-

Iron Ore Processing

Mar 05, 2015 · In iron ore crushing plant, customers usually choose a complete iron ore production line for higher efficiency. At present, the most popular iron ore production lines consists of two jaw crushers....

Get Price -

Products › Ironmaking and steelmaking › Iron ore processing ...

Beneficiation and Pelletizing plant. 1/115. ... nowadays more than 75% of the DR grade pellets worldwide and it is the only technology capable to successfully process different source of iron ores assuring the maximum flexibility to the pelletizing plant. Configurations: Beneficiation: Crushing, grinding, magnetic separation and flotation; ...

Get Price -

Ore separating line,Ore beneficiation,Ore processing plant,Iron ore ...

In 1996, the selected iron ore was million tons which accounts for % of the amount of undressed ore production of million tons. Next, experts from Henan Mining Machinery Co., Ltd will give a detailed introduction to its beneficiation technology and equipment used of the Ore processing plant. 1. Rock crushing:

Get Price -

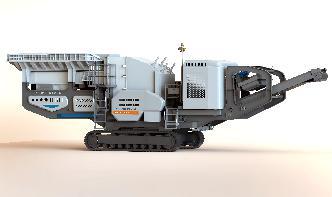

Iron ore crushing and screening process

Aug 03, 2022 · Iron ore is an important raw material for iron and steel production enterprises. Natural ore (iron ore) gradually selects iron through procedures such as crushing, grinding, magnetic separation, flotation, and gravity separation. In theory, any ore containing iron or iron compounds can be called iron ore.

Get Price -

BENEFICIATION OF IRON ORE

Iron ore is used in production of pig iron which is further used in production of steel other uses of iron ore are like industrial finishes, polishing compounds and sponge iron industries. Iron ore belongs to Precambrian stage and its deposit is present in .

Get Price -

The Most Effective Lithium Ore Processing Method You Must Know

Jul 20, 2022 · Building an efficient lithium ore processing plant An effective lithium ore processing plant mainly includes crushing line, grinding line, beneficiation line, and some auxiliary equipment. The most commonly used production equipment is crusher (jaw crusher, impact crusher, cone crusher), ball mill, flotation machine or magnetic separator, etc.

Get Price -

2022en11pew/jiangtai ed iron ore processing at main ...

Contribute to gcmcrusher/2022en11pew development by creating an account on GitHub.

Get Price -

crushing,screening and washing plant for iron ore

31/12/2012 · iron ore screening plant. Screening is carried out at various stages in the crushing process. Screens are basically box frames into which sheets of screen meshes of the required apertures are inserted, clamped and tensioned. Screens are usually "multideck",, two or more screen meshes are stacked vertically within the screen frame.

Get Price -

Northern Iron Ore Beneficiation Works

Northern GOK is a monopolist in the iron ore market in Ukraine, making up 45% of total iron ore pellets and about 20% of merchant concentrate. Northern GOK incorporates: the Annovskyi and the Pervomayskyi quarries, which in total constitute 3,807 Mtonnes of mineral resources; cyclicalandcontinuous crushing plant, launched in 2006

Get Price -

Iron Ore Processing

Mar 05, 2015 · Iron Ore Processing Report this post ... Beneficiation. Iron Ore Crushing: The most commonly used crushers in iron ore crushing plant are jaw crusher, impact crusher, hammer crusher and high ...

Get Price -

The Six Main Steps of Iron Ore Processing | Multotec Canada

14/03/2018 · Screening and diverting fine particles significantly increases the performance of the crusher. 2. Crushing and stock piling. This step involves breaking up the iron ore to obtain an F 80 grind size before it can be ground. Once the ore has been crushed, it is diverted to a stockpile. The aim of this step is to ensure a smooth crushing process ...

Get Price -

Products › Ironmaking and steelmaking › Iron ore processing ...

Iron ore processing Beneficiation and Pelletizing plant. 1/115. In a modern pelletizing plant the use of straightgrate technology ensures: Higher availability and capacity creep above 7 Mtpy; Raw material flexibility; ... Beneficiation: Crushing, grinding, magnetic separation and flotation;

Get Price -

Copper Ore Processing Plant, Iron Ore Processing Plant, Tin Ore ...

