-

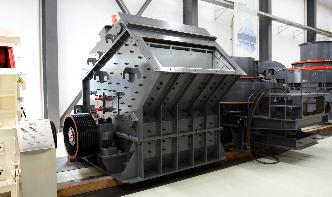

Working Principle of 4 Commonly Used Crushers | miningpedia

· Jaw crushers are widely used in mining, smelting, building materials industry, highways, railways, water conservancy and chemical industries and many other sectors, crushing various materials with compressive strength within 320 MPa.. Working Principle. Jaw crusher mainly consists of a frame, an eccentric shaft, a large pulley, a flywheel, a movable .

Get Price -

Crusher, Crushing, Types of Crusher, Crushing Equipment

Hammer crusher is a kind of equipment with high production capacity, large reduction ratio and high crushing efficiency Spring Cone Crusher Low power consumption and high production efficiency Hydraulic Cone Crusher Hydraulic cone crusher is a kind of crushing equipment

Get Price -

3 Types of Crushers

Gyratory crushers are mostly restricted for primary crushing purposes, but they see some usage for secondary crushing as well. It consists of an oscillating shaft, which presses material between a crushing cavity. The lines around the chambers compress, pressing down on the content being pressed down. There's less damage to the liners in this process as the particles being .

Get Price -

type of crushers | spice crusher bowl

Coal crusher, also known as double stage crusher, is a highly efficient crushing equipment. It is a new type of equipment developed for the coal industry, and it mainly crushes high moisture coal. Besides, it is mainly used to crush coal cinder, slag, shale, coal gangue and other materials. And it can be applied to building material, highway ...

Get Price -

Types Of Crusher Advantages and Disadvantages

· Versatile: These crushers can crush different types of materials with ease, giving the best results. Save Time Money: Along with this, everything involved in buying topquality granite crushers is meant to provide value for the money you spend which will make your business profitable in no time. This is thanks to the reduced costs and increased production .

Get Price -

type of crushers | rock placement company spokane

Cone crushers and gyratory crushers are also compressiontype machines that crush material between a moving piece of steel and a stationary piece. The output is controlled by the setting between the two pieces of steel. Though the chamber is round in shape, the moving piece of steel is not meant to rotate.

Get Price -

Small Mobile Crusher

Features. The crushing ratio is large, crushing power, uniform particle size. Adapt to many types of material. With continuous work, less downtime, low energy consumption, low cost. Compact and reasonable structure, easy to operate. Nonpolluting. High wearresistance materials, long life. Easy maintenance. Motor engine or diesel engine.

Get Price -

which types of metal crushing plant in zimbabwe

Used Crushers Machinery and Equipment. We are one of the largest suppliers of used crushers and crushing equipment for mining and minerals appliions, as well as chemical processing facilities. We deal in all types of crushers including cone, impact, gyratory, jaw, double roll and more. View our inventory and send us your request today. Get Price

Get Price -

4typesofcrushingplant

· Until now the types of crushing plant have become diverse, mainly in the following four egories: Mobile crushing plant Semimobile crushing plant Semistationary crushing plant Stationary crushing plant Let's drive in! Mobile Crushing Plant

Get Price -

7 Types of Stone Crusher and How to Choose the Best?

· Analysis of crushing method of different stone crushers. Crushers can be divided into three egories according to the particle size of feed and products: Coarse crusher: crushing from 1500 ~ 500mm to 350 ~ 100mm; Medium crusher: crushing from 350 ~ 100mm to 100 ~ 40mm; Fine crusher: crushing from 100 ~ 40mm to 30 ~ 10mm.

Get Price -

Construction Working and Maintenance of Crushers for Crushing .

There are two types of impact: gravity impact and dynamic impact. Coal dropped onto a hard surface such as a steel plate is an example of gravity impact. Gravity impact is most often used to separate two materials which are having relatively different friability. For example, in a rotary breaker, separation of the more friable material can be done by screening the material after .

Get Price -

which types of metal crushing plant in zimbabwe

We deal in all types of crushers including cone, impact, gyratory, jaw, double roll and more. View our inventory and send us your request today. Get Price metal used in vertical jaws of stone crusher

Get Price -

types crushers crushing

Types of Rock Crushers Quarry Crushing Equipment. Compression style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Get a quote

Get Price -

3 Types of Crushers

There are two kinds of jaw crushers: single toggle and double toggle. The single toggle jaw crusher uses a Shaft rotation for a compressive action. The double toggle crusher has two shafts toggle plates each. Gyratory crushers

Get Price -

The basics of crushing : Pit Quarry

· The two most common types of crushers are compression crushers and impact crushers. The four factors affecting the crusher type, be it compression or impact, for an aggregate operation are: Type of material (abrasiveness) Hardness of material (friability) Density (toughness) Fragmentation (particle shape) Condition

Get Price -

Samyoung Korea Crusher Plant | Crushers, Sand Making Plant, .

Jaw crusher, cone crusher, horizontal impact crusher, vertical shaft impact crusher, vibrating screen, vibrating feeder and mills are our typical crushing equipments. Jaw Crushers Jaw Crusher is a kind of Stone crusher and jaw crusher is also called Rock crusher. CONE CRUSHERs

Get Price -

What is primary crusher and types of primary crushers

· Primary crushing reduces this runofmine rock to a more manageable size. The different types of primary crushers are: jaw crushers, gyratory crushers, impact crushers, and autogenous crushers. By: SBM Group. Nov. 29, 2011 PRLog Crushing is the first step in converting shot rock into usable products. Essentially, crushing is no more than ...

Get Price -

Types |

· s can also be egorized by their capacity or can size they are able to compress. Most s are made for crushing 12oz cans, as it is the most popular aluminum can size for sodas. 16oz is the second most popular can size that is supported by s. One thing to note, if is intended to compress 16oz sized ...

Get Price -

Crushing Machine

50 TPH. Power. 50hp. Voltage. 415kw. Brand. GECO. We are the leading manufacturer of Stone Crushing Machine and our product is made of good quality. High Performance Carefully designed crushing chamber, Crushing Speed and Throw Results in higher productivity.

Get Price