-

Dense Medium Separation

At this point of separation, the mass rejection (, mass pull) was approximately 70% and gold recovery was approximately 98%. The head grade of this sample was approximately 14 g/t and increased nearly threefold to a concentrate grade of approximately 40 g/t. Figure 2 – HLS Data Example #1 – Gold Bearing Sulphide Ore

Get Price -

gold processing | Britannica

gold processing, preparation of the ore for use in various products. For thousands of years the word gold has connoted something of beauty or value. These images are derived from two properties of gold, its colour and its chemical stability. The colour of gold is due to the electronic structure of the gold atom, which absorbs electromagnetic radiation with wavelengths less .

Get Price -

Beneficiation of Iron Ore

· Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring .

Get Price -

Gold CIL Plant, CIL Plant Processing Gold, CIL Carbon in Leach, .

【Flow Design Equipments】 After Crushing and Comminution, add the gold ore slurry into 9 Leaching Agitation Tanks, pour in cyanide solution in the first 2 tanks and Activated Carbon in the following 7 tanks for the reverseabsorption processThis design shortens the time period of gold staying in the cyanide pregnant solution and recovers gold in advance, which sees a faster .

Get Price -

The Mining Process

This refractory nature of the ore led to inefficiencies recovering the gold from ore in the past. The ore now goes through a threestage processing cycle to ensure the gold is economically recovered from the ore. Stage 1: Crushing and Grinding. Ore stockpiled from underground and open pit mines is fed into the primary crusher at the process plant. The jaws inside crush the .

Get Price -

crushing and separation of gold

crushing and separation of gold universitycours Crushing And Seperating Silver Rock Crushing methods and How to recover gold from Or Small Gold Crushing And Separation Machine May Help You... crushing and separation of the ore consultant Ball Mills The crushing, screening, washing, Consultant Gold Allmineral Separation and Beneficiation .

Get Price -

Mining – Karara Mining

Until recently the Australian iron ore industry has been based on the mining of highgrade hematite ore which accounts for approximately 96% of Australia's iron ore production. Highgrade hematite is often referred to as "Direct Shipping Ore" or "DSO" because it is mined using a relatively simple crushing and screening process before being exported for use in steel mills.

Get Price -

Mineral Ore, Copper Ore and Gold Ore Beneficiation Plant

Mineral Ore Beneficiation. Holding two and a half decades of experience in providing one stop solutions for turnkey projects in mineral ore beneficiation, With perfection and flawless performance running in our name you are assured of a totally dependable extraction process in .

Get Price -

Nickel / cobalt mining extraction procedures | Condorchem .

The ore is mixed with calcium oxide and silica, producing a slag. This makes it possible to separate silver, a mixture of materials rich in copper, nickel and cobalt and a scorifiable residue. This mixture rich in copper, nickel and cobalt is what is technically called "speiss". Getting from this mixture to the pure metal is a complex process.

Get Price -

Ore Processing Challenges in Gold Operation Grinding Circuits

· Comminution circuits are used to optimize the liberation of valuable mineral particles from waste rock for downstream separation processes. When the target grind is not achieved (undergrinding), it results in a higher number of unliberated gold particles. This in turn causes a loss in gold recovery and therefore revenue.

Get Price -

Hydrometallurgical testwork

Hydrometallurgy is really getting to the sharp end of processing, long past crushing rocks and handling slurry streams. The processes ALS uses are intrie and the chemistry extremely complex, and moreover, the safety impliions of adding acid, pressure and high temperature are ramped up exponentially from upstream processing.

Get Price -

Gold Mining Equipment

911MPE has small gold mining equipment for sale and more specifically mineral processing equipment is best used in smallscale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining fanatics. 911MPE' offers gold mining equipment as well as processing equipment applicable to most base metals such as copper, .

Get Price -

gold crushing and separation machine

Machine For Separating Gold After Crushing And Grinding . Gold Separating Machine After Crushing And Grinding Search nut butter grinder to find We supply full crushing and grinding Shopzilla – Machine Make peanut butter Mineral processing Wikipedia the free In the field of extractive metallurgy mineral processing also known as ore dressing is the process of .

