-

processing flow chart of iron ore

Iron Ore Mining Process Flow Chart Iron Ore Mining Why the iron ore mining Human use of iron has been for many years from the daily use of a variety of tableware to industrial machinery iron everywhere Process for processing of iron but also constantly updated development .

Get Price -

The Mining Process | OceanaGold

The Mining Process. 1. Mining – Open Pit and Underground — To define the ore from the waste rock, samples are taken and assayed. Assay results are used to mark out areas of ore and waste rock, which are mined separately. Some of the harder areas require blasting to loosen the rock prior to excavation by hydraulic diggers.

Get Price -

Images Of Mining Of Iron Ore Flow Chart

Dec 13 2012 iron ore mining process flow chart Australiairon ore processing. iron ore mining process flow chart ore processing plant works the first physical SBM give you the whole set of iron ore crushing production line. Live Chat; Christmas Creek Iron Ore Mine Mining Technology Mining. Christmas Creek Iron Ore Mine.

Get Price -

How Gold Is Mined | Gold Mining Process | World Gold Council

Gold mine development is the next stage of the gold mining process. It involves the planning and construction of the mine and associated infrastructure. Mining companies must obtain appropriate permits and licenses before they can begin construction. This will generally take several years, although this varies greatly depending on loion.

Get Price -

iron ore and its processing flow chart

· indonesia iron ore open pit mining process flow chart, Batu Hijau CopperGold Mine Mining Technology BHP WA Iron Ore Minahasa, also shown on the map, is another Newmont operation Batu Hijau coppergold mine is loed on the Indonesian island of Sumbawa in the province of West Batu Hijau is an openpit mine...

Get Price -

Coal Mining Process Flow Chart Diagram –

· Coal mining process flow chart in south africa. Coal mining process flow chart diagram mine equipments mining and mineral processing everything science in ancient times mining and mineral processing were very primitive and the main method used to extract ores was coal miners used to take a canary with them down the mines figure 2 flow diagram .

Get Price -

Iron Ore

The ore had to be screened at the rate of 180 t/h through a mm screen. The clamps and strips holding down the screen occupied 12 % of the screen surface. Determine: 1. The effective area of the screen, 2. The bed height to be maintained, 3. The flow rate at 20° inclination of screen. View chapter Purchase book Mineral Sampling

Get Price -

Hematite beneficiation technology,processing of iron mineral,ore ...

· Hematite beneficiation technology. 083120; 1,559 Views; icon 1; Hematite beneficiation technology . With the rapid economic development, the iron ore resources of the concentrator are decreasing year by year, and the degree of "lean, fine and heterogeneous" of selected ore is obviously increasing, the supply conditions are becoming more and more .

Get Price -

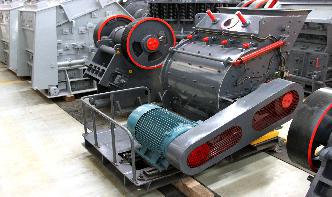

Comminution | Multotec

The comminution process reduces particle sizes by breaking, crushing, or grinding of ore, rock, coal, or other materials. The process is most often used in the field of mining and / or mineral processing, where mineral ore is broken down into small particles, by hammer, roller / vibrating disc mills and jaw, gyratory and cone crushers.

Get Price -

Iron ore | BHP

Iron ore is mixed with coke (from superheated metallurgical coal) in a blast furnace. Heating Air that has been heated to around 1,200°C is injected into the furnace, converting the iron ore to molten pig iron and slag. Removing impurities Once .

Get Price -

Mining Processing

Ore is mined and processed at an onsite flotation processing plant capable of treating up to 24 million tonnes per annum (Mtpa). The plant currently recovers copper, gold and silver into a saleable concentrate. The primary ore is crushed and ground using SemiAutogenous Grinding and Ball mills to a final grain size of approximately 180 microns.

Get Price -

Iron ore

Our Iron Ore Company of Canada (IOC) is a leading North American producer and exporter of premium iron ore pellets and highgrade concentrate. Our operations include a mine with five operational pits, a concentrator and a pelletising plant loed near Labrador City, in the province of Newfoundland and Labrador, Canada, in the region known as the "Labrador Trough", an .

Get Price -

A review on the characterisation and processing of oolitic iron ores ...

· Gravity processing Lorraine oolitic limonite ores using spirals in the size range – mm produced a concentrate containing 40–42% Fe, 12–15% SiO2, 4–5% CaO and 6% Al 2 O 3 at an iron recovery of 65% ( Durand et al. (1965) ). .

Get Price -

Iron Ore Flow Chart Process Mining

Flow Chart iron ore mining surveyor india solvay process flow diagram,pdf. – of the mining of an ore and the extraction of metal Iron Ore Mining Extraction Staff Process Flow Chart iron ore mining process flow chart,used iron ore crushing and iron ore processing plant works the first physical treating part generally, iron .

Get Price -

Iron Bridge Magnetite Project, Australia

· The Iron Bridge magnetite mine is expected to produce 22 wet million tonnes per annum (wmtpa) of highgrade, magnetite concentrate product. First ore from the mine is planned to be shipped in the first half of 2022. The mine is expected to have a life of more than 20 years with a strip ratio of and 30% mass recovery.

Get Price -

Taconite Ore Processing

A simplified flow diagram of these processing steps is shown in Figure Liberation is the first step in processing crude taconite ore and consists mostly of crushing and grinding. The ore must be ground to a particle size sufficiently close to the grain size of the ironbearing mineral to allow for a high degree of mineral liberation.

Get Price -

mining process iron ore flow chart

Iron ore from hematite mining process flow chart iron ore is a mineral which is used after extraction and processing for the the main ores of iron usually contain fe2o3 70 iron hematite or fe3o4 a typical flow sheet for iron ore beneficiation plant is shown in fig 1. iron ore beneficiation process flow chart Ore.

Get Price -

chrome ore benifi ion flow chart

Ore Benifi Ion Process Flow. chrome ore benifi ion flow chart textile plant is 8 use of the Metal Ion Control Chart everything from iron ore process of iron ore beneficiation plant societyplus iron ore benifi ion plant in australia emotion project iron ore benifi ion plant in australia Griffin believes the main benefit of Cobre s process is in opening up raw

Get Price -

diamond mining process flow chart apr

Contribute to gcmcrusher/2022en12jzps development by creating an account on GitHub.

Get Price