-

PQ University Lesson 8 Screening : Pit Quarry

· Alternatively, on a 20degree incline and at 70 to 75 ft. per minute travel rate, an incline screen will deliver up to 25 percent more capacity than a linearstroke horizontal machine. Unlike the latter, the circular motion of an incline screen results in .

Get Price -

flow direction of panels on vibrating screen

In conclusion, the vibrating screen of translationswing composite motion is determined by the vibration frequency, amplitude, vibrating direction angle, swinging frequency, and swinging angle. A 3D model was set up to simulate particle flow on a vibrated inclined screen, the initial parameters were shown in Fig. 4, and the angle of screen ...

Get Price -

Vibrating Screens, Vibrating Grizzlys, Vibrating Feeders

Syntron® Vibra Drive Units are used in many different industries to provide directional vibratory conveying movement to a track, trough or any responsive surface. They are designed for use with package machines or special process equipment requiring a metered flow of bulk materials or parts. Pneumatic Vibrators:

Get Price -

BALBOA Control Panels User Guide

· Priming the Pumps. As soon as the above display appears on the panel, push the "Jets" button once to start Pump 1 in lowspeed and then again to switch to highspeed. Also, push the "Jets 2" or "Aux" button, if you have a 2nd pump, to turn it on. The pumps will now be running in highspeed to facilitate priming.

Get Price -

FOOD BEVERAGE SCREENS | Sales

Uses for the most common types are as listed below: Flat Screen Panels Filtration, brewing (via lauter tun screens), separation, sizing, fluid bed drying, washing, vibratory screening and more Sieve Bend Panels Processing sugar and corn (for corn starch), sizing and washing, and more Cylinders and HalfCylinders

Get Price -

flow direction of the panels on a vibrating screen

Feb 16, 2020 Working Principle: The two motor axes of the linear vibrating screen have an angle of inclination in the vertical direction relative to the screen panel. Under the combined force of the exciting force and the self gravity of the material, the material is thrown on the screen surface to jump or move forward in a straight line.

Get Price -

flow direction of the panels on a vibrating screen

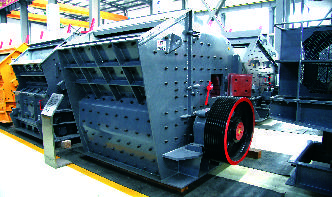

flow direction of the panels on a vibrating screen T03:04:24+00:00. Wheel Sand Washing Machine. TSW Series Vibrating Feeder. CI5X Series Impact Crushers. Dry Magnetic Separator. Three combinations mobile crushing plant. ... 5X Vibrating Screen. GF series feeder. B Series VSI Crusher. Ball Mill. High Frequency Screen.

Get Price -

ConstructionWorkingandMaintenanceofVibratorsandVibratingScreens .

A vibrating screen is vibrated in order to throw particles off the screening surface so that they can again be presented to the screen, and to convey the particles along the screen. Vibration also lifts the large particles out of the holes (If the large particles are not lifted out, it will plug the screen).

Get Price -

FlipFlow Vibrating Screen

FlipFlow Vibrating Screen adopts the principle of double mass near resonance, so that the floating screen frame has a large amplitude, and the screen surface can deliver the material with an acceleration of up to 50 G. It is widely used in dry screening of medium and finegrained, wet, sticky and other difficult to screen materials.

Get Price -

What's the Vibrating Screen Working Principle?

The working principle of the circular vibrating screen is that after the screen machine is started, the screen machine vibrator drives the vibrating screen box to make a directional jumping motion. During this time, the material smaller than the screen surface aperture falls to the lower layer through the screen holes and bec Continue Reading

Get Price -

Vibrating Screen Panels

HUATAO GROUP SCREENS ADD : ZHONGHUA NORTH STREET, SHIJIAZHUANG 050000 CHINA. TEL : +86 0311 EMAIL :maple Web: ...

Get Price -

Basics of Orifice Plates

Basics of Orifice Plates. by Editorial Staff. Of all the pressurebased flow elements in existence, the most common is the orifice plate. This is simply a metal plate with a hole in the middle for fluid to flow through. Orifice plates are typically sandwiched between two flanges of a pipe joint, allowing for easy installation and removal:

Get Price -

RAINSCREEN PANEL DESIGN GUIDE

· place loads on the panels, must be reviewed by the panel designer. Usually a lead or plastic insert is used for attachment. Any holes drilled into panels must be cored with a nonhammer type drill. Core bits are available as small as 3/8" (). Hammer type drills will spall the back of the panel and could affect the integrity of the panel ...

Get Price -

Study of the dynamics and analysis of the effect of the position of .

· When the vibration motor is moving in the negative direction of the horizontal direction the change rule is opposite to the case of positive direction; if the vibration motor is meters away from the focus of screen, the vertical vibration amplitude of the points on the sieve reaches the maximum value.

Get Price -

flow direction of the panels on a vibrating screen

Noise and Vibration Reduction of a Vibrating Screen performed, the standard steel screen panels were replaced with urethane screen panels After examining the test data, it was determined that the coal/water flow was a secondary noise source and the urethane siev would, therefore, not have an impact on sound levels for this screen Steel coil springs vs rubber .

Get Price -

Polyurethane FlipFlow Vibrating Screens

Characteristic: . FlipFlow Vibrating Screens remove fines out of wet, sticky or generally difficult to handle materials. Materials processed using a FlipFlow Vibrating Screen typically cannot be screened using other technologies, such as rotary screens, conventional vibrating screens, etc. Appliions where the screen might be used include municipal solid waste, tire recycling, .

Get Price -

181 Process Flow Diagram (PFD) Symbols for Engineers

Process Flow Diagram Equipment Symbols. Flow chart symbols use different shapes to represent different components, such as equipment, valves, instruments, and piping flow. There is a standardized set of flowchart symbols. Process Flow Diagram equipment symbols include centrifuges and heat exchangers.

Get Price -

HEAVY DUTY INCLINED VIBRATING SCREENS

HEAVY DUTY INCLINED VIBRATING SCREENS The Standard of Excellence Since 1912. Bulletin No. 300D. ... Screen Panels and Tension Plates Adjustable Panel Heavy HBeam Stationary Base Pickup Bracket and ... in the same direction as before, leans back toward the feed end of the machine.

Get Price