-

Iron Ore Tailing Beneficiation – a Potential Resource for Future

20/01/2022 · Tailing beneficiation of iron ore has been addressed either by flotation or wet high intensity high gradient separation. The present study aims to recover iron values from discarded slime containing assay ~56% Fe, ~% SiO2, and ~% Al2O3 from Noamundi processing plant by using high gradient magnetic separator (HGMS).

Get Price -

Bhushan Power and Steel

In 2010 Mineral Technologies began design of a startoftheart solution for a new Iron Ore beneficiation plant for Bhushan Power and Steel in India. Bhushan Power Steel's engineers collaborated closely with Mineral Technologies' metallurgists to review test results and ensure process flowsheets met specific requirements.

Get Price -

Research on the Beneficiation Experiment of Iron of a Tailing Ore ...

The tailing sample containing % Fe was subjected to this experimental and taken from Yunnan. After a series of beneficiation tests, the iron concentrate assaying % Fe at a yield of % was obtained by process flow – weak magnetic and strong magnetic discarding tailing in advance, rough concentrate regrinding and weak magnetic – table recleaning, and .

Get Price -

Essar Steel Turnaround

Mar 16, 2016 · The stateoftheart facilities comprise iron ore beneficiation, Pellet making, iron making, steel making, and downstream facilities, including a cold rolling mill, a galvanizing and precoated facility, a steelprocessing facility, an extrawide plate mill and 3 pipe mills with coating facilities.

Get Price -

Corem | Discover our stateoftheart equipment

We offer stateoftheart equipment to ensure you specialized services, whether punctual or long term, in mineral processing. ... Assessment of beneficiation potential of ore bodies: Drill core characterization: ... Corem is an active member of the ISO/TC/102 committee for the development of ISO standards for iron ore and direct reduced iron ...

Get Price -

Iron ore

Lowergrade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the concentration of the ore and remove impurities. The results, highquality fine ore powders, are known as fines. Magnetite [ edit]

Get Price -

Iron ore beneficiation: Matching local raw materials with the .

David Cousins. In recent months, the government of South Africa has made significant efforts to achieve greater control of its resources and create more employment opportunities and economic growth for the wider community. In the leadup to IMM's inaugural Iron Ore Beneficiation Africa conference, we had the chance to speak to David Cousins, Industry Champion for Mining and .

Get Price -

Mines Ministry recommends policy for beneficiation of lowgrade iron .

20/08/2022 · "A concession of 5 per cent in the rate of royalty on the quantity of lowgrade ore beneficiated through the wet process and 10 per cent concession on the rate of royalty on the quantity of lowgrade ore beneficiated through dry process may be given on 20 per cent of the annual production of iron ore of all grades," it said. Published on

Get Price -

BENEFICIATION OF LOW/OFF GRADE IRON ORE: A REVIEW

01/08/2020 · According of Zhang (2006) this method upgrade the percentage of iron from % to %, it means that recovery of iron was calculated %. The beneficiation of iron ore is relatively more effective, when RAF operation applied along with magnetic concentration. Data indie that it enhance the Fe% value from 29% of Fe to 50 % Fe.

Get Price -

Iron Ore | SGS United Kingdom

07/06/2022 · Iron ore is an important commodity currently in high demand due to population and infrastructure growth in developing countries. Verify Documents, Clients Products ... Beneficiation Services. pdf . Advanced Mineralogy for Iron Ore. pdf . InPlant Expertise for Iron Ore. pdf . Trade and Inspection for Iron Ore.

Get Price -

: Beneficiation

20/07/2022 · Beneficiation is any process which removes the gangue minerals from ore to produce a higher grade product, and a waste stream. Beneficiation may involve physical or chemical processes. Often, as in the case of panning for gold, the desired ore or metal is denser than the gangue. The latter can be suspended in a stream of water and flushed away.

Get Price -

iron ore beneficiation state of the art

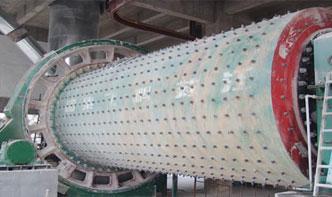

The project is a two stage spiral plant for beneficiation of fine iron ore 10mm to Mineral Technologies supplied state of the art click to chat now Feb 23 linq to ascii art iron ore beneficiation plant india mineral processing plant india iron ore processing plant india sand . .

Get Price -

Iron Ore | SGS USA

06/06/2022 · Iron ore is an important commodity currently in high demand due to population and infrastructure growth in developing countries. ... Beneficiation Services. pdf . Advanced Mineralogy for Iron Ore. pdf . ... 201 Route 17 North, 7th and 8th Floors 07070, Rutherford, New Jersey, USNJ, United States. News Insights. View all. View ...

Get Price -

Mines Ministry recommends policy for beneficiation of lowgrade iron ore

Aug 20, 2022 · A committee set up by the Union Ministry of Mines has recommended steps for beneficiation and upgradation of lowgrade iron ore into higher grade ones. Recommendation states that at least 80 per ...

Get Price -

Pellet manufacturing plant at GUA iron ore mines in Jharkhand

Mar 19, 2015 · March 19, 2015. New Delhi: Steel Authority of India Limited (SAIL) will invest about Rs. 4749 crore to enhance its iron ore production capacity of the iron ore mines of Gua in West Singhbhum District of Jharkhand. This includes an outlay of about Rs. 2743 crore to set up state of the art crushing, beneficiation and pelletisation plant facilities.

Get Price -

Iron Ore Distribution across the World

24/01/2016 · Beneficiation = Improve Concentration of Iron Ore is either Hematite (Fe2O3) or Magnetite (Fe3O4) and the iron content ranges from 50% to 70%. This iron rich ore can be charged directly into a blast furnace without any further processing. Iron ore that contains a lower iron content must be processed or beneficiated to increase its iron content.

Get Price