-

Iron Ore

17/02/2022 · Iron Ore. Item type Crafting material Material type Stone Crafting 16 13 20 Rarity Basic Cost 18 Value 1 Patch ...

Get Price -

Iron Ore

29/08/2022 · Our Iron Valley site, loed within the Pilbara, is currently our largest iron ore producing mine, outputting approximately 8 Million tonnes of iron ore per annum. Product from this mine is transported to Utah Point for export to our global markets. In 2018, we acquired the Kumina Iron Ore Project from BCI Minerals Limited. Kumina is loed ...

Get Price -

iron ore processing plant process description

Processing of Iron ore in India 8 Slimes of Iron ore 11 3. BENEFICIATION PLANT STUDY OF NOAMUNDI ... Fig Flowchart for beneficiation of iron ore slime 44. Read More.

Get Price -

Iron ore – Anglo American South Africa

Our business. Kumba is a supplier of highquality iron ore to the global steel industry and is focused on creating shared value with a range of stakeholders. Iron ore is the key component in steel, the most widely used of all metals. In South Africa our iron ore operations are made up of a % shareholding in Kumba Iron Ore Limited (Kumba), a ...

Get Price -

Integrated processing of highigrade iron ores | Request PDF

01/01/2014 · Request PDF | Integrated processing of highigrade iron ores | An integrated nonwaste technology for processing of the Yakovlevskoye deposit highgrade iron ore has been developed, permitting to ...

Get Price -

iron ores processing magnetic roll separator

16/05/2015 · # Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic the concentration of iron ore other than magnetite, after preliminary conversion of iron minerals to artificial magnetite by suitable magnetic roll is enveloped by the conveyor.

Get Price -

Mineral Commodity Summaries 2022

Domestic Production and Use: In 2021, mines in Michigan and Minnesota shipped 98% of the domestic usable iron ore products, which were consumed in the steel industry in the United States, with an estimated value of billion, a 23% increase from billion in 2020. The remaining 2% of domestic iron ore was produced for nonsteel end uses.

Get Price -

complete process of iron ores pilot production

Aug 15, 2020· Iron Production. The production of iron from its ore involves an oxidationreduction reaction carried out in a blast furnace. Iron ore is usually a mixture of iron and vast quantities of impurities such as sand and clay referred to as gangue. The iron found in iron ores are found in the form of iron oxides.

Get Price -

Top Challenges Impacting Growth of the Iron Ore Market

19/10/2017 · China has faced a significant blow due to such laws as it is the biggest importer of iron ore. Huge Capital Requirements. Iron ore mining requires substantial capital investments due to energyintensive nature of the extraction process. For instance, the average cost of an iron ore project was around US236/tonne of capacity in 2014.

Get Price -

The Process of Making and Refining Steel from Raw Iron

27/04/2017 · There are two types of the modern steelmaking process: Primary Steelmaking This process chiefly utilizes new iron samples as the feedstock from a blast furnace. Secondary Steelmaking The ...

Get Price -

Iron Ore

Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel. 98% of the mined iron ore is used to make steel. Minnesota's iron ore was actually discovered while prospectors were searching for gold. Since the object of their search was gold, the iron was ignored. It turned out the iron would become ...

Get Price -

Iron Mining Process

At the processing plant, the taconite is crushed into very small pieces by rock crushing machines. The crushers keep crushing the rock until it is the size of a marble. The rock is mixed with water and ground in rotating mills until it is as fine as powder. Separation The iron ore is separated from the taconite using magnetism.

Get Price -

USA1

USA1 US11/572,298 USA USA1 US A1 US A1 US A1 US A US A US A US A1 US A

Get Price -

From the Soil to the Iron Product

15/05/2014 · During this process the water content of the iron ore is released, and its structure becomes looser, which makes it easier to smelt. Finally, we break up the burnt iron ore into 23 cm pieces to make it easier to load the iron ore into the furnace during the smelting process (See Figure 3). Step 3. Building furnaces.

Get Price -

Iron Ore Pelletizing Process: An Overview

The iron ore pelletizing process consists of three main steps: 1. Pelletizing feed preparation and mixing: the raw material (iron ore concentrate, additives anthracite, dolomite and binders are prepared in terms of particle size and chemical specifiions, dosed, and mixed together to feed the pelletizing process; 2.

Get Price -

iron: | Infoplease

For many years rich hematite ores were produced by openpit mining in the Mesabi Range near Lake Superior. However, these ores have been largely depleted, and iron is now produced from lowgrade ores that are treated to improve their quality; this process is called beneficiation. Iron ores are refined in the blast furnace. The product of the ...

Get Price -

The Six Main Steps of Iron Ore Processing | Multotec Canada

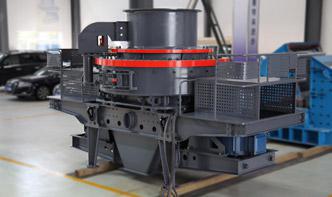

14/03/2018 · Screening and diverting fine particles significantly increases the performance of the crusher. 2. Crushing and stock piling. This step involves breaking up the iron ore to obtain an F 80 grind size before it can be ground. Once the ore has been crushed, it is diverted to a stockpile. The aim of this step is to ensure a smooth crushing process ...

Get Price -

An Overview of Steelmaking Process, Global Market Size, .

The first metallurgical step involved in this process is to reduce iron ore to metallic iron in a blast furnace, using coke as both a fuel and reducing agent. The produced metallic iron contains a relatively high proportion of carbon (4%) and it is passed to the steelmaking process in the form of liquid at approximately 1450 C, called as 'hot ...

Get Price -

Raw Material In Iron Making

03/04/2010 · Technology. In this presentation, I have tried to explain main raw material sources of iron making process. Also, with my experience, I have tried to give a concept about the plant engineering related to raw material. I hope that, this presentation will be helpful for young engineers. With this presentation they will get a broad idea about the ...

Get Price -

Top five iron ore producing companies in 2020 by mining output

10/05/2021 · 1. Vale – 300 million tonnes. Brazilian miner Vale was the world's top producer of iron ore in 2020, with an output totalling just over 300 million tonnes – a small decline from 2019 when it produced 302 million tonnes of the metallic ore. The Carajás mine in northern Brazil is Vale's largest operation and is among the biggest iron ore ...

Get Price -

USB2

USB2 US11/572,298 USA USB2 US B2 US B2 US B2 US A US A US A US B2 US B2 US B2 Authority

Get Price -

Electrolysis of Iron Ores: Most Efficient Technologies

19/07/2019 · In MOE processes, iron ore is dissolved in a molten oxide mixture at 1823–1973 K (1550–1700 °C). The anode, made of a material inert towards the oxide mixture, is dipped in this solution. Electrical current is passed between this anode and a liquid iron pool connected to the circuit as the hode. Oxygen evolves as a gas at the anode, and ...

Get Price -

iron ore concentrate processing

On the way from the mine to a final product, the iron ore goes through the following main process segments: 1 The iron ore is crushed and the waste rock is removed. Inquire Now; Iron ConcentrateECOEnglish Wiki. Oct 06, 2020Iron Concentrate is created by purifying Crushed Iron Ore. This can be done in one of two ways either dry og wet purifiion.

Get Price -

How Is The Iron Ore Mined?

19/04/2019 · Natural iron ore is gradually selected from iron by means of crushing, grinding, magnetic separation, flotation, reelection, etc. Iron ore is a mineral aggregate that can be economically utilized with iron or iron compounds. Any ore containing iron that can be used economically is called iron ore. There are many kinds of iron minerals, and ...

Get Price