-

PHARMACEUTICAL TECHNOLOGY 1: EXPERIMENT : BALL MILLING .

· 1) of coarse salts were weighed. 2) Different sizes of steel balls were inserted to the mill. 3) The weighed salts were inserted into the mill. 4) The milling process was initiated with the speed of 10 within 20 minutes. 5) The product obtained is then weighed again after the milling process ended.

Get Price -

Ball Milling method for synthesis of nanomaterials

1. As the name suggests, the ball milling method consists of balls and a mill chamber. Therefore over all a ball mill contains a stainless steel container and many small iron, hardened steel, silicon carbide, or tungsten carbide balls are made to rotate inside a mill (drum). 2. The powder of a material is taken inside the steel container.

Get Price -

Influence of ball milling on the particle size and antimicrobial ...

Influence of ball milling on the particle size and antimicrobial properties of Tridax procumbens leaf nanoparticles ISSN ... γ00 rpm) in ball mill for different milling periods namely 6, 9, 1β and 15 h (hereafter termed, respectively, as sample TP6, TP9, TP1β and TP15). The synthesis of herbal nanoparticles from T. procumbens plant ...

Get Price -

OneStep Ball Milling Preparation of Nanoscale CL20/Graphene .

· A onestep method which involves exfoliating graphite materials (GIMs) off into graphene materials (GEMs) in aqueous suspension of CL20 and forming CL20/graphene materials (CL20/GEMs) composites by using ball milling is presented. The conversion of mixtures to composite form was monitored by scanning electron microscopy (SEM) and .

Get Price -

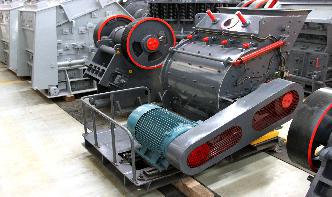

Crushers, Mills Grinders < Materials Handling

Displaying 36"Crushers, Mills Grinders" products/services. Balanced Roll Crushers(7 Companies) Ball Mill Suppliers(1 Company) Coal Breakers(1 Company) Cone Crushers(4 Companies) Construction Jaw Crushing Plants(1 Company) Crusher Parts(1 Company) Crushing Equipment (8 Companies) Crushing Mining Equipment(4 Companies) Crushing Plant(13 .

Get Price -

Hammer Milling | Hammer Mills | AVEKA

Hammer milling parameters such as screen size, blade selection and rotor speed can be optimized for each appliion, depending on the equipment used. The typical particle sizes that can be achieved with hammer mills is a D 50 between 150 μm and 600 μm. Hammer mills tend to yield less than 25% of particles below 150 μm.

Get Price -

Design, Construction, and Operation of a HighEnergy Mill for

· A highenergy mill was designed and built with the purpose of processing magnesium (Mg) powders. The main characteristics of the mill are grinding capacity of 1 kg and demolition elements of 10 kg; it has a distributed form to the interior ten blades of similar geometry, six of which are of the same size and four of them were increased in length in order .

Get Price -

Effect of planetary ball milling and solid sodium hydroxide on ...

Effect of planetary ball milling and solid sodium hydroxide on dissolution of rare earth elements from weathered residual rare earth ores. / Kato, Tatsuya; Giuseppe, Granata; Grabda, Mariusz et al. Proceedings of the 10th European Metallurgical Conference, EMC 2019.

Get Price -

Solids and powder milling

Ball mills (wet) Ball mills, as described above, are also a machine of choice for milling solids in wet phase. The design applied here is mainly a ball mill with an agitator, the movement of the agitator making the beads move and impact or friction the particles to be milled.

Get Price -

Effects of Ball Milling Processes on the Microstructure and .

· To investigate the effect of ball mill treatment of microcrystalline cellulose (MCC) on the rheological properties of MCCpolymer suspension, the structure and physicochemical characteristics of ground samples with different milling time and the rheological behaviors of MCCstarch suspensions were determined and comprehensively analyzed.

