-

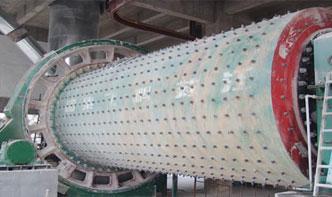

Cost Of Grinding By Wet Vs Dry In Iron Ore

Difference between dry and wet iron ore Henan Mining. Grinding by wet vs dry in iron ore vibrating sieve separator. Size Distributions and Energy Consumption in Wet and Dry Grinding where ED and Ew are respectively energy for wet and dry grinding k is the size may be regarded as wet milling with a fluid of l. View Details Send Enquiry

Get Price -

mineral wet grinding vs dry grinding

T00:08:00+00:00 Dry Grinding VS Wet Grinding Mineral Processing Metallurgy. A slight difference of condition between the two cases, however, is that with dry milling the fluid (air) fills the whole of the mill shell not occupied

Get Price -

iron ore wet processing and beneficiation plant

iron ore wet plant . iron ore wet processing and crushing plant Ore plant. · iron ore wet processing and crushing plant Iron Ore Processing PlantMineral Beneficiation MachineGold Gold Mining Equipment Gold Quarry Machine Manufacturer Products are exported to over 20 countries around the world,such as Malaysia, South Africa, Nigeria, Iron Ore

Get Price -

Mineral Processing

· The mineral beneficiation involves separation of gangue minerals from ore. It has three steps Liberation, Separation, Concentration. 1) Liberation of valuable mineral by size reduction. 2) Separation of coarse and fine particles. 3) Concentration to separate the gangue minerals to increase the metal grade.

Get Price -

Mineral Ore Beneficiation | Mining, Crushing, Grinding, Beneficiation

· Production details: After the beneficiation, the grade of iron concentrate can up to more than 64%, SiO2 content can be controlled lower than 6%, and the content of harmful elements, such as S and P, can meet the standards set by .

Get Price -

wet grinding iron ore

iron ore wet grinding system. · Processes for Beneficiation of Iron Ores – IspatGuru. Mar 28 2015 · Beneficiation begins with the crushing and grinding along with wet or dry classifiion of extracted ores in preparation for further activities for the enhancement of iron content of the ores Crushing and grinding is a multi staged process and may use dry or wet .

Get Price -

The Beneficiation Method of Rare Earth Minerals

· Dry Drum Magnetic separator is one of the most widely used and versatile machines in mineral processing. Mineral technologies electrostatic separators suitable for manganese ore, magnetite, pyrrhotite, roasting ore, ilmenite, hematite, and other materials below 50mm granularity, dry magnetic separator, and wet drum magnetic separator.

Get Price -

beneficiation plant vs wet grinding

Mineral processing Wikipedia. In the field of extractive metallurgy mineral processing also known as ore dressing is the mineral processing plant Crushing is a dry process whereas grinding is generally performed wet and hence is more energy intensive In this plant zircon rutile and ilmenite are separated from the silica gangue In this plant the

Get Price -

Beneficiation Plant Vs Wet Grinding

· Jul 31, 2017· Home / Products / 15a ore mineral processing grinding of, Professional Ore Process Kaolin Dry And Wet Iron Sand Beneficiation Plant, beneficiation plant vs wet grinding gujaratgenomicsin. Beneficiation Plant Vs Wet Grinding beneficiation plant fly ash concrete grinding mill of tailing pond for, dry and wet grinding in ...

Get Price -

Mineral beneficiation and ore dressing

The typical stages of mineral beneficiation are as follows: Communiion Communiion is made on dry material or slurries to reduce their size. Communiion involves either the crushing or grinding of ores. The crushing process is by the runofmine, whereas the ground, the second step after crushing, is on dry material.

Get Price -

Grinding In Mineral Processing

Mineral processing milling introduction milling, sometimes also known as fine grinding, pulverising or comminution, is the process of reducing materials toowder of fine or very fine size. it is distinct from crushing or granulation, which involves size reduction toock, pebble or grain size. milling is used to produceariety. Live Chat

Get Price -

Lecture Mineral Beneficiation

down to about 25mm. In grinding finer size is produced. Grinding or milling is an important size reduction method. In grinding force is applied by a medium which could either balls or rods .Both dry and wet grinding is done Wet grinding has the following characteristics. •

Get Price -

coal beneficiation wet process introduce

Introduction to Mineral Processing ByIsh Grewal, Introduction ... coal and clays. ... where the beneficiation process is applied directly on runofmine ores .... Grinding is carried out as a wet process with water content between 50 – 70% by weight. More details ... Dry beneficiation of coal with an air dense medium.

Get Price -

Different types of separation methods for minerals

Mineral processing is the first step for ore once it leaves the mine. The process involves ore preparation, milling, and ore dressing, commonly known as beneficiation. Beneficiation mechanically separates the grains of ore minerals from the gangue (low value) minerals that surround them in order to produce a concentrate made up of useful minerals.

Get Price -

Beneficiation process and separation method,crushing grinding .

· Grinding: Mainly on grinding and impact. Grind the crushed product to a particle size of 10300μm. The grinded particle size is based on useful minerals The particle size of the immersion dye in the ore of the beneficiation machinery and .

Get Price -

Summary of dry and wet processes for quartz sand

· Wet process: Wet beneficiation mainly uses mechanical scrubbing combined with magnetic separation, flotation, acid leaching and other processes to remove impurities, especially iron impurities, in...

Get Price