-

coal mill hydraulic system principles

Polysius Roller Mills. For grinding. 4 Advantages of Polysius roller mills at a glance: xHigh operating reliability and availability, as well as easy system handling, due to the fact that grinding, drying and separation all take place in a single compact unit. xConsistently high product quality with minimum energy requirement, due to the integrated highefficiency

Get Price -

Stacker Reclaimer Operation And Their Parts | Coal Handling Plants

13/11/2016 · Modes Of Operation Of Stacker Reclaimer. 1. Stacking. The material on the forward moving yard conveyor is raised by the tripper and discharged through a discharge guide chute onto an intermediate inclined conveyor which lift the material and ultimately discharges on to the boom conveyor by a chute. The boom conveyor carries the material up to ...

Get Price -

roller tire coal mill coal fired power plant

coal fired power plant operation pictures. Navajo Generating Station Wikipedia Navajo Generating Station was a 225gigawatt 2 250 MW coalfired power plant loed on the Navajo Nation near Page Arizona United StatThis plant provided electrical power to customers in Arizona Nevada and CaliforniaIt also provided the power for pumping Colorado River water .

Get Price -

How Do Wind Turbines Work? | Department of Energy

A wind turbine turns wind energy into electricity using the aerodynamic force from the rotor blades, which work like an airplane wing or helicopter rotor blade. When wind flows across the blade, the air pressure on one side of the blade decreases. The difference in air pressure across the two sides of the blade creates both lift and drag.

Get Price -

coal handling process in animation

Jan 01, 2011· The process of from big to small .Currently mediumsized power plant coal handling system used in coal crusher, structural characteristics can be divided Hammer, Impact, and other types of hammer ring, hammer coal crusher due to its large strengths, highefficiency features, used more often. a Operation and maintenance of ...

Get Price -

Map of Coal Power Plants in the US [Interactive]

25/06/2022 · The steam is used to turn turbines, which generate electricity. Coalfired power plants are the largest source of greenhouse gas emissions in the United States. The history of coal power plants in the United States. Coalfired power plants have been in operation in the United States since 1882. The first plant opened in New York City.

Get Price -

Cogeneration Power Plant

Cogeneration or Combined Heat and Power (CHP) is the combined generation of heat and power. It is not a single technology, but an integrated energy system. Cogeneration first involves producing power from a specific fuel source, such as natural gas, biomass, coal, or oil. During fuel combustion, cogeneration captures the excess heat which would ...

Get Price -

coal mill operation power plant

Main parts of a thermal power plant. Working. Plant layout ... The coal is carried out of the mill by the flow of air moving through it. ... Basic Operation : A thermal power plant basically works on Rankine cycle.

Get Price -

stages of coal crushing

Coal Crushing Cone Animations Of Coal Crushing Procedures. Direct Method Determination Of The Gas Content Of Coal. crushing the coal sample in a by direct method, cm3 jaw crusher within a sealed, figure 1. gas content of coal versus actual mine emission. clear plastic box the box was purged of air prior to crushing and filled with nitrogen. the operator .

Get Price -

Coalfired power station

A coalfired power station or coal power plant is a thermal power station which burns coal to generate electricity. Worldwide there are about 8,500 coalfired power stations totaling over 2,000 gigawatts capacity. They generate about a third of the world's electricity, [1] but cause many illnesses and early deaths, mainly from air pollution.

Get Price -

CoalFired Power – Analysis

Of the 140 coalfired power plants in operation, more than twothirds (representing ~50% of installed coal capacity) will be retired. Around 5 GW of new ultrasupercritical and integrated gasifiion combinedcycle plants will replace some of the retired capacity. In Germany, ~EUR billion will be awarded to lignite power plant companies ...

Get Price -

coal mill operation in a power plant

coal mill operation in power plant; ball type coal mill used in power plant; basic steps involve in coal sed thermal power plant; mill manufacture for coal power plant; appliion of coal mill in power plant; ABOUT US. Widely renowned as Aggregate Crushing Specialists,manufacture a Crusher Range to suit any operation. Offering Jaw Crushers to ...

Get Price -

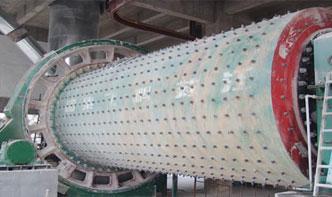

Vertical Coal Mill

Product Profile. Vertical Coal Mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and other fields. Its special design structure and production process creates the higher production efficiency with lower energy consumption, less dust, lower noise than ball mill, which ...

Get Price -

Coal Mill Modeling by Machine Learning Based on onSite .

01/08/2002 · This paper presents a novel coal mill modeling technique using genetic algorithms (GA) based on routine operation data measured onsite at a National Power (NP) power station, in England, The work focuses on the modeling of an Etype vertical spindle coal mill. The model performances for two different mills are evaluated, covering a whole range of operating .

Get Price -

coal mill operation in power plant

A unified thermomechanical model for coal mill operation ... Nov 01, 2015· Further, the performance and availability of the plant is influenced by several faults occurring in the milling system and various mill related factors such as incorrect fineness, improper air/fuel ratios, coal hang up at the mill inlet, overloading, fire /explosion, and wear of milling components .

Get Price -

Cogeneration: production of heat and power | Planète Énergies

Combined Cycle Gas Turbine Power Plants. See EDF animation (in French). In France, gasfired thermal power plants have gradually replaced fueloil and coalfired models. The newgeneration facilities are themselves evolving into combined cycle gas turbine (CCGT) power plants. CCGT plants are based on a simple principle (see diagram below):

Get Price