-

StressIntensity Factors for Internal and External Surface Cracks .

· The finiteelement models employ singularity elements along the crack front and linearstrain elements elsewhere. The models had about 6500 degrees of freedom. The stressintensity factors were evaluated from a nodalforce method. The present results were also compared to other analyses of surface cracks in cylinders. The results from a ...

Get Price -

Ball mill trunnion

The ball mill trunnion is a key part to support and connect the cylinder, and is also the inlet and outlet channel of the material. CHAENG adopts highstrength steel and unique heat treatment technology, which makes ball mill trunnion have high hardness a . WhatsApp: +; Email: casting; English Español Русский العربية. .

Get Price -

Ball Nose Milling Strategy Guide

· Ball Nose Milling Without a Tilt Angle. Ball nose end mills are ideal for machining 3dimensional contour shapes typically found in the mold and die industry, the manufacturing of turbine blades, and fulfilling general part radius properly employ a ball nose end mill (with no tilt angle) and gain the optimal tool life and part finish, follow the 2step process .

Get Price -

Mill Cylinder For Mixing Rubber Compound, Ball Mill

Mill Cylinder For Mixing Rubber Compound Whatever your requirements, you 'll find the perfect serviceoriented solution to match your specific needs with our are here for your questions anytime 24/7, welcome your consultation.

Get Price -

Agglomeration of Powder

Chen Ding, ... HuangPeiYun, in HighEnergy Ball Milling, 2010. Effect of process control agents on solid–liquid reaction ball milling. A process control agent (PCA) is usually used in the process of mechanical alloying to avoid cold welding and bonding between the powder particles and the balls and the agglomeration of powder during milling, which is also noticeable for .

Get Price -

Understanding the root causes of axial cracking in wind turbine .

· An axial crack failure of the inner ring can be caused by excessive hoop stresses during installation but this does not appear to be the general case in the wind industry. Microscopic, whitecolored areas at the edge of the cracks when the bearings are sectioned and etched are a key indior that this is not merely standard hoopstress failures.

Get Price -

Cracking Down on Block Fillers

· Cracking Down on Block Fillers By "Animal Jim" Feurer on Jul 24, 2014 Here is a shot of Jim's 'Monolith' 672 which actually ran its best in 1989 with a cracked cylinder. In earlier articles, I mentioned filling dedied, drag racing iron blocks to keep cylinders round and keep them from cracking. Many drag racers still practice that modifiion.

Get Price -

Methods of measuring surface finish

The methods used for measuring the surface finish is classified into. 1. Inspection by comparison. 2. Direct Instrument Measurements. 1. Inspection by comparison methods: In these methods the surface texture is assessed by observation of the surface. The surface to be tested is compared with known value of roughness specimen and finished by ...

Get Price -

Procedure for Inspection Pistons and Cylinder Liners

· Keep the cooling water and cooling oil circulating, so that possible leakages can be detected. • Block the starting air supply to the main starting valve. • Open the indior valves. • Engage the turning gear. • Remove the inspection covers on the camshaft side of the cylinder frame, and clean the openings.

Get Price -

Lathe – ballturning, spherical surfaces, concave and convex

A round concave cutting edge will cut a convex surface. On a small lathe, the power and rigidity of the lathe will limit the length of the cut even if the depth of cut is relatively short. 2328 ball turning. fig using a form tool made from a piece of HSS. Very often the .

Get Price -

OF MINERAL FINES PRODUCED R. ROUSSEV Bnd P; .

In addition to ball mill grinding, powders were produced by an impac' tester, ~rtar and pestle and by hand rubbing in a B>rtar. Characterization of the ground products was done by sieving to obtain the size distribUtion, quantasorb surface area analyzer, scanning electron microscopy and by packing in a cylinder (2) to obtain porosity of the poWer assembly. The above .

Get Price -

Milling Balls

Grinding Media. Grinding media are the means used to crush or grind material in a mill. It comes in different forms such as alumina oxide balls, ceramic cylinders, or soda lime glass. At Norstone Inc., we offer all types of medias used for grinding, deagglomeration, polishing, deburring, fillers, proppants, spacers, refractory beds and shot ...

