-

Raw Material Handling and Storage

29/05/2010 · With that in mind, the storage and handling of raw materials will play an important role in determining a plant's layout and equipment needs. Let's take a look at storage and handling requirements of concrete raw materials one at a time. Aggregate. When designing a plant's layout, the first thing to consider is the actual amount of ...

Get Price -

Material Masters: Le Corbusier's Love for Concrete | ArchDaily

04/12/2014 · In many ways, it was the poetically raw, elemental nature of concrete that Le Corbusier responded to. In Towards a New Architecture, he writes, "You employ stone, wood and concrete, and with these ...

Get Price -

Fibre Cement Facades and the Raw Material Trend – MSA Hub

21/06/2021 · The Influence of Brutalism. Raw cement and concrete were made popular through the Brutalist architectural movement, which embraced inexpensive, durable and functional building materials in the postwar climate from the 1950s to the 1970s.

Get Price -

Construction Materials Testing

The quality and consistency of the raw materials ultimately affect the finished product and, as such, great care should be given to the assessment of these materials. Mistakes made at this stage of the manufacturing process often remain to dog the product throughout its life, none more so than in the construction sector.

Get Price -

CONCRETE. RAW MATERIALS ppt

Concrete can be classified as composite material and that is a combination of different components which improve their performance properties. In general case binder component which can be in hard crystalline or amorphous state is considered as the matrix of composite material. In concrete matrix phase the grains of aggregates (dispersed phase) are

Get Price -

Import of cement raw materials rises | The Daily Star

2 days ago · Clinker, the main raw material, cost per tonne on an average in August. The price has effectively gone up per cent yearonyear. The price of 50kilogramme bags of every brand has been ...

Get Price -

How Is Cement Produced in Cement Plants | Cement Making .

The proportioning of cement raw materials is not all the same but should be determined according to the actual situation. The proportion of raw materials of different specifiions of cement is also different. Generally, the proportion of components in cement raw materials is 6775% limestone, 1015% clay, % iron ore and % coal.

Get Price -

Raw Materials – Olympic cement Limited

The quality of cement mainly depends on its raw materials (Clinker, Gypsum others) quality. To produce Anchor Cement we import highquality raw materials from Thailand, Indonesia, Vietnam, China and Japan regularly. The quality of raw materials has to confirm by pre shipment inspection by SGS before import. All imported raw materials reached ...

Get Price -

Alternative fuel and raw materials

The cement making process is energy and material intensive. Traditionally, fossil fuels and natural raw materials have been used to make clinker, the main ingredient in cement. To operate its business in a more environmentally, economically and socially beneficial way, Holcim is increasingly using nontraditional or "Alternative Fuels and Raw ...

Get Price -

Sustainable Building Materials

Geopolymer cement is based on inorganic materials with a polymer structure of molecules. Geopolymer binders and concretes are highstrength and possess a range of specific properties. They are called "geopolymers" because the raw materials used for their production are mainly minerals of geological origin.

Get Price -

CEMENT RAW MATERIALS

The quality of cement clinker is directly related to the chemistry of the raw materials used. Around 80–90% of raw material for the kiln feed is limestone. Clayey raw material accounts for between 10–15%, although the precise amounts will vary. Magnesium carbonate, which may be present in limestone, is the main undesirable impurity. The level

Get Price -

USE ALTERNATIVE RAW MATERIALS FOR CONCRETE .

17/12/2015 · The samples are crushed to obtain a different gradient to use in the production of lightweight concrete, this gradient according to ASTM C330/C330M [13]. The dry density, absorption, and thermal ...

Get Price -

Properties of Cement Physical Chemical

Chemical analysis of cement raw materials provides insight into the chemical properties of cement. Tricalcium aluminate (C3A) Low content of C3A makes the cement sulfateresistant. Gypsum reduces the hydration of C 3 A, which liberates a lot of heat in the early stages of hydration. C3A does not provide any more than a little amount of strength.

