-

Steatite Ceramic Grinding Balls and Media | Steatite ceramic .

Steatite ceramic balls and mill lining bricks are manufactured from the same finegrained composite and are ideal performance partner. Thus, they retain their shape better and last longer than flint / river pebbles, natural stones, porcelain etc. Due to their higher density, hardness, toughness and a higher degree of sphericity, Steatite ceramic grinding media saves over 20 .

Get Price -

Grinding ball mill, Ball mill machine, Ball mill manufacture

Cement Industry. Cement ball mill is the equipment of cement plant. It is mainly used for grinding various cement clinker and other materials in building materials, metallurgy, electric power and chemical industries. Our company can design and manufacture special cement ball mill according to the output and fineness requirements of users.

Get Price -

Manufacturing process of ceramic tiles

08/11/2016 · As a general rule, the more color and design involved, the longer the tiles are heated. Typical firing temperatures for alumina, mullite, and zirconia reach 2850 °F 3100 °F. Typical firing cycles can range from 12 120 hours depending upon the kiln type and product. Ceramics shrink approximately 20% during the sintering process. 15.

Get Price -

Make a Ball Mill in 5 Minutes : 4 Steps

Wiki says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use in paints, pyrotechnics, and ceramics." Many instructables refer to United Nuclear Ball Mills. Their small ball mill cost between 70 and 80 dollars. For no more than 30 and in 5 minute you can build a ball mill of appreciable performance.

Get Price -

Three Common Problems and Solutions In Ball Milling Processing

01/06/2020 · Two. Ball mill is easy to throw out pulp through throat. During the normal ball milling process, pulp is thrown out from throat with small stones. Reasons and countermeasures: (1)Imbalance of watermaterial ratio in ball mill. The water amount in ball mill cylinder is an important index in ball milling process.

Get Price -

Manufacturing process of ceramic tiles

06/09/2015 · 14. Tiles are generally used for covering roofs, floors, walls and ceilings. They are commonly made of ceramic or stone. Major Part of the manufacturing process involves powder metallurgy. The raw materials are mixed in correct proportion and sent to ball mill for slurry preparation. The slurry is then passed to spray drier for making into ...

Get Price -

Ball Mill

The ball mill contains a hollow cylindrical shell that rotates about its axis. This cylinder is filled with balls that are made of stainless steel or rubber to the material contained in it. Ball mills are classified as attritor, horizontal, planetary, high energy, or shaker. View chapter Purchase book Mechanical Crushing and Grinding

Get Price -

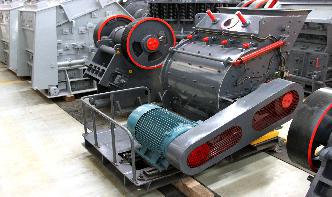

Ball Mill Ball Mills For Grinding Ceramic Stones To Powder

ball mills for grinding ceramic stones to powder; ball mill. Processing capacity:84394t/h. Feeding size:≤15mm. Appliable Materials: cement,newtype building material,fertilizer,ore,construction rubbish,ceramics etc. All grindable materials, various metal ores, nonmetallic ores, nonflammable and explosive materials

Get Price -

Ball Mill | Ball Mills | Wet Dry Grinding | DOVE

DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h1000 g/h). For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity range of ( TPH – 80 TPH). With over 50 years experience in Grinding Mill Machine fabriion, DOVE Ball Mills as ...

Get Price -

How To Install Steel Ball In A Ball Mill

24/06/2020 · The ball mill is a common mineral processing equipment. It is the quality assurance of the mineral process and related to production efficiency and product quality. ... From limestone to basalt, and stone production to various ore crushing, ceramic ball mills are indispensable. 0624 2020 The choice of sludge dryer models Sludge dryer is one of ...

Get Price -

Ball Mill Archives

Products. Being a leading company in heavy Industrial processing, Engineering Stone crushing, Construction Sand Making, organic fertilizer making and compound fertilizer making, EMCC is a hightech mining machinery and fertilizer machinery company in China. Our service has expanded to the entire world, almost including 75 countries.

Get Price -

1725 rpm ball mill sand processing

06/11/2021 · Used Stoneware Ceramic Ball Mill, 52 Gallon. Used Stoneware Ceramic Ball Mill, 52 Gallon. Approximate 33" diameter x 28" long, dished ends. Inlet outlet with cover. Driven by a 3hp, 3/60/208230/460 volt, 1725 rpm motor, with Stearns brake and a gear reducer to 1. Mounted on carbon steel legs with a discharge housing. Serial ...

