High Energy Ball Mill For Sale | Vertical Milling Machine

All Powder Processing mm Yttria Stabilized Zirconia; mm Yttria Stabilized Zirconia; ~ mm Yttria Stabilized Zirconia; " (10 mm) Diameter Tungsten Carbide Dry Pellet Pressing Die Set; (500ml) Stainless Steel Roller Mill Jar 304 or 316 Grade; ~ mm Yttria Stabilized Zirconia

Get Price -

Design and Performance of Ball Milling for Powder Metallurgy Composites

method. The powder metallurgy route mainly consists of three stages, Mixing of the powders, compaction and sintering. The mixing can be achieved by many methods and one of such method is by utilizing ball milling equipment. The ball mill equipment consists of hollow cylinder filled with powders to be mixed and number of balls.

Get Price -

ball milling powdered

Ball mill ball milling ball grinder ALPA powder 2022 1 21 Ball Mill and Classifying Production Line. The world's leading technology mature technology stable operation low maintenance cost low unit energy consumption flexible selection of grinding media and liners high purity processing concentrated product size distribution and customizable solutions.

Get Price -

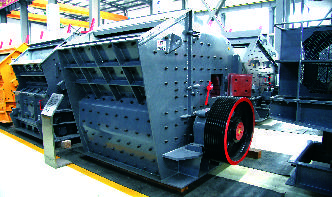

Ball Mill | Jet Mill | Powder Grinding Mill | Impact Mill .

Zhengyuan Powder Engineering Equipment Co., Ltd., a powder grinding mill manufacturer and supplier in China, provides a wide range of jet mills, impact mills, ball mills, roller mills, plastic pulverizers, and more. Various accessories for powder grinding equipment, like air classifiers, dust collectors and rotary feeders are also available.

Get Price -

Effect of BalltoPowder Ratio on Morphology, Structure, and ...

· It was found that ball milling smoothed the sharp edges and corners of the precursor powder and reduced the size of the precursor powder. As a result, the ballmilled powders have a more regular shape, more uniform size distribution, lower surface roughness, and better flowability than the precursor powder for thermal spray appliions.

Get Price -

Silicon Powder Properties Produced in a Planetary Ball Mill as a ...

· In this study a metallurgical grade silicon quality was milled in a planetary ball mill and the properties of the powder were investigated as a function of grinding time, grinding bead size (20 mm, 2 mm, mm) and rotational speed based on the concepts presented in the stress model. The finest powder was characterized by a d50 of μm.

Get Price -

Ball Mill Grinding

Ball Mill grinders are designed to reduce materials down to a fine powder, using the impact and friction created by a large quantity of balls – generally made from steel, but also available in other materials for specific appliions – which are placed inside a rotating mill to create a .

Get Price -

ferrite ballmilling fepowder

Influence of Iron Oxide Particles on the Strength of Ball ... and focus on the influence of oxide particles on the strength. ... 20014 222 200h milling milled powder .....

Get Price -

Zhengyuan Powder Equipment

The alloy media ball mill classifiion production line is a continuous largescale powder production line composed of energysaving superfine ball mill and selfsplitting classifier. The internal structure of the ball mill provides the most professional configuration according to the characteristics of the materials. Contact Our Team

Get Price -

nano herbal powder by ball milling process

nano herbal powder by ball milling process – Grinding Mill China Home 187 Product Appliions 187 nano herbal powder by ball milling process In high energy ball milling . Ball Pet wayfair com . Shop Ball Pet Today For Huge Savings amp Free Shipping . fine grinding of combined herbs nanoparticle .

Get Price -

Dry Ball Milling Process Of Powder

201511 In the wet milling process, the boron powder and tungsten carbide ball were put into the milling jar as in the dry milling process. Also, 15 ml of anhydrous hexane (SigmaAldrich, purity of 95%) as a solvent and 1 ml of oleic acid (SigmaAldrich, USA) as a coating material were added to the milling the grinding process ...

Get Price -

The effect of ball milling and rehydration on powdered mixtures .

· In many appliions, particularly in food related work, it is assumed that ball milling merely serves as a means of reducing crystallinity by the steady attrition of crystals. In this work mixtures of cellulose with other biopolymers have been coball milled in the dry state typically at moisture contents of <12% (w/w) and the effects of recrystallizing these mixtures studied.

Get Price -

Ball milling of powder mixtures

Ball milling is an effective and the common way to homogeneously blend the particulate reinforcement within a ductile matrix, aluminum, magnesium, copper, etc. [Har98]. In this process, the mixture of matrix and reinforcement powders and the milling media (hardened balls) are added in a container (also known as grinding vial, jar or bowl) under inert atmosphere .

Get Price -

ball mill a substance to very fine powder

Contribute to gcmcrusher/2022en12jzps development by creating an account on GitHub.

Get Price -

milling ball to powder ratio

· May 29, 2017 0183 32 Set it aside Grind the sulfur into a powder as well, and then set it aside It is very important to grind everything individually You may also choose to use a ball mill If this is the case, place your crushed charcoal and your sulfur in the mill, and run the mill for several hours Once ground to a fine powder, remove from the mill...

Get Price -

Ball Milling

Ball Milling For grinding powders. To learn more about ball milling, click here. from £ Ball Mill Tyres Custom tyres are made from vulcanised rubber, these will help rollers get a grip on the jar and reduce noise. Buy Now from £ Ceramic balls 13mm Ideal media for ball milling with smaller jars. Buy Now from £ Ceramic balls 20mm

Get Price