-

Limestone Slurry Preparation System

Ammonium Sulfate WFGD Technology OVERVIEW FOR MET. Limestonebased WFGD usually requires a fairly complex reagent slurry preparation system consisting of a limestone storage silo, weigh feeder, wet ball mill with all required accessory equipment, cyclone classifier, ball mill product sump with agitator, ball mill product pumps, limestone slurry tank and limestone .

Get Price -

Preparation of Paper Coatings

The clay or other pigment is normally supplied in bulk tankers as slurry containing 60% solids. Some paper manufacturers prepare the slurry themselves, dispersing the powder into water with conventional agitation. This is a relatively simple duty, however long mixing times may be required to produce each batch. Basic coating preparation can be summarized as follows:

Get Price -

Mine Slurry Transport

· In the crushing and preparation plant, crushed ore is mixed with water into slurry and then transported in pipelines to hydrocyclones where valuable minerals are separated from waste gangue. The slurry, with its average density of 1,300 kg/m³ and particle sizes up to mm, is not just any highviscosity mass.

Get Price -

limestone slurry preparation system

· ESP and FGD System Limestone Slurry Preparation System Know More. May 25, 2015 0183 32 The limestone slurry preparation system is for common use of 2 sets of FGD deviceThe limestone slurry preparation system is designed per uncer COAL E operation situation in 100 scope The limestone is transported by truck to grinding shop within .

Get Price -

SolventFree Manufacturing of Electrodes for Lithiumion Batteries .

· Lithium ion battery electrodes were manufactured using a new, completely dry powder painting process. The solvents used for conventional slurrycast electrodes have been completely removed.

Get Price -

Innovative Slurry Preparation and Applior System

Innovative Packtech Machines Private Limited Offering Slurry Preparation and Applior System at Rs 250000/piece in Greater Noida, Uttar Pradesh. Read about company. Get contact details and address| ID:

Get Price -

limestone milling slurry preparation system

Ball Mill Operation Grinding Circuit Startup amp Shutdown Procedure . 7 Sep 2017 Ball Mill and Grinding Circuit Preparation for Start UP The following items must Ensure that the plant air shut off valves are open to the mill clutch and ring gear lube system Also check the air Check that the lime slurry pump is in operation circulating lime slurry around the mill loop Also ensure that .

Get Price -

Bentonite Uses In Piling

Bentonite clay is a mined product. Usually, two types of bentonite, sodium and Calcium based, are found in our nature. Sodiumbased bentonite is used for soil stabilisation work. For piling works, bentonite powder shall be mixed with water to make a slurry with specified parameters, and the bentonite slurry is used to stabilise the sides of the ...

Get Price -

Chromatography column packing | Cytiva

A slurry recipe can be generated with packing solution recommendations for ÄKTA chromatography systems with Intelligent Packing support for AxiChrom 50 to 200 columns. The recipe is valid for slurry concentration measurements performed with resin in 20% ethanol that has settled by gravity. The method controls the flow rate of hydraulic fluid to drive the adapter .

Get Price -

Wet Blasting and Slurry Blasting Machines | Rapid Prep

The Rapid Prep Greener Blast is a highperformance slurry blasting system built for maximum production, requiring a minimum of 375 CFM to operate with the ability to handle upwards of 1,500 CFM; more air equals more production. This highperformance slurry blaster is capable of driving nozzles ranging from #6 to #12, while blasting at pressures ...

Get Price -

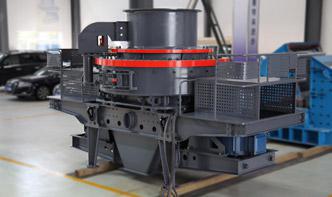

crusher lime slurry preparation system

nbsp 0183 32 Since the slurry preparation system is tied into a pipeline equipped with slurry pumps there is a need to limit the size of slurry particles to a maximum of about 8 inches Otherwise stated the solids in the slurry need to be sized so as to be pumpable . limestone preparation system for fgd – Crusher Machine . limestone preparation system for fgd is .

Get Price -

® PC and PCH | Group

Limestone Preparation; Sugar; Food; Dewatering; Tunnelling; Processes. Slurry transportation; Mine Dewatering Systems; Specifiion. Design standards . Hydraulic Institute 6, ISO 9001, ISO 14001, OHSAS 18001 CE certified. Design ratings . N/A. Size range/dimensions. Discharge size 100mm to 300mm. Pressure class/power. Heads to 395 ft (120 m) Pressures to 245 psi .

