-

density quarry stone

WHAT ARE THE ENGINEERING AND PHYSICAL PROPERTIES OF STONES, 0183 32 Dressing is easy in stones with lesser strength Hence an engineer should look into sufficient strength rather than high strength while selecting stones for building works 13 Seasoning The stones obtained from quarry contain moisture in the por The strength of the .

Get Price -

Density of Materials | Material Properties

It has an estimated density of x 103 kg/m3. The density of Hassium results from its high atomic weight and from the significant decrease in ionic radii of the elements in the lanthanide series, known as lanthanide and actinide contraction. Density – Pressure and Temperature The density of a material varies with temperature and pressure.

Get Price -

Limestone Quarrying and Processing: A LifeCycle Inventory

Data have been obtained for the quarrying and processing of 570,000 tons and 250,000 tons of limestone, respectively. The average gross energy required to produce one ton of limestone is million BTUs. Table 1 shows the breakdown of this gross energy per ton of limestone product produced.

Get Price -

density of quarry blend stone

Quarry process is also referred to as QP, Dense Grade Aggregate (DGA), Shoulder Stone, Item #4, Crusher Run and DGABC. Aggregates range in size from 3/4" through to a #200 sieve. Quarry process is composed mostly of 3/4 minus crushed stone in a blend of stone dust this is graded enough to produce a low void content at the maximum weight when ...

Get Price -

Travertino: from the block to the tiles – all the processing steps

· Each layer is clearly distinguished from the others, both in terms of colour but also in terms of veining and density. The actual quarrying phase is obtained by cutting the wall by diamond wires and a large diamond chain saw which is used to cut the base of the wall.

Get Price -

Stone, crushed volume to weight conversion

Stone, crushed weighs gram per cubic centimeter or 1 602 kilogram per cubic meter, density of stone, crushed is equal to 1 602 kg/m³. In Imperial or US customary measurement system, the density is equal to pound per cubic foot .

Get Price -

quarry shot stone in place density

· quarry shot stone in place density dangling feet in water video marble powder manufacturing machine manufacturer of ... Rock Blasting Services » Quarry Blasting Low density,, stone processing plant slag .

Get Price -

density of quarry processed stone

Quarry Groupe Bellemare . Quarry We mine several quarries in the Mauricie region and are able to provide a complete range of products MG 20 MTQ 0 3 4 crushed stone MG 20B 0 3 4 NC crushed stone MG 56 MTQ 0 2 1 2 crushed stone 0 2 5 mm 0 1 8 stone screening dust 0 5 mm 0 1 4 stone screening dust Clean Stone 2 5 5 1 4 1 8 nbsp . See More

Get Price -

Mass, Weight, Density or Specific Gravity of Bulk Materials

As specific gravity is just a comparison, it can be applied across any units. The density of pure water is also lbs/ (pounds per cubic foot) and if we know that ammonium nitrate has a sg of then we can calculate that its density is x = lbs/ Note, kg/ divided by = lbs/

Get Price -

Slate Quarrying and Processing: A LifeCycle Inventory

Data have been obtained for the quarrying and processing of 540,000 ft3 and 260,000 ft3 of slate, respectively. The average gross energy required to extract and fabrie 1 ft3 of slate is 19,000 MJ. Table 1 shows the breakdown of this gross energy per cubic foot (ft3) of .

Get Price -

Optimized extraction of dimension stone blocks | SpringerLink

· The average joint density in the examined rock mass is as high as joints per m³ and thus, according to Sousa ( 2010 ), too high for the exploitation of large volume blocks. For this reason, it is highly important to loe areas with lower joint .

Get Price -

A Study on Utilization Aspects of Stone Chips as an Aggregate ...

The concrete having density of 2300 3kg/m to 2600 kg/m3is produced. CLASSIFICATION NATURAL BASALTICAGGREGATE BASED ON WEIGHT Normal Weight Aggregates Light Weight Aggregates Heavy Weight Aggregates TABLE 2 CLASSIFICATION OF AGGREGATESBASED ON WEIGHT CHARACTERISTICS OF AGGREGATES (FACTORS .

