-

MATERIAL AND ENERGY BALANCE OF PRODUCTION OF GYPSUM FLUIDIZATION PROCESS

16/10/2009 · The reason for this is quite lower temperatures in the production of classical gypsum binders (125 – 180 oC) in relation to frying temperature clinker of cement (1450 oC) and lime ( 1200 oC ...

Get Price -

Buy gypsum powder production line you need to know about .

10/06/2021 · Select the gypsum powder production line and gypsum making machine manufacturer. Nowadays, there are many manufacturers of gypsum powder machines such as Raymond mills, and the level is also uneven, and it is also very important to choose a manufacturer with a good aftersales service. ... the basic process flow of ore production, .

Get Price -

agricultural gypsum powder production process ore machine .

Used Gypsum Powder Machine for sale. Raymond equipment ... Desulfurization Gypsum Gypsum Powder Making Machine. Manufacturer: Yurui Chemical Gypsum Powder Production process Raw material request Main quality indexes of raw materials CaSO4·2H2O content: 75% ~ 95% Surface water content ≤ 18% Crystal water content 1820% Capacity 15,000ton400,0...

Get Price -

Gypsum Manufacturing

A flow diagram for a typical gypsum process producing both crude and finished gypsum products is shown in Figure In this process gypsum is crushed, dried, ground, and calcined. Not all of the operations shown in Figure are performed at all gypsum plants. Some plants produce only wallboard, and many plants do not produce soil ...

Get Price -

China Gypsum Powder Making Process Factory and Suppliers ...

Gypsum Powder Making Process Manufacturers, Factory, Suppliers from China ... Auto Gypsum Block Production Line,Natural Gypsum Block Making Equipment. Welcomes all abroad close friends and retailers to ascertain collaboration with us. We are going to give you with genuine, highquality and successful company to satisfy your requirements. ...

Get Price -

process of manufacturing gypsum powder

Gypsum powder production process. The purpose of gypsum powder is mainly used in building materials and the pharmaceutical industry, also differ due to different purposes of its processing technology, mainly lies in its fineness, purity and analyze two different purposes under the gypsum powder processing technology Because the gypsum powder ...

Get Price -

6 Facts about Synthetic Gypsum

FGD Gypsum is Created at Power Plants FGD gypsum is formed when fossilfueled power plants utilize flue gas desulfurization systems to remove sulfur dioxide from gas pollutants. Using a process referred to as 'scrubbing,' gas pollutants are fed through calcium carbonate to eliminate impurities and environmental concerns.

Get Price -

FGD Gypsum Uses And Process Technology

04/09/2021 · FGD Gypsum Powder Processing Technological Process. Phrase one: raw material crushing. FGD gypsum will be crushed to 15mm20mm fineness by crusher. ... Phase four: production collecting. Qualified powder will flow with the air and be collected in the dust cher, and then the finished powder will be transported to the product storage bin ...

Get Price -

Gypsum Powder Production Plants

Gypsum Based Dry Mortar Production Plants. Plasterboard Production Plants. Plasterboard Recycling Line. Plasterboard Ceiling Tile Production Plants. Dry Mortar Production Technologies. Perlite Processing Technologies. Praget Lime Technologies. Calcite Processing Technologies. Equipment for Cement industry.

Get Price -

GYPSUM PLUS MINES LIMITED

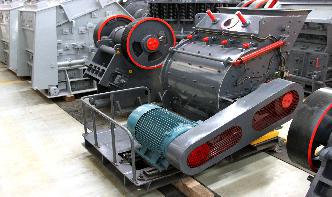

Gypsum Powder Production Line The Crusher will break the bigsize gypsum ore into small 25mm pieces, and then the small pieces will be sent to the grinder, aftergrinding fine, the qualified raw gypsum ppowdwer will be sent to boilling furnace to calcine, and the unqualified part will be sent to grinder until it's qualified.

Get Price -

CNA

The method comprises the following steps: firstly, preparing building gypsum, packing powder, plasticizing agent, adjustable solidifiion agent, waterproof agent and mixing water into a gypsum...

Get Price -

MATERIAL AND ENERGY BALANCE OF PRODUCTION OF GYPSUM FLUIDIZATION PROCESS

16/10/2009 · In this work, the coefficient of heat utilization and participation in the price of energy products were calculated, based on theoretical and actual data on energy consumption. In this factory,...

Get Price -

Five stages of gypsum production process

Gypsum production process. Gypsum ore, from quarries and underground mines, is crushed and stockpiled near a plant. Asneeded, the stockpiled ore is further crushed and screened to about 50 millimeters (2 inches) in diameter. ... and cyclone collector will gather the final gypsum powder for final appliion.

Get Price -

Gypsum Powder Ultrafine Grinding Mill

In the process of gypsum production and processing, a gypsum powder ultrafine grinding mill is indispensable. Generally speaking, the process of the gypsum production line is as follows: first, crush the gypsum ore to meet the particle size requirements of the mill; then use the ultrafine mill for grinding treatment; then enter the boiling furnace for heating treatment, and .

Get Price -

Gypsum

Synthetic gypsum is produced as a waste product or byproduct in a range of industrial processes. Desulfurization [ edit] Flue gas desulfurization gypsum (FGDG) is recovered at some coalfired power plants. The main contaminants are Mg, K, Cl, F, B, Al, Fe, Si, and Se.

Get Price -

Phosphogypsum powder processing

Grinded phosphogypsum powder will be classified, coarse powder will fall back to the main mill to be ground again. Phase four: production collecting qualified powder will flow with the air and be collected in the dust cher, and then the finished powder will be transported to the product storage bin through discharge port.

Get Price -

The production process of building gypsum powder

The production process of building gypsum powder. Gypsum into gypsum and anhydrite. Building gypsum from two natural gypsum calcination temperature or chemical gypsum after heating to certain, two water gypsum dehydration decomposition, grinding to obtain semi hydrated gypsum as the main component of the product beta hemihydrate gypsum, gypsum .

Get Price -

diagram for manufacturing process of gypsum powder pdf

Gypsum powder production line (natural gypsum) uses advanced processing equipment such as a vertical mill, boiling furnace, etc. The boiling furnace is the most widely used gypsum calcining equipment in China, and is applied to calcining process of natural gypsum and chemical gypsum. production process of gypsum

Get Price -

Gypsum

Gypsum rock is first mined or quarried, then crushed and ground to a fine powder. It then goes through a process called calcining where heat at 350 degrees is supplied to the gypsum powder which removes 3/4 th of the water molecules. Hemihydrate is the name of calcined gypsum which is then used in gypsum board, gypsum plaster, and other products.

Get Price -

Precision casting gypsum powder production process

Precision casting gypsum powder production process. ... manufacturing costs of a product cost of materials processing and assembly are determined by design decisions with production decisions such as process planning or machine tool selection responsible for only 20 The heart of any design for manufacturing system is a group of design ...

Get Price -

Gypsum processing and use

Production processes Gypsum processing plants vary widely in scale and level of technology. They range from plants producing one or two tonnes per day using lowcost manual technologies, to plants of a thousand tonnes per day that are highly mechanized and capable of producing different types and grades of gypsum plaster or plaster boards.

Get Price