Get Price -

The Effect of Ball Size Diameter on Milling Performance

· An investigation was conducted to determine the effect of the ball diameter sizes on milling operation. A laboratory size ball mill was used with ball media of sizes 10 mm, 20 mm and 30 mm respectively. Quartz was the material used to perform the experiment and was arranged into 3 monosizes namely 8 mm + mm, 4 mm + mm and2 mm + mm for .

Get Price -

PowerMill Climber | Life Fitness

PowerMill Climber A smooth stepping motion and 26 different speeds make the PowerMill ideal for exercisers who prefer slow climbs or those looking for one of the most challenging and intense cardio workouts at the gym. The large step space and anti toepinch design ensure secure footing during everything from highintensity to moderate workouts.

Get Price -

Suriname Bauxite Ball Mill

Bauxite Machine HighSpeed And Fully Automated. mill machine bauxite ball mill machine lead ore ball mill. us / set. sets (min. order) 8 yrs shicheng county jinchuan mineral equipment manufacturing co., ltd. (2) contact supplier. moreover, according to different materials and discharging methods, there are dry ball mills and wet ball mills for choice. the .

Get Price -

Ball Milling

What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . Major parameters for ball milling ... Ball milling should be considered as a potentially attractive solution for solventfree synthesis. 21 Solvent free Onepot

Get Price -

QUICKLIME SLAKING PLANTS

Our Brands Call 1300 127 091 info About Us Company History Our Clients Environmental Misson Commitment to Safety TERMS CONDITIONS EQUIPMENT Equipment by type BALL CHARGING SYSTEMS BALL CHARGERS AUTOMATED BALL CHARGERS DRUM KIBBLES BALL MILLS BELT SCALES BIN ACTIVATORS BOOM SYSTEMS Bulk .

Get Price -

Influence of the milling parameters on the mechanical work .

for the 15 mm balls. In each milling experiment, the powder charge (Zn and Se powders in a 1:1 stoichiometric ratio) and the milling balls were placed in a 45 mL tempered steel vial (67 HRC) and were ballmilled under 6 bars of highpurity helium gas. The vial was purged with helium several times, and the pressure was selected prior to milling.

Get Price -

Effect of BallMilling Pretreatment on Microstructure and .

· Abstract. The effect of the ballmilling pretreatment on microstructure and corrosion of hotdip galvanized coatings was studied. The alloy layer thickness of the ballmilled (BM) sample is smaller than that of the pickled (P) sample, and there is no outburst structure in the coating of the BMsample.

Get Price -

CNC Milling | Machining Design Guidelines

Part features are recommended to be thicker than in. () in all regions and a nominal part thickness above in. () is required. Maximum depth that can be milled is 2 in. () from either side of part. For specific milling dimensions by material, see maximum part extents for machining.

Get Price -

4 factors that affect milling machining accuracy

Each mechanical devices are manufactured by a variety of components constitutedcomponents stiffness impact milling machining accuracy is major factors of affecting milling components ... Aug 18 2019 · Factors That Affect Ball Mill Grinder Capacity And Quality 7 factors that affect the output of ball mill machine The grain size of raw ...

Get Price -

Impact of planetary ball mills on corn stover characteristics and ...

· The impact of planetary mill pretreatment on corn stover size, crystallinity, and enzyme digestibility was investigated based on the grinding ball properties in an effort to reduce energy consumption. Alumina, zirconia, and steel balls were used, of which steel balls had the highest specific gravity but the lowest surface roughness while alumina balls had the lowest .

Get Price -

SpeedMixer™

Mixer Mill SmartSnap™. Ideal for: Large starting particle size (up to 25 mm ø) Main mode of grinding: Impact Shear force. l Built To Last Made in the USA. l Easy Operation Large touchscreen and intuitive user interface. l Efficiency. Typical grinding times: 30 sec 2 min. Grind up to 3 samples at a time.

Get Price