Get Price -

2: Preparation of TLC Sheets and Plates | Engineering360

The applied slurry was allowed to set and dry for about 30 minutes. Final activation was completed in an oven for 30 minutes at a maximum temperature of 105 C. To improve the binding of the silica gel to the inert backing a gypsum binder was added; Stahl recommended 13% of calcium sulphate. Although the layer was soft and easily damaged, it ...

Get Price -

Slurry Spray System

Slurry Spray System ClogFree tm Spray Coating Spray virtually any pumpable slurry, including sugar, syrup, chocolate, oil, or emulsion. Engineered for cereal, snack and pet food appliions to maximize coverage and minimize waste. Our ClogFree spray station design prevents nozzle plugging. Available for use in coating drum and conveyor belt appliions. Standard Features .

Get Price -

INTEGRATED DESIGN OF PREPARING SYSTEM FOR DESULFURIZER SLURRY .

The desulphurizer slurry preparation system directly prepared with limestone powder is an important part of dry preparation system of desulphurizer slurry in limestonegypsum FGD integrated design of the limestone slurry tank and limestone powder silo was proposed according to the shortcomings of conventional desulphurizer slurry preparation .

Get Price -

Slurry Buyers importers directory of Bolivia

Choose from 3 profitable active Slurry buyers in Bolivia with shipment import Price, supplier, qty, phone, email Linkedin directory.

Get Price -

® MU | Group

Limestone Preparation; Sugar; Food; Dewatering; Processes. Slurry transportation; Mine Dewatering Systems; Specifiion. Design standards . Hydraulic Institute 6, ISO 9001, ISO 14001, OHSAS 18001 CE certified. Design ratings . N/A. Size range/dimensions. Discharge size 80mm to 200mm. Pressure class/power. Heads to 230 ft (70 m) Pressures to 145 psi .

Get Price -

Preparation scheme of positive and negative electrode slurry for ...

· As the mainstream solution for automotive power batteries in recent years, lithium batteries have many production processes. There are various solutions in the equipment industry for each process, and new solutions are constantly entering with the development. The production of lithium batteries is divided into three stages: pole piece production, cell assembly, and .

Get Price -

Products

Spray Chamber, SlurrySpectro. Item: . Unit of measure: ea. Description: Conical spray chamber, slurry, open end. Promo: FREE pack of PlasmaFLOW PVC pump tubing or FREE ICP Standard* (single element, 1,000 ppm, 2 x 25 ml) with the purchase of a PlasmaFLOW product; including nebulizers, spray chambers, torches and ICPMS cones ...

Get Price -

Dewatering Chemicals Preparation | PHOENIX Process Equipment

PLC controls interface with plant computer systems and the systems can be supplied with automatic or manual controls for maximum operational flexibility. Dewatering Chemicals PHOENIX also provides a full line of costeffective polymers for slurry thickening, slurry dewatering, slurry pond maintenance, and water clarifiion.

Get Price -

Guidelines, Bulletins Pocket Guides

Download the A165 Guidelines. Recommended Performance Guideline for Crack Treatment. Download the A175 Guidelines. Recommended Performance Guideline for Emulsified Asphalt Slurry Seal. Download the A105 Guidelines. CODE: TB100. TITLE: Laboratory Test Method for Wet Track Abrasion of Slurry Surfacing Systems.

Get Price -

colloidal silica CMP slurry

slurry delivery system [3] in a 200 ft, 3/4in. PFA tubing global distribution loop for 162 hr (~2770 turnovers turnovers/hr). In a second test, the slurry was recirculated in a Nippon Pillar PE20MAN doublebellows pump for 42 hr (~2520 turnovers 60 turnovers/hr). Therefore, the VPDS and pump tests were continued for a comparable number of turnovers. The pointofuse .

Get Price -

Abrasive Blasters – Wet Abrasive Blasting Equipment

· Graco abrasive blasters are ideal for blasting in areas where dust and containment are concerns. Wet and vapor abrasive blast systems employ a mixture of water, air, and abrasive to clean and remove surface contaminants and coatings. This method is ideal for surface preparation and provides a cleaner surface with little to no embedded particles or clinging dust.

Get Price -

Cryosectioning tissues

· The preparation of cryosections does not involve the dehydration steps typical of other sectioning methods, and, furthermore, sectioning, labeling, and observation of specimens can usually be carried out in one day. In general, the sample is frozen quickly in either isopentane or liquid nitrogen. (Small samples such as cells and small tissues may be mixed in a slurry of .

Get Price -

Slurry

A slurry is a mixture of denser solids suspended in liquid, usually water. The most common use of slurry is as a means of transporting solids or separating minerals, the liquid being a carrier that is pumped on a device such as a centrifugal pump. The size of solid particles may vary from 1 micron up to hundreds of millimeters. The particles may settle below a certain transport .

Get Price