-

Ball Mill Balls For Ore

Ball Mill An Overview Sciencedirect Topics . ball mills tumble iron or steel balls with the ore. the balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. the feed to ball mills is typically vol.% ore and 25% steel. the ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol and impact wear .

Get Price -

free milling gold ores

processing free mill gold ore Establishing thE ProcEss MinEralogy of gold orEs . 2004 Establishing thE ProcEss MinEralogy of gold orEs JoE Zhou, brucE Jago and chris Martin –– sgs lakEfiEld rEsEarch liMitEd abstract From the perspective of metallurgical processing, gold ores can be classified into freemilling and refractory ores.

Get Price -

Ball Mill Linings | Multotec

Our design comprises a steel core structure and is covered with a highdensity rubber lining. The thickness of the rubber lining is dependent on appliion. Our Pulp Lifters are designed to ensure the correct volumetric flow of pulp while preventing carryback. Central Cones and Goosenecks

Get Price -

Mercuryfree, smallscale artisanal gold mining in Mozambique ...

The extraction of gold from ore differs very little from one arti sanalandsmallscaleminingsitetoanotherintheManicaprovince. Ore is crushed using a mortar and pestle, and the resulting rock is placed in a ball mill constructed from a discarded metal gas tank containing stainless steel ball bearings of various sizes.

Get Price -

Available online at ScienceDirect

Grinding is accomplished by abrasion and impact of the ore with moving media such as rods (rod mills), balls (ball mills), or pebbles (sized ore in AG SAG mills). These vary in size according the size of particle being processed.

Get Price -

[PDF] An Overview Of the SmAllScAle teStS AvAilAble tO .

The hardness of ore samples is measured through grindability testing. Several grindability tests, at various scales, have been developed over the years for different appliions, from conventional circuit to autogenous grinding, and they all have strengths and weaknesses. The traditional approach to AG or SAG mill design, based on the testing of a large bulk sample in .

Get Price -

Ball Milling Design

Ball Mill Design Handbook. may 17, 2019 pdf design and fabriion of mini ball mill part 2. http com assets ballmill operatingmanual pdf. ball mill design handbook pdf kaser vtngcf org. circulating load calculation formula. ball mill design power calculation. mechanical milling a top down approach for the synthesis of. chapter 5 ...

Get Price -

Ball Mill Gold Ores Dimension

Jan 01 In this case as the work index and ball mill conditions are unknown we refer to the Appendix and find that the work index of a gold ore is typically 1483 kWht Step 2 To determine the maximum ball size to be charged to grind the ore Equation 716 may be applied as all the relevant parameters are now known.

Get Price -

Ball Mill

A ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shell.

Get Price -

Gold processing 101

· At current gold prices this is worth about US600. Both smelter treatment charges and oxidation or bioleach costs are at least 200/t of concentrate and payables/recovery in the 90% range, so a minimum GSR for effective downstream processing is around

Get Price -

For personal use only

• planned SAG mill circuit to be replaced by three stage crushing and Ball mill; • AARL elution circuit to be replaced by Pressure Zadra plant. • Start up Capital costs reduced to US including contingency of US • Updated Project Financial Model using a gold price of US1,550 demonstrates that the Borborema project will:

Get Price -

How Gold Is Mined | Gold Mining Process | World Gold Council

Gold mine development is the next stage of the gold mining process. It involves the planning and construction of the mine and associated infrastructure. Mining companies must obtain appropriate permits and licenses before they can begin construction. This will generally take several years, although this varies greatly depending on loion.

Get Price -

ball mill design calculations

The ball mill work index laboratory test is conducted by grinding an ore sample prepared to 100 passing 336 mm 6 mesh to product size in the range of 45150 181 m 325100 mesh, thus determining the ball mill work index Wi B or BWi The work index calculations across a narrow size range are conducted using the appropriate laboratory work ....

Get Price -

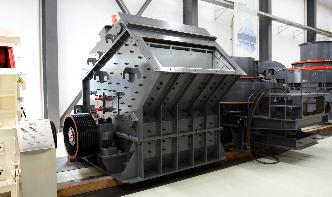

ball mill jaw crusher circuit

ore impact crushing circuit Mobile Crushers all over the · ore impact crushing circuit heavy industry is specialized in the design manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant jaw crusher cone crusher impact crusher milling equipment ball mill vibrating feeders screens and .

Get Price -

how to maintain ball mill gold ore machine in india bing

MEI Blog Where are SAG mills going Barry A Wills · If you grind the gold quartz ore for liberation the gold particles in the microwave hypothetical mill the specific energy consumption will be 0 08kw t Size of valuable minerals in the ore is reduced every 10 years If in 80 s ore more milled to 80 74micron in 90 s 44micron in 0 s 20micron now grinding limit is reduced to 2micron

Get Price -

THE EFFECT OF BALL MILL OPERATING PARAMETERS ON MINERAL LIBERATION

Mill speed, mill charge, ball size, and wet grinding are the parameters which have been selected for the present study. It is hoped that the analysis of the data acquired will allow insight as to which parameters will require a functional form if they were to be integrated into

Get Price -

mill design for ball mill ores

Procedures For Ore Mill Ball Mill Design. 12/08/2019 Procedures For Ore Mill Ball Mill Design. Ball mills . A ball mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be rotation is usually between 4 to 20 revolutions per minute, depending upon the diameter of the mill.

Get Price -

STARTLING EFFECT OF BALL SCATS REMOVAL ON SAG MILL .

Plant Manager Process Design, AngloGold Limited PO Box 62117, Marshalltown, 2107, Johannesburg, South Africa email: ismit ABSTRACT An increase of over 10% in mill throughput was...

Get Price