-

iron processing | Britannica

Direct reduction, in which iron ores are reduced at temperatures below the metal's melting point, had its origin in such experiments as the WibergSoderfors process introduced in Sweden in 1952 and the HyL process introduced in Mexico in 1957. Few of these techniques survived, and those that did were extensively modified.

Get Price -

Iron ore crushing plant, iron ore beneficiation and mining .

Mining and processing of iron ore involves coarse crushing and screening. Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening. This is usually so efficient that lower grade ore can be treated especially when .

Get Price -

Iron ore beneficiation | Commodities | Mineral Technologies

We offer a range of mineral process solutions, services and equipment across all stages of the project lifecycle. From metallurgical test work, concept and prefeasibility studies, through to plant design, equipment supply, and commissioning. Our products Gravity separation Electrostatic separation Magnetic separation Spare parts Our solutions

Get Price -

irons process of mining

Iron processing Britannica. Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a Iron Mining Process From blasting to crushing to separation – more than 85% of the iron .

Get Price -

Process Of Crushing Iron Ore Kiribati

process of crushing of iron orexinhai global. Iron ore crushing process kidscityministry. 2018 7 25 Iron processing: Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and o. View Details Send Enquiry

Get Price -

Mining | McLanahan

Crushing. McLanahan offers a variety of crushing solutions to reduce minerals such as coal, salt, granite, copper and iron. Minerals are liberated from the waste rock and reduced in size through the primary, secondary and tertiary stages of crushing, by equipment that utilises impact, attrition, compression or shear forces.

Get Price -

crushing iron ore mining equipment

Contribute to gcmcrusher/2022en11pew development by creating an account on GitHub.

Get Price -

(PDF) SIZE REDUCTION BY CRUSHING METHODS

04/03/2017 · Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by ...

Get Price -

Crusher Plant | Mineral Aggregate Processing

1. Working flow: The main crushing process step is material – screening – rough crushing – middle crushing – rescreening – fine crushing – washing sand – discharge. 2.

Get Price -

Metal ore mining in Europe

This mine incorporates the ore seams of Suuri and Roura, which were put into openpit operation in 2008 and 2010, respectively. In 2012, operations were completely converted to underground mining. The mine was expanded in 2014 to 4500 t/d of ore, and by 2021 a further 25 % capacity expansion is planned with a roughly 1050 m deep shaft.

Get Price -

Iron Ore Analysis Process Optimization Solutions

Jul 27, 2017 · During the entire iron ore production process, we deliver tailored analytical solutions for exploration geologists, mine planners, process engineers as well as for geometallurgists and quality managers. Improve recovery rates and Iron ore beneficiation Watch on Iron ore mining Predictive realtime analysis in the mine Learn more

Get Price -

Mineral Processing

The 3 courses in mineral processing will give your employee an NQF Level 4 qualifiion. Other popular courses include crushing, thickening of a slurry, water reticulation and handling of chemicals. Our full range of Underground Mining courses are detailed below. Contact us for more information. Mineral processing courses

Get Price -

What Equipment Are Needed to Process Iron Ore?

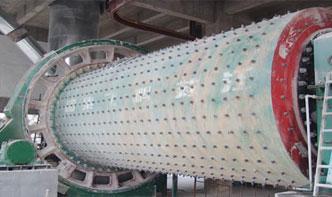

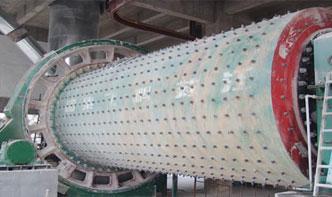

23/09/2017 · 1. The crushing system: The crushing system is generally composed of coarse jaw crusher, fine jaw crusher, sand maker and ball mill. The primary task of coarse jaw crusher is to break largeblock ...

Get Price -

Basic Mining Process Of Iron Ore

basic mining process of iron ore crusher in India. Grinding Mill. Grinding is the required powdering or pulverizing process when final size of below 2 mm is needed. Shenbang can provide the proper grinding measure to ... iron ore mining process enmining.

Get Price -

Iron Ore Crusher/ Iron Ore Processing Plant/ Iron Ore Crushing .

Technological Process of iron ore crushing plant is: Iron ore transported by the dump truck Vibrating feeder Jaw crusher (Primary crusher) Spring cone crusher (Secondary crusher) Circular vibrating screen finished product as .

Get Price -

HOW DOES MINING EQUIPMENT WORK IN IRON ORE MINING?

28/06/2017 · Hematite and limonite, magnetite and goethite, the mining operation is extracting the rock and crushing it until the rocky deposits are evenly sized. Remember, the deposits are somewhat soft, even crumbly, but there's raw iron trapped inside the ore. Given time, the ore will age the mining equipment, deform the system parts, and hamstring ...

Get Price -

Iron Ore Mining Crusher Sale Prices

Iron Ore Sag Mill Manufacturer India,Iron Ore Sag Mill For Sale .. Iron Ore Sag Mill or SAG mill and grid screen and gravel crusher together in a . america gold mining company; oil shale crushing plant; crusher machine parts for sale .

Get Price -

Extraction of Iron from its ores, Iron dressing, Reduction production ...

23/10/2018 · The ore dressing. The aim of ore dressing is increasing the concentration of iron in the ore by removing the unwanted impurities and improve the properties of the ore which helps in the successive stages of extraction, The ore dressing process is carried out to improve the physical and mechanical properties of iron ore and includes Crushing process, Sintering .

Get Price -

Metallic Minerals Processing

process of separating valued minerals from the matrix rock. The number of crushing steps necessary to reduce ore to the proper size vary with the type of ore. Hard ores, including some copper, gold, iron, and molybdenum ores, may require as much as a tertiary crushing. Softer ores, such as some uranium, bauxite, and titanium/zirconium ores, require

Get Price -

Iron ore crushing processing |

17/06/2020 · IRON ORE CRUSHING PROCESSING PLANT. Put the mm iron ore into the hopper, through the vibration motor vibrating material, the quantity can be made precise adjustment by hand wheel. ... while the gangue grains is thrown off to in front of the compartment mine board when the magnetic roller to the front end position(by changing the angle ...

Get Price -

Ore Sorting | Preceding Processing | Ausenco

19/03/2019 · Auranen explained: "The FCA analyses ore continuously on a conveyor typically loed after primary or secondary crushing giving average grades of the ROM bulk ore in short (five to 60 second) time frames.

Get Price -

Iron ore crushing plant, iron ore beneficiation and mining .

SBM supply iron ore crushing plant, iron ore beneficiation and mining equipment to processing iron can get the abundant whole iron ore processing such as the working machine report,pdf,pic,video. ... Chinese Shanghai SBM design the iron ore mining process flow chart including crushing, screening, washing and grinding process for the ...

Get Price