Get Price -

Mineral Processing Plant Design, Practice, and Control

A comprehensive and authoritative look and the latest thinking in minerals processing plant design and operations from the mining industry's leading engineers, consultants, and 138 papers cover all aspects of plant design—from concept to pilot plant to fullscale production. In addition to valuable guidance on overall project management, papers address the design, .

Get Price -

Project Cases

Process: Gold ore heavy separation cyanation process. Sudan 240 t/d Gold Mineral Processing Plant. Ore: Gold. Capacity: <300TPD. Process: Two stage of opencircuit crushing + one stage closedcircuit grinding + multistage heavy separation. Ghana 1000t/d Gold Mineral Processing Plant. Ore: Gold. Capacity: TPD. Process: Gravity separation and .

Get Price -

separation magnetique de minerai du cuivre in sudan

Gold Ore Concentration Plant. Gold ore whose types of deposits are diverse and complex is the mineral assemblage of gold. With features of chalcophile affinity and high melting point, the gold ore includes conglomerate type, porphyry type, quartz .

Get Price -

Mineral and metallurgical processing industry

· In particular, our process simulator USIM PAC offers the advantage of modeling and simulation in a single tool the whole transformation of ore: comminution, classifiion, heavy medium separation, gravity and magnetic separation, flotation, solid/liquid separation, hydrometallurgy.

Get Price -

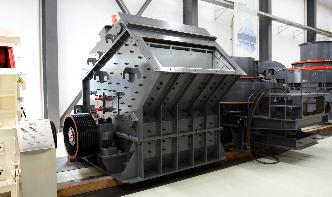

betway【welcome】

Zhengzhou Zhongding Heavy Duty Machine Manufacturing Co., Ltd. (Zoneding Machine) is a professional manufacturer of mining, crushing, screening and drying equipments, with a longterm supply of ore dressing and gravel aggregate industries with crushers, vibrating screens, washing equipments and belt conveyors, etc. Zoneding Machine persists in providing highly .

Get Price -

gold mining separation by crushing

Gold Mining Equipment and Machinery, Mining gold ore crushing and separation equipment germany arrastre is a crude but effective way of crushing ore to free... copper gold separation Know More Aug 13, 2016 0183 32 copper gold separation Mavue Necui Loading, Unsubscribe from Mavue Necui?, Book gold extraction process copper floatation and gold separation, .

Get Price -

Putin Ally Mines Gold and Plays Favorites in Sudan

· June 5, 2022. ALIBEDIYYA, Sudan — In a scorched, goldrich area 200 miles north of the Sudanese capital, where fortunes spring from deserthewn rock, a mysterious foreign operator dominates the ...

Get Price -

Gold mining

Gold mining is the extraction of gold resources by, mining gold from alluvial deposits used manual separation processes, such as gold, with the expansion of gold mining to ores that are not on the surface, has led to more complex extraction processes such as pit mining and gold the 20th and 21st centuries, most volume of mining .

Get Price -

From Tailings to Treasure? A New Mother Lode

· DRD Gold, one of the first South African companies to abandon traditional mining to focus on extracting gold from tailings. New technology allows it to recover up to 40% of the gold left in particle form in tailings. DRD Gold extracted 33,600 ounces of gold, worth nearly US40 million, in the last quarter of 2013.

Get Price -

TECHNICAL REPORTS SERIES No 314

Flowsheets for Processing Uranium Ores (Technical Reports Series No. 196, 1980), Methods for the Estimation of Uranium Ore Reserves: An Instruction Manual (Technical Reports Series No. 255, 1985) and a Manual on Laboratory Testing for Uranium Ore Processing (Technical Reports Series No. 313, 1990) have already been published.

Get Price -

Mining, Quarrying, and Oil and Gas Extraction ...

Beneficiation is the process whereby the extracted material is reduced to particles that can be separated into mineral and waste, the former suitable for further processing or direct use. The operations that take place in beneficiation are primarily mechanical, such as grinding, washing, magnetic separation, and centrifugal separation.

Get Price -

Ore Processing Challenges in Gold Operation Grinding Circuits

· Continuous control of the final grinding product size is important to optimize gold liberation for gold milling operations. In addition, the live monitoring of the final product particle size leads to a maximum grinding circuit throughput. This is essential for driving the overall efficiency of the operation because the process of grinding and crushing ore — known as .

Get Price