Get Price -

Ball Mill Crack Repair

Ball Mill Shell Crack Welding Mine Equipments. diffusion engineers limited cement mill shell crack reconditioning Mill Type is Ball mill Mill Length is 16035meters and Dia is 34meters Base Material is Cast Activity C clamps were welded horizotaly along. read the mill crack repair fix cracks in industrial ceramic ball mill thedugongcoza. Repair .

Get Price -

Comminution testing

An improved method using less mass compared to the Bond Ball Mill Work Index test. The JK Bond Ball Mill (JKBBM) test, is a locked cycle grindability test conducted using a standard laboratory Bond Ball Mill with the same steel ball charge and material feed size ( passing mm) as the Bond Ball Mill Work Index test. The test requires approximately 50% less .

Get Price -

Basics of End Mills

Milling cutter A rotary cutting tool having many cutting edges on the periphery or an end face of a cylinder and a cone. Drill A tool for drilling. Cutting edges are only on a top. End mill A multifunctional tool which has cutting edges on the periphery and an end face. Side milling, curved surface milling and drilling are possible only by one ...

Get Price -

Cylinder Head Rebuilding Tools | Goodson Tools Supplies

Home » Cylinder Head Rebuilding Tools Cylinder Head Rebuilding Tools This egory includes everything from Pilots to Valve Seat Stones to Valve Refacer Wheels to Reamers to Spring Compressors to Crack Detection Repair and much more. Sort by SuperStud™ Stud Installers BCT1/2 : 1/2" HeadBolt Cleaner/Deburring Tool

Get Price -

POLYCOM highpressure grinding roll

forged and hardfaced profiling hard buildup welding base metal ductile base metal, insensitive to stresses and cracking moderate wear most economical solution many years of experience achieved service life 8,000 – 22,000 hours compound casting profiling hardfaced layer base metal very long service life well suited for highly abrasive materials .

Get Price -

BEARING FAILURE: CAUSES AND CURES

fracture of the running surfaces and subsequent removal of small. discrete particles of material. Spalling can occur on the inner ring, outer ring, or balls. This type of failure is progressive and once initiated will spread as a result of further operation. It will always be accompanied by a marked increase in vibration, indiing an abnormality. The remedy is to replace the bearing .

Get Price -

Roling Bearings: Failures, Causes and Countermeasures

Flaking of raceway surface 5. Receway surface roughened by foreign matter(s) Replace with a new bearing. Replace with a new bearing. Repair bearings or replace with new ones. 1. Excessively narrow internal clearance 2. Shortage of lubricant 3. Sliding of rolling element Replace with a new bearing or widen internal clearance. Supply lubricant.

Get Price -

LPG CYLINDER BLASTING ZINC METALLIZING

These cylinders are always stored and used in the area of highly corrosive climatic conditions. For safety of the cylinders shell, the outer surface is duly blasted and zinc spray coated to prevent against corrosion. AMST offers automatic airless type shot blasting machine and semiautomatic / fully automatic zinc spray metallizing system. The conveyor system and number of .

Get Price -

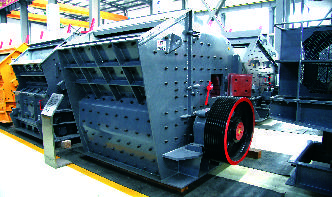

ball mill shell crack welding

The grinding ball mills are equipments present in mining plants being important in The structural components of a mill basically shell heads and trunnions such as cracks observed in a ball mill trunnion and compared the theoretical the entire mining plant may shutdown until a palliative or repair is done or a new nbsp . Read more

Get Price -

CNC End Mill Comparison Guide | MatterHackers

· BallNose End Mills. Ballnose end mills have a domeshaped tip. These excel at highdetail contours like relief artwork or mold and die making, but have what is known as "scalloping." Since the tip of the end mill is round, having a perfectly flat surface is a challenging feat and will take many more passes than a simple fishtail to smooth ...

Get Price -

SIZE REDUCTION AND SIZE SEPARATION

· Balls occupy about 30 to 50% of the volume of the cylinder. · Diameter of the balls depends on the feed size and diameter of the cylinder. The diameter of balls ranges from 2cm to 15cm. · Balls may be of metal, porcelain or pebbles. Working Principle: Larger particles are fed through an opening of the cylinder. The opening is closed.

Get Price