-

roasting laboratory rotary kiln

laboratory rotary kiln for roasting and sintering test of materials Main uses and characteristics: It is suitable for roasting and sintering test of materials in metallurgy, geology, mining, chemical industry, building materials and scientific research .....

Get Price -

MAGNESIUM OXIDE (MgO) PLANTHenan Zhengzhou Mining .

Equipment configuration: rotary kiln, singlecylinder cooler, cyclone preheater, centrifugal fan, kiln end bag filter. The calcination of magnesite to produce magnesium oxide requires MgO>45%, and % for the ores used for calcination. The essence of magnesite calcination is the decomposition of carbonate: MgCO;=MgO+CO2.

Get Price -

nickel ore rotary kiln calcination

Laterite nickel ore calcining process: preparation of ore treatment and reducing agent rotary kiln calcination hot loading into the submerged arc furnace smelting desulfurization of crude nickel iron removal of silicon, phosphorus and carbon in the converter, sulfur, manganese and other impurities refined nickel iron ore cast block, the other need to build recycling and the .

Get Price -

[Hot Item] Rotary Kiln for Burning Laterite Nickel Ore

China Rotary Kiln for Burning Laterite Nickel Ore, Find details about China Rotary Kiln for FerroNicel Calcining, Rotary Kiln for Laterite Nickel Ore Calcination from Rotary Kiln for Burning Laterite Nickel Ore Jiangsu Pengfei Group Co., Ltd.

Get Price -

FL to supply rotary kiln, rotary dryer and other equipment .

· FL has been chosen as the supplier of the rotary kiln and rotary dryer for the Araguaia Niquel Metais Ltda ferronickel mine in the state of Pará in the Northern region of Brazil. The order...

Get Price -

Lateritic nickel ore deposits

Lateritic nickel ores formed by intensive tropical weathering of olivinerich ultramafic rocks such as dunite, peridotite and komatiite and their serpentinized derivatives, serpentinite which consist largely of the magnesium silie serpentine and contains approx. % nickel. This initial nickel content is strongly enriched in the course of ...

Get Price -

Modelling and optimization of a rotary kiln direct reduction

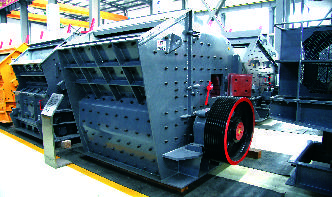

Rotary kilns (Figure 1) are used for a range of mineral processing operations. Kilns range in size from 2–6 m in diameter and can be 50–225 m long with an operating mass of up to 3000 t. Two of the most common appliions are for cement production and sponge iron production.

Get Price -

Rotary Kiln – IspatGuru

· Other appliions – Other appliions of the rotary kiln include (i) oxidation of ilmenite, (ii) calcination of iron ore pellets after preliminary heat treatment on a traveling grate, (iii) calcination of petroleum coke, (iv) reduction of heavy spar, (v) processing of gypsum to sulphuric acid and cement (gypsum – sulphuric acid process), (vi) production of TiO2 pigment, .

Get Price -

energy saving mining ore rotary kiln calcination process plant

Laterite nickel ore calcining process: preparation of ore treatment and reducing agent rotary kiln calcination hot loading into the submerged arc furnace smelting desulfurization of crude nickel iron removal of silicon, phosphorus and carbon in the converter, sulfur, manganese and other impurities refined nickel iron ore cast block, the other need to build recycling and the usage of .

Get Price -

Vertical Shaft Kiln Calcinate Laterite

· The process of calcination of the laterite nickel ore rotary kiln can be divided into the following steps laterite nickel orewater grindingslurry filtrationaddition of limestone and anthracitemixing by rod millpressinggrate heating Machine preheatingrotary kiln calcinationwater quenchingwater grindingjiggingmagnetic separation ...

Get Price -

Complete Production Laterite Nickel Calcination Rotary Kiln .

High quality Complete Production Laterite Nickel Calcination Rotary Kiln 12000t/D from China, China's leading 12000t/d Calcination Rotary Kiln product, ... Ore Grinding Mill (121) Stone Crusher Machine (112) Castings And Forgings (113) ...

Get Price -

horizontal rotary kiln active lime calcination plant limestone .