Get Price -

Comparative Study on Improving the Ball Mill Process Parameters ...

19/02/2021 · The optimum process parameters setting concluded that balls to powder weight ratio are 20:1, the optimum ball mill working capacity is 2 L while the optimum speed of the ball mill is 105 rpm. Using SEM characterization, the improved particles of silica sand presented a spherical shape with a cluster.

Get Price -

Telematrix Engineers Consultant

Ball Mill Process Equipments 1) Pebble Mill. Lined with bricks and utilizes Pebbles or Balls as Grinding Media. It is milling machine for wet and dry milling. They are also lined with burrs tone (silica), alumina, steatite, ceramic,porcelain, urethane rubber etc. 2) Steel Ball Mill. It is used for DRY as well as LIQUID grinding.

Get Price -

Ball mill

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. T

Get Price -

sales of ceramic balls for ball mill

gold crushing plant processing search results. ponsel crusher harga mayotte search results. crusher hammer corn crusher bijih besi search results. natural stone proposed search results. parts diamond crusher search results. specific gravity of 20 mm metal search results. automatic sand molding machinery china search results

Get Price -

ball mill for kg sand processing

29/06/2022 · project report of stone crusher in excel ; basalt fertilizer price ; impact hammer crusher,hot selling impact crusher ; what are the raw material used for production of concrete ; ... Ball Mill Sand Processing Plant | Crusher Mills, Cone,

Get Price -

Process Of Sand In Ball Mill

sand ball mill process. stone crusher,stone crusher machine,ball mill,ball mill for . Last year, we bought energy saving ball mill, they have the best after sale service and pacient guide. ... Ball Mill Capacity Make Sand Processing Indian Stone crusher. Popular Q A About Ball Mill Capacity Make Sand Processing. CIROS plant is the largest ...

Get Price -

Used Ball Mill For Sale | Ball Mill For Sale | Phoenix

700 HP Allis Chalmers Ball Mill. Used 700 HP Allis Chalmers 10ft x 14ft (3m x ) Ball Mill. 2pc Helical Bull Gear, 13' diameter, 16" Wide Face, 310Teeth. Helical Pinion Gear, 16" Wide Face, 19Teeth. Rubber Liners, approximately 60% life remaining. Trunnions in Good Condition. Babbitt Bearings.

Get Price -

BALL MILL GRINDER

Ball mill is one of the most variable and effective grinding machines which is mainly applied for further grinding the crushed materials. Compared with other grinding mills, the variety of grinding modes, available grinding tool materials, and flexible production capacity make ball mill grinders the perfect match for a vast range of appliions, such as cement industry, new building .

Get Price -

Microcrystalline Ceramic Grinding Media Ball For UltraFine .

The double sintering process used in manufacturing our media results in superior strength and wear resistance with consistent particle size and shape. The unique chemical composition of QMX Ceramic grinding media produces the durability and density that make it ideal for use in both vertical and horizontal mill operations.

Get Price -

Ball Milling

28/07/2015 · I just finished making a direct drive ball mill on the cheap. I'm milling my first batch of material. I have stainless steel ball bearings (1/4 ",1/2", and 3/4" dia.) in the drum. ... I run ceramic balls in the mill. Granite dust to 80 mesh to fines in 6 hours. ... today's material processing. I also remember a workshop where the potter lowered ...

Get Price -

Ball Mill For Sale – Various Ball Mill Grinder Solutions | AGICO

WHO WE ARE. AGICO Cement is a largescale ball mill manufacturer in Henan, China. Founded in 1997, AGICO Cement has grown into a jointstock enterprise integrating independent design, R D, production, and sales. Our ball mill grinders have passed the certifiion of ISO9001:2008 international standard quality management system, wellsold ...

Get Price -

Wet Ball Mill Sanding Floorball Mill

Ball mill is the key milling equipment after materials has been crushed. It is widely used in cement, silie, new construction material, refractory material, ferrous metal and nonferrous metal as well as ceramics.

Get Price -

Zirconia Grinding Balls | Vostosun

Zirconia grinding ball can be used as generic grinding medium for sand grinding mill, vertical agitator bead mill, horizontal rolling mill, vibratory ball mill, bead mill and ball mill. It is suitable for ceramic raw materials, pigments, electronic slurry and battery materials such as silkscreen ink with high solid phase, offset ...

Get Price