-

Recycled plastic building materials (bricks made from waste?!)

Possible to produce a sustainable concrete that's 10 to 40 per cent lighter than conventional versions. Builders are more productive with lightweight materials, so less money is spent on transportation and labour. Heavyduty resistance against chemicals and solvents. Thermoplastics are flexible and can be reshaped easily.

Get Price -

Recycled Aggregate Concrete

15/11/2014 · What Is Recycle aggregate concrete. 6. Characteristics of recycle aggregate concrete Recycle aggregate concrete has a Crushed sound and clean waste concrete of at least 95% by weight of concrete with typical total contamination lower than 1% of the bulk mass Class 1A RCA is a well graded RCA with no more than % brick content. 7.

Get Price -

Why the world is running out of sand

08/11/2019 · The concrete used to construct shopping malls, offices, and apartment blocks, along with the asphalt we use to build roads connecting them, are largely just sand and gravel glued together. The...

Get Price -

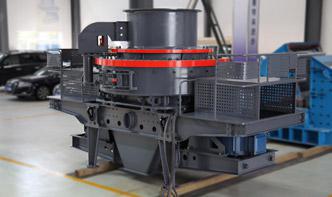

Manufactured sand – a solution to the global sand shortage?

30/11/2020 · The use of manufactured sand makes sense from various perspectives. First, manufactured sand is more uniform in structure compared with natural sand. It also has an advantage when it comes to concrete production, because manufactured sand is less needed in the concrete mix by a margin of 5 to 20% compared with natural sand to fill the voids ...

Get Price -

Review of Research on and Implementation of Recycled Concrete .

Dec 25, 2011 · The goal of sustainable construction is to reduce the environmental impact of a constructed facility over its lifetime. Concrete is the main material used in construction in the Gulf Cooperation Council (GCC). Therefore, it makes economic and environmental sense to use recycled materials in the making of new concrete for different appliions. The objectives of .

Get Price -

How to make moulds for concrete | BECOSAN®

03/10/2018 · With a knife or hot wire (for smoother edges) cut out the desired cavity and fill it with concrete. If you only want to make the walls of the concrete mould from Styro, Styrodur or the like, you can glue them to a wooden, cardboard or plastic base plate. Also note that the base plate should not soak. DIY 3: Plaster mould for concrete casting

Get Price -

Recycling old glass into better concrete

Jul 14, 2019 · Concrete is one of the most used construction material, and sand is one of its primary components. Once mined, the sand needs to be wasted and graded before it can be mixed with aggregate, cement and water to make concrete. Polymer concrete is a type of concrete that uses polymers, typically resins, to replace lime cements as a binder.

Get Price -

Could Desert Sand be Used to Make Concrete?

13/04/2018 · In 2015, Mental Floss discussed the reason desert sand could not be used to make the concrete. They explained that, because it is windswept, the sand is too fine and won't achieve the texture of waterswept sand in manufacturing. Given the amount of waterswept sand left and how mining is beginning to go beyond riverbeds and onto beaches, new ...

Get Price -

Recycled Glass Countertop : 10 Steps (with Pictures)

The countertop contains 75 pounds of recycled blue glass and 50 pounds of Surecrete's Terrazzo Mix. The color is CHENG's SmartColor Indigo and the entire project is sealed with Surecrete's PC12 Concrete Sealer. The high amount of recycled content would qualify this countertop for LEED credits and only takes a few hours to form and cast.

Get Price -

Carbon Footprint of Recycled Aggregate Concrete

30/05/2018 · Emissions for concrete with w/c were between 347 and 351 kg of CO 2 e /m 3. It was also corroborated that cement is the material with the greatest influence on greenhouse gas emission generation in the concrete's production phase, regardless of the use of recycled or aggregates. 1. Introduction.

Get Price -

making recycled concrete to sand

30/04/2022 · How to Install Concrete Pavers, Start by spreading roughly two inches of crushed concrete evenly over the soil The crushed concrete is an aggregate Step 3 lay out conduit pol work on sand in small sections Screed Sand Lay out the conduit poles about two feet apart Image 1 Since you will not be able to walk on the sand once it,...

Get Price -

Cement Stabilised — Concrete Recyclers

Cement ratios can be blended from 2% (50:1) up to 12% (8:1) Please refer to your engineering specifiions for which ratio is suitable for use on your project. Cement Stabilised: DGB20 Recycled DGS40 Recycled Envirosand / Recycled Sand Sydney Sand Water modified: DGB20 Recycled DGS40 Recycled

Get Price -

Crushed rock sand – An economical and ecological alternative to .

Sep 01, 2016 · The results of the study show that, the strength properties of concrete using crushed rock sand are nearly similar to the conventional concrete. The study has shown that crushed stone sand can be used as economic and readily available alternative to river sand and can therefore help to arrest the detrimental effects on the environment caused ...

Get Price -

Why the world is running out of sand

08/11/2019 · Others are developing concrete that requires less sand, while researchers are also looking at more effective ways to grind down and recycle concrete. In many Western countries, river sand mining ...

Get Price -

How Much Ballast Do I Need To Mix Concrete? | TJC Transport

Aug 07, 2019 · One of the most important factors in making concrete with your required strength is the cement to water ratio. Using less water makes the concrete stronger, and using excess water will make the concrete less workable. Also, using too much water leads to segregation of the sand and aggregate particles and cause microscopic pores in the concrete.

Get Price -

Ecofriendly concrete made from recycled glass waste? TPM .

The team has created ecofriendly concrete that's cheaper, stronger and more lightweight than traditional concrete (made from sand, fly ash, slag and other materials). "Our work has shown it has excellent sound, thermal insulation and fireresistant characteristics," researcher Dr Ali Kashani told The Fifth Estate.

Get Price -

Construction and demolition waste as recycled aggregate for ...

10/09/2021 · Recycled aggregates (RA) from construction and demolition waste (CDW) instead of natural aggregates (NA) were analysed in the manufacture of new ecofriendly concrete. Fine (FRA) and coarse (CRA) recycled aggregates were used in different percentages as substitutes of natural sand and gravel, respectively.

Get Price -

Aggregate Size In Concrete | Coarse Vs Fine Aggregate

Feb 03, 2022 · Coarse aggregate is any material whose particles are anywhere from 3/8 inches and inches in width. This is the size of aggregate often used in road construction. Fine aggregate: Most fine aggregates consist of crushed stone or natural sand. Most of the present particles must be able to pass through a 3/8inch sieve.

Get Price -

(PDF) Recycling Waste Plastic Bags as a Replacement for Cement .

01/03/2020 · Abdel Tawab et al. (2020) studied waste plastic utilization as a replacement for cement in bricks and concrete blocks. They reported that there is a decrease in thermal conductivity for both bricks...

Get Price -

How To Make Cement And Concrete From Scratch

To test, take a cup and fill the cup with your concrete solution. At first as you add water it will retain its shape when turned over and the cup removed. As you add water the test cup of concrete will settle more and more. You want it to settle to about half of the original height.

Get Price -

These 10 Everyday Items Create Unbelievable Concrete Designs

To unleash their creative spark, first use a pair of needle nose pliers to break the insulators enclosing the metal tip of the bulbs. Thoroughly clean the emptied bulbs with a lintfree cloth...

Get Price -

Material made from desert sand matches concrete's strength

04/04/2018 · Finite, a newly developed biodegradable material made from desert sand, matches concrete's strength but has half of the carbon footprint, reported Dezeen. Using desert sand, which is smooth ...

Get Price