Get Price -

Different materials used for Precast Concrete Buildings

17/07/2020 · SCMs augment cement's actions and can improve fresh concrete characteristics, strengthen hardened concrete properties and reduce raw material costs. Supplementary cementitious materials include fly ash, ground granulated blast furnace slag, metakaolin and silica fume. They should comply with the requirements of the appropriate parts of IS ...

Get Price -

Concrete

16/12/2016 · 4. Concrete is mainly composed of Portland cement, Aggregate (Filler), Water and chemical Admixtures. Concrete = Filler + Binder Concrete is versatile construction material. The name concrete comes from the Latin word "Concretus" (meaning compact or condensed). Concrete solidifies and hardens after mixing with water and placement due to a ...

Get Price -

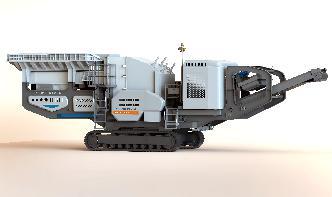

Why Do We Grind The Cement Raw Materials

Crushing Of Raw Materials For Cement. Crushing and grinding of raw material of cement. AP42 CH Portland Cement Manufacturing EPA. The initial production step in portland cement manufacturing is raw materials acquisition. to the process during the finish grinding operations described below. . at cement plants include 1 quarrying and ...

Get Price -

RAW MATERIALS FOR CEMENT MANUFACTURING

Raw materials for the production of cement. Minerals of natural origin as well as industrial products can be used for the production of cement. Starting material for this purpose are mineral compounds containing the main components of cement: lime, silica, alumina and ironoxide. Seldom are these components present in the needed proportion in ...

Get Price -

Cement Manufacturing Process | Phases | Flow Chart | Cement

30/08/2012 · Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sand clay fulfill the need of silicon, iron and aluminum.

Get Price -

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant | Cement .

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into .

Get Price -

Calculate Quantities of Materials for Concrete Cement, Sand, .

🕑 Reading time: 1 minuteQuantities of materials for concrete such as cement, sand and aggregates for production of required quantity of concrete of given mix proportions such as 1:2:4 (M15), 1:: 3 (M20), 1:1:2 (M25) can be calculated by absolute volume method. This method is based on the principle that the volume of fully compacted [.]

Get Price -

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant | Cement .

The main motor drives a millstone by rotational speed reducer, at the same time the wind enters into the raw mill from the air inlet, material through the screw feeder fell in the middle of the raw mill, under the action of centrifugal force, the raw materials move uniformly from central to the edge of the millstone, the materials will be ground by the roller when it passes through the ...

Get Price -

Concrete: the most destructive material on Earth

25/02/2019 · Phil Purnell, a professor of materials and structures at Leeds University, said the world was unlikely to reach a "peak concrete" moment. "The raw materials are virtually limitless and it ...

Get Price -

Concrete Mix Ratio and How to Mix Concrete | DIY Doctor

Cement can be bought (mostly in 25kg bags, although some stores still sell 50kg bags) from all builders merchants. It is crushed limestone, blended with other raw materials (sometimes shale and or sand) ground into a powder and then heated in a kiln.

Get Price -

7 Architectural Materials Inspired by the Raw Beauty of Concrete

Old Cotto by Stone Source. This material plays to concrete's handwrought construction methods with seemingly irregular tiles that speak to an oldworld aesthetic. Artesia by Stone Source. The concrete tile of the Artesia series takes an atypical approach to wall tiles.

Get Price -

A review on ultra high performance concrete: Part I. Raw materials .

30/12/2015 · Fibers used in UHPC are often micro steel fibers with length of 13 mm and diameter of mm. Optimization of raw materials results in required performance of UHPC. The following sections discuss the raw materials of UHPC in details. Cementitious components. Cement content in UHPC is generally about 800–1000 kg/m 3. The high cement ...

Get Price