Get Price -

Building stone quarries: resource evaluation by block modelling .

· The amount of the quarrying (160 Mt) and processing waste ( Mt) of the quarries reaches more than 71%, leaving less than 29% for the final products in the year 2018 (Montani 2019) (Fig. 1 ).

Get Price -

Paver Base: Your Ultimate Guide

· It is made up of finely crushed stone, which has been fed through a screened feeder to ensure size uniformity of the finished product. With binding characteristics that support excellent compaction density, QP is typically comprised of limestone, gneiss, trap rock or granite. Recycled concrete aggregate (RCA) is an excellent alternative to QP.

Get Price -

Quarry ByProducts

· It is estimated that at least 159 million metric tons (175 million tons) of quarry byproducts are being generated each year, mostly from crushed stone production operations. As much as billion metric tons (4 billion tons) of quarry byproducts have probably accumulated. (3) CURRENT MANAGEMENT OPTIONS Recycling

Get Price -

Quarrying of stones

The process of raking out stones from natural rock beds is known as the quarrying. The term quarry is used to indie the exposed surface of natural rocks. The difference between a mine and a quarry should be noted. In case of a mine, the operations are carried out under the ground at great depth. In case of quarry, the operations are carried ...

Get Price -

density of quarry stone

Density Of Quarry Processed Stone. Get Price 20 mm crusher run limestone bulk density 20 mm crusher run limestone bulk density density of quarry dust The bulk density of ROBO sand or crusher gravel and granite while sizes involved are 20 and 28 Oct 25th 1 6 mm crushed stone . 20mm stone quarry plant density of crusher stone dust ...

Get Price -

Density of Common Building Materials per Cubic Foot

· These values for density of some common building materials were collected from sites across the Internet and are generally in agreement with multiple sites. ... Crushed Stone: 100 lb/ft 3: 1,600 kg/m 3: Earth, loam dry excavated: 90 lb/ft 3: 1,440 kg/m 3: Earth, packed: 95 lb/ft 3: 1,520 kg/m 3: Glass, window: 161 lb/ft 3: 2580 kg/m ...

Get Price -

Crushed Stone Vs. Gravel

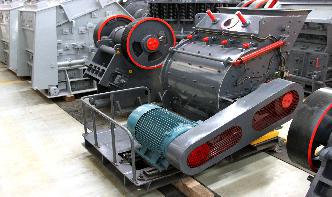

· Crushed stone ranges in size from fine stone dust (screenings) to larger and heavier stones. Gravel comes in various sizes that are larger than 2 mm in diameter, starting from about a ¼ inch, and going up to 2 inches or more. Where Does Crushed Stone Come From? Most of the crushed stone is produced in quarries and is crushed by a machine.

Get Price -

Crushed stone

Crushed stone. 20 mm ( in) crushed stone, used for construction aggregate and landscape appliions. Crushed stone or angular rock is a form of construction aggregate, typically produced by mining a suitable rock deposit and breaking the removed rock down to the desired size using crushers. It is distinct from naturally occurring gravel ...

Get Price -

Building stone quarries: resource evaluation by block modelling .

· The production of building stones shown an exponential growth in last decades as consequences of the demand and developments in the extraction and processing techniques. From the several conditioning factors affecting this industry, the geological constrains at quarry scale stands out as one of most important. Globalization and increasing competition in the .

Get Price -

density of quarry blend stone

· Stone, crushed weighs gram per cubic centimeter or 1 602 kilogram per cubic meter, density of stone, crushed is equal to 1 602 kg/m³. In Imperial or US customary measurement system, the density is equal to pound per cubic foot [lb/ft³], or ounce per cubic inch [oz/inch³] . . Read More

Get Price -

The Granite Processing Life Cycle

· The quarry process is inclusive of activities like drilling the holes along the edges of the granite bench, cutting the stone in the despite using diamondwire saws, and dividing the stone using hydraulic machinery. After the bench is detached from the main deposit, hydraulic cranes are used to take out the granite bench from the deposit.

Get Price