Horizontal Rotary Kiln Active Lime Calcination Plant Limestone Calciner Furnace Low Price, Find Complete Details about Horizontal Rotary Kiln Active Lime Calcination Plant Limestone Calciner Furnace Low Price,Horizontal Rotary Kiln Active Lime,Quick Lime Calcination Plant,Limestone Calciner Furnace from Cement Making Machinery Supplier or Manufacturer .

Get Price -

Lateriatenickel ore rotary kilnProduct

Lateriatenickel ore rotary kiln Jiangsu Pengfei Group has the 300,000tpy machinery manufacturing base, has the 13m vertical lathe, diameter 12m, 40 die hobbing processing capacity, 8*20m annealing furnace and 400t max. lifting capacity which could meet the manufacturing requirements of producing rotary kiln and ball mill with diameter less than 10m.

Get Price -

CNA

the invention also discloses elevated shortprocess energysaving novel rkef ferronickel alloy production equipment, which is mainly composed of a rotary kiln, a drying kiln, an electric furnace...

Get Price -

How to Extract Laterite Nickel Ore? 7 Processing Methods

· This article will introduce you to these 7 laterite nickel ore processes. Jump To A Section: 1. Rotary kiln drying and prereductionelectric furnace reduction smelting method 2. Sintering blast furnace vulcanization smelting method 3. Sintering blast furnace reduction smelting method 4.

Get Price -

Effect of particle size in the reduction of lateritic Ni ore in a ...

Colombia possesses Nickel ore in the highlands of the San Jorge region, south of the department of Cordoba. The material extracted from the area is processed by means of calcination and fusion in a Rotary Kiln and an Electrical Arc Furnace EAF respectively to obtain the Ferronickel.

Get Price -

energy saving mine equipment alumina rotary kiln nickel laterite kiln

Roofting Construction HTML Template. powered by a rich history of efficiency and value Alumina Refining Mineral Processing Solvent Extraction of the substantial size and contribution of the mining equipment technology for nickel cobalt laterites and also for two processes under development Rotary kiln calcination with electric furnace smelting

Get Price -

China Rotary Kiln Manufacturers, Suppliers, Factory

Nickeliron Rotary Kiln Ferronickel is a kind of metal compound with high iron content. Its comprehensive utilization value is very high, and its appliion field is quite extensive. Read More Alumina Rotary Kiln Alumina bauxite is widely used in the construction industry.

Get Price -

Rotary KilnHenan Zhengzhou Mining Machinery

Rotary kiln refers to rotary calcining kiln, mainly used for calcining calcium aluminate, limestone, bauxite, kaolin clay etc, which is widely used in the fields of building materials, metallurgy, chemical industry, environmental protection, etc. Customers' Installation Site Features 1. New type technology is adopted by main driving system.

Get Price -

What is a rotary kiln? Basic classifiion and appliion

· The working principle of the rotary kiln is composed of the processes of gas flow, fuel combustion, heat transfer and material movement. The rotary kiln is how the fuel can be fully burned, and the heat of fuel combustion can be effectively transferred to the material, and the material will be generated after receiving the heat.

Get Price -

calcined rotary kiln bauxite for sale, calcined rotary kiln bauxite .

86% refractory calcined bauxite/rotary kiln bauxite ..., round or shaft kilns at high temperatures of 1600℃1800℃. This process of calcining (heating) bauxite in kilns removes moisture and gives Calcined Bauxite its high alumina content and refractoriness, low iron, and grain hardness and toughness.

Get Price -

Rotary Kiln Calcination Plant In New Caledonia

Rotary kiln a rotary kiln is a processing device used for calcinating and sintering a broad range of materials like cement clinker ferrites and dry powder with a capacity ranging from 300 td to 10000 td our rotary kiln is widely used in various industries such. Get .

Get Price -

nickel ore rotary kiln calcination

Rotary Kiln For Nickel Ore, Rotary Kiln For Nickel Ore ... offers 71 rotary kiln for nickel ore products. About 54% of these are cement making machinery, 14% are industrial furnace.

Get Price -

Materials | Free FullText | Coupled Preparation of Ferronickel

· The laterite nickel ore is placed in the rotary kiln for drying intervention reduction at a temperature of 650–800 °C, and then placed in the reducing furnace at 1550–1600 °C for smelting and sorting to obtain coarse nickel iron. Nickel–iron alloys containing more than 25% nickel can be produced after further refining [ 36 ].

Get Price