-

Grinding Pyrolysis | Renergi Pty Ltd

Renergi's grinding pyrolysis technology can grind and pyrolyse the biomass feedstock even having particle sizes of a few centimetres to produce biochar with a particle size smaller than 100 micron, similar to pulverised coal particles entering a pulverisedfuel combustion system.

Get Price -

The importance of the size of the beads to be selected

The bead size is the most important factor for milling practices. Large beads, bigger than mm, are adequate for grinding micronsize particles into submicronsize ones. Small beads, mm or finer, are applied to grinding or dispersing submicron or nanometersize particles. For dispersing, a large impact is not necessarily required, and ...

Get Price -

grinding smaller than 1 micron

Grinding and Polishing Guide. The abrasive used for each succeeding grinding operation should be one or two grit sizes smaller than that used in the preceding step A satisfactory fine grinding sequence might involve SiC papers with grit sizes of 240 320 400 and 600 grit P280 P400 P800 and P1200 This sequence is used in the traditional approach

Get Price -

How to optimise the wet grinding process for paint production

Mar 20, 2021 · The sieve is the component that prevents the micro beads from exiting the grinding chamber and the grinding paste to pass through. The span of the sieve, its opening or micron size, depends on the size of the beads used in the process. This should be to 3 times smaller than the size of the micro beads. There are 2 types of sieves:

Get Price -

Grinding's Blackest Art

Centerless grinding is suitable for parts with a roundness requirement less than 1μm and when part quantity is suitable. "You can't just do a couple hundred; you need a couple thousand," Warthun said. "I normally explain to customers that we are going to split a micron by a third," Warthun added.

Get Price -

Best coffee grinders 2022 – electric and handheld

24/09/2021 · Coffee beans are poured into an accessible stainless steel bowl (just unscrew the seethrough lid) and a fine grind is achieved in less than 30 seconds. It acts like a mini blender (use it for nuts and spices, too) and we liked the fact .

Get Price -

Micron Ratings

05/09/2022 · 1 Micron = 1 Thouh of a Millimeter. 1 Micron = 39 Millionth of an Inch () Micron = Visible with Magnifiion. 40 Microns = Visible with Magnifiion. 40 to 90 Microns = Diameter of a Human Hair. 5 Micron. Filters with a 5 micron rating remove a large amount of debris from liquid. While there are other, smaller micron ratings ...

Get Price -

Grit Size to Micron Chart

A micron unit is one 10 6 of a meter. A mesh is measured by the number of evenly spaced holes on a screening panel, per square inch. See the table below on how to convert grit into microns. Grit Size to Micron Chart The table above shows the conversion from grit, micron and mesh.

Get Price -

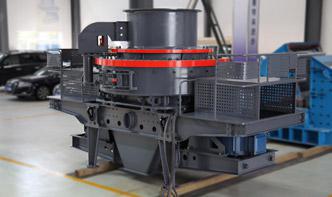

Grinding Less Than Micron

Vsi For Grinding Less Than 1 Mm. Vsi For Grinding Less Than Mm. Vsi For Grinding Less Than 1 Mm. vsi for grinding less than 1 mm grinding less than 1 micron crusher price the 300 optimization to 6 mm and grinding to products less than 20 more 3d analytical mathematical models of random starshape for particles smaller than aboutmm a simple technique is to .

Get Price -

What Are the Advantages of Wet Grinding vs. Dry Grinding?

Sizes smaller than 1 micron in diameter are referred to as the nanometer level. One micron is equal to 1,000 nanometers. Typically, nano sized particles range from 200500nm. The process of achieving particles this small is sometimes called nanonization. In general, dry grinding can reduce particles to singledigit micron sizes.

Get Price -

Wet Grinding vs. Dry Grinding – 2 Amazing Grinding Method

The primary advantage of using a wet grinde r instead of a dry grinder is cost. A typical wet grinder costs around 10,00020,000 compared to an average price tag of 50,000100,000 for a comparable dry grinder. This difference comes largely because wet grinders don't require expensive highspeed motors, bearings, seals, lubriion systems ...

Get Price -

Grinding, Polishing and Figuring

Grinding with abrasives larger than 30 micron is a messy and, depending on your climate, may be better done indoors. Grinding with abrasives larger than 30 microns is messy and, depending on your climate, may be better done outdoors. Grinding the Back Flat ... For abrasives smaller than 120, I prefer aluminum oxide to carborundum because it has ...

Get Price -

Metallographic grinding and polishing insight |

Fine grinding produces a surface with little deformation that can easily be removed during polishing. Because of the drawbacks with grinding papers, alternative fine grinding composite surfaces are available, in order to improve and facilitate fine grinding, A high material removal rate is obtained by using grain sizes of 15, and µm.

Get Price -

Micro Powder Grinding Mill

micro powder grinding mill is mainly used for grinding the material with middle and low hardness, moisture below 6%, and the material should be nonexplosive and nonflammable, such as: calcite, chalk, limestone, dolomite, kaolin, bentonite, HOME PRODUCTS Beneficiation Equipment Grinding Mill Cement Plant Kiln And Dryer Block Machine Pellet Plant

Get Price -

Grinding Mixing

Planetary Mills are offered as a "Fast" Mill for shortened grinding times of frits glazes, and the research models of these units will provide a final particle size of down to less than 1 micron. Various laboratory mixers, from slow speed overhead stirrers to high speed homogenisers are listed below. Jar Mills Jar Mills Floor Mounted Fast Mill

Get Price -

Efficient ultrasonic grinding: a new technology for micronsized .

To burn coal most efficiently and cleanly, much smaller particle sizes are needed than can now be ground economically. This project was performed to demonstrate the technical feasibility of using ultrasonics to enhance grinding below the standard plant grind of 75 microns, and to extrapolate from this laboratory work the ultrasonic energy requirements for production use. .

Get Price -

Micronizer Jet Mill Produces Particles Less Than One Micron

03/02/2014 · Feb 03, 2014 The Micronizer is a jet mill (fluid energy mill) employing compressed air or gas to produce particles less than one micron. Precisely aligned jets create a vortex inside the Micronizer. Material is fed into this vortex along an engineered tangent circle and accelerates at near supersonic speeds.

Get Price -

Coffee Grind Size How It Affects Consistency Flavor

01/12/2017 · The team at Kruve prefer to use microns (μm) to measure grind. Their sieves range from 200 to 1,600 μm. Mark tells me that "microns provide the ultimate reference and control", allowing users to easily share recipes, experiment with different grind sizes, and also calibrate grinders across different shops.

Get Price -

Black Tie Grinder Review: The Ultimate Grinding Experience

The goal of the micron mesh screen is to filter out larger herb particles from smaller more potent particles in the bud known as kief. A good filter keeps out the larger particles and allows pure kief to drop the bottom pollen chamber. We've yet to see an herb grinder that produces more high quality kief than the Black Tie Grinder.

Get Price -

A process mineralogy approach to study the efficiency of .

Dec 03, 2020 · Grinding also occurred for feed particles smaller than d 25 ( microns), but grinding did not have a desirable result for particles larger than microns. Given that the product of open ...

Get Price -

The Significance of Fine Grinding

It is not known exactly what particle fineness was achieved after the many hours of mulling, but it is com monly accepted that the particle size for oilpaint pig ments should be less than 10 microns, and some watercolor pigments are even ground to

Get Price