Email: market Send Inquiry Get Latest Price Production Line Profile The ore processing plant is divided into copper ore processing plant, iron ore processing plant, tin ore processing plant, magnetite iron ore beneficiation line and chrome ore beneficiation plant etc.

Get Price -

Iron Ore Beneficiation Plant In Zimbabwe

Iron ore magnetic separator Characteristics of ore beneficiation process inspiratory capacity and low power consumption. tank has three functions of suction, suction and flotation, and it is a selfforming flotation circuit. It does not need any auxiliary equipment and is horizontally arranged to facilitate the process change.

Get Price -

Iron Ore Beneficiation Plants

Ore Processing Plant covers feeder, crusher, ball mill, classifier, vibrating screen, rocking bed, magnetic separator, mix tank, flotation machine and so on. Ore dressing plant can be used for magnetite, hematite, siderite, limonite upgrading with high efficiency and low cost. Specific: The extracted ore should be crushed by jaw crusher initially.

Get Price -

Iron Ore,Production Process of Iron Ore,Iron Ore Beneficiation .

Production Process of Iron Ore Generally, the processing of iron ore needs several processing stages, including crushing, grinding, ore beneficiation, concentrating, drying, etc. The equipments for iron ore beneficiation is consisted of Jaw Crusher, Ball Mill, Classifier, Magnetic Separator, Flotation Machine, Concentrator Machine and Dryer ...

Get Price -

Iron Ore Crusher 2018

Oct 15, 2017 · Iron Ore Beneficiation Plant. ... The Iron cone crusher is widely used in the largescale iron ore processing or crushing plant. In term of production efficiency and costs, the usage of cone ...

Get Price -

Characterization and Beneficiation of Dry Iron Ore Processing Plant ...

Sep 18, 2018 · Iron ore is the basic raw material for iron and steel making. India is among the leading producers of iron ore in the world and produces about 150 million tons per annum (U. S. []).The total reserves of iron ore in India is around billion tons, of this hematite ore is considered to be the most important iron ore because of its high grade quality and lumpy nature.

Get Price -

iron ore processing plant in malaysia | Mining Quarry Plant

Apr 10, 2013 · HK firm to set up iron ore processing plant. Company's Malaysian unit to build plant in Pahang once deal is pushed through. A HONG KONGBASED company has its sights set on iron ore mining and processing in ..

Get Price -

Iron ore processing plant

2. Jaw crusher is for crushing the iron ore 50230mm, then to the fine jaw crusher. 3. Spiral washing machine is for washing the size 050mm then to the fine jaw crusher. 4. Fine jaw crusher is for crushing the iron ore to 020mm then to the ball mill. 5.

Get Price -

Iron ore processing plant

28/09/2017 · Generally, the processing of iron ore needs several processing stages, including crushing, grinding, ore beneficiation, concentrating, drying, etc. The equipments for iron ore beneficiation is...

Get Price -

Ore separating line,Ore beneficiation,Ore processing plant,Iron ore ...

Several techniques such as washing, jigging, magnetic separation, advanced gravity separation and flotation are being employed to enhance the quality of the Iron ore. Due to the high density of hematite relative to silies, beneficiation usually involves a combination of crushing and milling as well as heavy liquid separation.

Get Price -

Iron Ore Processing Plant in Ethiopia

Aug 31, 2021 · Zenith's dry magnetic separator is widely used in the iron mining industry in Ethiopia. It can meet the requirements of small, medium and large iron ore processing plant in Ethiopia. The Magnetic Separators are available in cyclic design with process vessel diameters smaller than 3mm. Its magnetic system is a ringshape chain closed magnetic ...

Get Price -

Iron Ore Processing Plant

The magnetic separation process is used as the main method of iron ore beneficiation. The iron ore process is advanced and the utilization rate of magnetite can reach 90%. And the configuration parts cited in the magnetite beneficiation production line are all wearresistant materials, which can greatly improve the efficiency of the equipment.

Get Price