-

Silica Mining | Processing Equipment | Flow Chart | Cases

1, crushing process technological process is: the run of mine ore – grizzly – jaw crusher crushing and screening to cone crushing and screening, more paragraphs to roll the crushing and screening – products.

Get Price -

Sand And Gravel Processing

undergo primary crushing at the mine site before being transported to the processing plant. Figure is a flow diagram for industrial sand and gravel processing. The mined rock is transported to the processing site and stockpiled. The material then is crushed. Depending on the degree of cementation, several stages of crushing may be ...

Get Price -

Extracting Gold | HowStuffWorks

To isolate pure gold, mining companies use a complex extraction process. The first step in this process is breaking down large chunks of rock into smaller pieces. At a mill, large machines known as crushers reduce the ore to pieces no larger than road gravel. The gravellike material then enters rotating drums filled with steel balls.

Get Price -

Gold Mining Equipment | Diamond Mining Equipment | DOVE

GOLDROCKMINER ® Semistationary Hard Rock Processing Plants with capacity range of (22,000 Tons/Hour) solids. Each processing plant is designed tailor made according to the ore characteristics and the mineral composition of the ore, and designed for the recovery of gold and other metals production, with no loss.

Get Price -

EXPLORING HPGR TECHNOLOGY FOR HEAP LEACHING OF FRESH ROCK GOLD .

economic recovery from these fresh rock lowgrade gold ores is increasing. EsnaAshari Kellerwessel (1988), Patzelt et al (1996) and Baum (1997) have reported on the liberation benefits of HPGR for gold and copper ores. Microcracking, resulting from the highpressure interparticle comminution process was believed responsible for

Get Price -

The 5 Main Steps in Processing Diamond Ore | Multotec Canada

· Crushing is done in stages to "gently" free the diamonds from the kimberlite rock and produce a target size, usually less than 25 mm, for further processing. You don't want the pieces to be too small, because you don't want to crush the diamonds! 2 Screening Ore is sized using vibrating screens after each crushing stage.

Get Price -

Gold Fields Agnew to decarbonise crushing operations with new .

· Posted by Daniel Gleeson on 6th June 2022 Gold Fields' Agnew mine in Western Australia is continuing to innovate, with its latest technology development involving the installation of a new modular Rock Processing Solutions crushing system that can align with its daytime solar generation capabilities on site.

Get Price -

Gold processing 101

· Stages 1 and 2: bashing and mashing Traditionally, the process selection choice was between a conventional, welltried, threestage crushing circuit followed by ball milling, or singlestage crushing followed by a semiautogenous (SAG) mill and ball mill.

Get Price -

Gangue crushing processing Mining and Rock .

Coal gangue is a solid waste in coal mining and coal washing process. It is a black and gray rock which is harder than coal with lower carbon content from the process associated with coal seam. It includes waste rock in tunneling process, mining process from the roof, floor and mezzanine in mine and coal gangue singled out in washing process.

Get Price -

Lithium Mining | Processing Equipment | Flow Chart | Cases

What is Lithium. Lithium is an element valuable for the production of glass, aluminum products, and batteries. It is mined from ores of petalite (LiAl (Si2O 5) 2, lepidolite K (Li,Al) 3 (Al,Si,Rb) 4 O 10 (F,OH) 2, spodumene LiAl (SiO 3) 2 and also subsurface brines. Australia and Chile are the world's largest producers of lithium.

Get Price -

Gold Mining Equipment | Hard Rock Gold | Crushing Plant | DOVE

HARD ROCK GOLD PLANT DOVE Equipment Machinery Co., Ltd. designed and supplied customized Hard Rock Gold Processing Plant to the Democratic Republic of Laos. The plant includes complete crushing and grinding lines, processing line for the recovery of gold and flotation circuit. The capacity of the complete processing plant is 100 TPH.

Get Price -

SMALL SCALE MINERAL PROCESSING EQUIPMENT

Small scale mining equipment is available from renown engineers and suppliers, Appropriate Process Technologies (APT). APT's small scale mining equipment is simple to use, efficient and effective. Options are available for the recovery of gold, tin, chrome, tantalite and more.

Get Price -

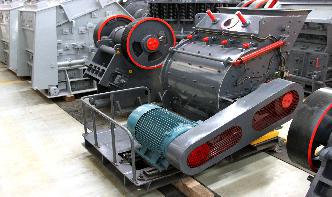

80tph, 120tph Hard rock medium scale rock crushing plant by

Rock Crushing plant with production capacity from 80120 TPH is suitable for small scale production line. SBM Machinery has designed jaw cone crushing plant, jaw impactor crushing plant for hard, medium hard minerals. According to the clients' demands, dust cher, VSI crusher will be equipped.

Get Price -

GS5000 Gold Stryker Gold Ore Impact Flail Processing Rock Quartz Crush ...

Our Gold Stryker ® GS 5000HV is a extreme duty high quality made here in the USA flail impact gold mill that can process and crush up to 5 tons of ( inch) rock in a day, all the way down to #300 mesh through the mill to release the gold. Perfect for the small gold mining operation.

Get Price -

Ultimate Guide of Gold Heap Leaching Process

· 1. Operation of Gold Heap Leaching Process. The Simple Operation of Gold heap leaching process is following: To crush lowgrade gold mines to a certain particle size (or granulation); Pile them on a leakproof bottom pad paved with asphalt, concrete or plastic materials, etc; Spray lowconcentration cyanide, alkaline solution, nontoxic solvent ...

Get Price -

process of crushing rock ballast

The Process Of Crushing Rock Ballast Kenya Xipl double road ballast crusher manufacturer in china offers types ofGood quality track ballast is made of crushed natural rock with particles between Live Chat International Ballast Rock Quarry Henan Mining... Know More. how to crush rocks for ballast ...

Get Price