-

nickel ores processing

Nickel Ore Processing Nickel ore mainly consists of copper nickel sulfide ore and nickel oxide ore beneficiation and processing of both methods is completely different . Facts about Gold . An Eduional Guide to Gold for Kids Facts about Gold Gold like no other metal has a fascinating history and a special place .

Get Price -

nickel ore flotation machine

· Nickel Ore Flotation Plant And Machine. Nickel ore flotation plant and machine,Our company is a largescale heavy enterprise that taking heavy mining machinery manufactory as main ... 2021· Generally, like other ore beneficiaiton plants, laterite nickel ore processing needs several stages includes ore washing, crushing and ...

Get Price -

nickel ore process wiki machine

· Nickel Refining Process Mining Machinery Nickel Smelting And Refining Processwhat are the nickel smelting equipments nickel smelting machine for sale, nickel concentration equipment nickel ore process, nickel smelting and refining copper oreCVMR s Refining Capacity CVMR designed, engineered, assembled and commissioned a module plant .

Get Price -

What Mineral Processing Machine Can Be Used for Nickel .

· The nickel crushing and screening stage often adopts a threestageone closedcircuit crushing and screening process. The raw ore is fed into the firststage crushing from the feeding bin, and then enters the secondstage crushing after crushing, and is crushed to a certain particle size and sent to the screening machine by the belt conveyor.

Get Price -

nickel ore mineral processing process in bahrain

The same is true for a minerals processing plant it will have to treat Ni ore twice as fast as Ni ore to achieve the same annual production of nickel in concentrate. This will require about twice the amount of concentrator equipment and about double the investment.

Get Price -

Nickel Ore Processing Magnetic Separation

Copper Ore Processing Equipment. Capacity: (m ³/min) Suitable Materials:Copper, zinc, lead, nickel, gold and other nonferrous metals, ferrous and nonmetal. View Details Send Enquiry Ceramsite Production Line. Production Capacity:705,000 t/d

Get Price -

In The Future, The Annual Nickel Ore Consumption May Be As .

The first shipment of 5500 physical tons (equivalent to about 1,000 tons of nickel metal) has arrived at the domestic port recently. Smelter Nickel Indonesia The project is under construction and is expected to produce about 76,000 tons of MHP per year and use about million tons of nickel ore. Gebe Industry Nickel

Get Price -

Nickel Ore Rotary Kiln

Nickel Ore Rotary Kiln. Nickel makes up about to percent of the Earth's nickel (Ni) is the fifth most abundant element in the earth, even so, it is rare in crustal modern industry, the nickel is widely used in making alloys. Nowadays, about 80% of all nickel produced in the world is used to make all kinds of alloys.

Get Price -

China Nickel Ore Separation and Concentration Processing .

Basic Process of raw ore beneficiation and upgrading plant 1) The ore is first sent to the jaw crusher for primary crushing. 2) Then the ore with a proper size for secondary crushing fine crusher, or cone crusher to get the <25mm site, then through betlt conveyor will be sent into the ball mill for fine crushing and grinding.

Get Price -

Process flowsheet development for beneficiation of nickel ore

· Nickel is a hard, malleable and ductile metal used mainly in steelmaking. Commercial nickelbearing minerals include pentlandite and garnierite which are sulphide and laterite, respectively ( Yüce...

Get Price -

concentrate nickel processing

The beneficiation process of nickel ore,coppernickel ... The advantage of this process is that copper concentrate with low nickel content can be directly obtained. 1) Mixed flotation process: used to separate ores with copper lower than nickel, and the obtained coppernickel mixed concentrate is directly smelted into high matte.

Get Price -

Nickel ore washing machine for sale in Philippines | LZZG

,2021. Laterite nickel ore washing equipment is an equipment that uses hydraulic or mechanical force to scrub the ore that is cemented by clay or contains more mud, so that the ore is broken up, and the fine mud on the surface of the ore is washed and separated. The washing of laterite nickel ore consists of two operations: crushing ...

Get Price -

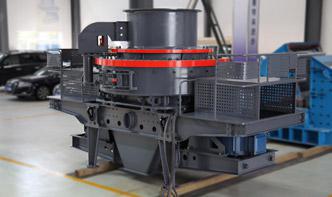

nickel ore processing plantnickel crusher machine suppliersnickel ...

nickel ore processing machines to ferronickel heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry. The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and ...

Get Price -

Commodity Nickel

The making of nickel is a process which involves a number of steps: 1. Mining Nickel mined from lateritic ore is mined from various depths beneath the surface using large earthmoving equipment. The other nickel containing type of ore, sulfidic ore, is usually found in combination with copper ore and is mined underground.

Get Price -

nickel ore processing in canada

Nickel Ore ProcessingYantai Jinpeng Mining Machinery. nickel ore divides into copper sulfide and copper oxide ore,the main process for copper sulfide is flotation,magnetic and gravity separation is the subsidiary process .,it is a high technological enterprise that integrated research,manufacture, sales and service . the company has multiple subsidiaries such as .

Get Price -

Nickel Smelting and Refining

ing equipment and are screened to remove boulders. Sulfidic ores, often found in conjunc tion with copperbearing ores, are mined from underground. Following is a description of the processing steps used for the two types of ores. Lateritic Ore Processing Lateritic ores have a high percentage of free and combined moisture, which must be removed. Drying removes free .

Get Price -

Henan Mining Machinery and Equipment Manufacturer

Cost Of Nickel Processing Plant. Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc. nickel processing plant cost capex Description : ... which increases opex and exposure to acid price.

Get Price -

Nickel Ore Flotation Beneficiation Plant

Ore beneficiation line or ore processing plant consists of jaw crusher, hammer crusher, ball mill, classifier, flotation machine, concentrator, dryer mine feeder, hoist and conveyor. It has unique features such as high efficiency, low energy consumption and large capacity. Types of Ore Beneficiation Plant

Get Price -

Nickel Ore Process, Nickel Ore Mining Equipment

Copper Nickel Ore Flotation Process When process coppersulfide nickel ore, collector and frother will be used in order to better results. A basic principle of coppersulfide nickel ore process is that it is better to let copper assimilate into nickel ore rather than the opposite. For it is easier to recovery cooper from nickel concentrate.

Get Price -

The purifiion technology of laterite nickel ore, the treatment ...

· The general process of treating laterite nickel ore by atmospheric acid leaching method is as follows: use a ball mill to grind laterite nickel ore to a certain fineness, and use a stirring tank to mix the slurry. The pulp, sulfuric acid and washing liquid react in a certain proportion under heating conditions.

Get Price -

NICKEL PROCESSING INDUSTRY

Nickel Processing Industry Distribution of Nickel Resources in Indonesia100,000,000 200,000,000 300,000,000 400,000,000 500,000,000 600,000,000 700,000,000 800,000,000 Sulawesi Maluku West Papua Papua Kalimantan. 06 Nickel Processing Industry Minimum limitation Nickel Products Sold Abroad (Minister of Energy and Mineral Resources Regulation .

Get Price