-

Oil Pressure Problems in Refrigeration Systems | ACHR News

12/05/2000 · Oil pressure trips can be caused by electrical problems. An electrical problem that causes the motor windings inside the compressor to overheat can cause internal overload in the compressor to open. The compressor is not operating and not producing oil pressure, yet the oil pressure control is still energized and monitoring the oil system.

Get Price -

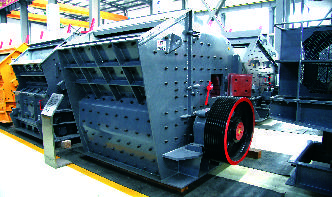

Crusher

Crushing is accomplished by compression of the ore against a rigid surface or by impact against a surface in a rigidly constrained motion path. Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers. Primary Crusher

Get Price -

cone crusher | Henan Deya Machinery Co., Ltd.

27/06/2022 · according to the site environment and operating conditions, the cone crusher normal oil temperature should be maintained at 3855 ℃, the best working temperature state in the range of 3846 ℃, if the temperature is too high and with continuous operation, it will cause the inside bushing damage, the main shaft may be broken, too, and .

Get Price -

Clearing metal tramp blockages in cone crushers | SafeWork SA

SafeWork SA is reminding businesses to ensure safe systems of work are in place when using and maintaining crushing plant. In April 2020, a worker received fatal injuries when attempting to clear a metal tramp blockage in a cone crusher loed in a quarry. The crusher was not in operation at the time of the incident.

Get Price -

How to apply coolant and cutting fluid in turning

There are a number of different coolant medias used when turning: Emulsion, a mix of water and oil (510% oil in the water) is the most common coolant media. Oil, in some machines oil is used instead of emulsion. Compressed air, used for chip evacuation but does not take away heat in a good way. MQL minimum quantity lubriion compressed ...

Get Price -

Crusher Maintenance Manual

06/11/2019 · If your crusher is being used regularly in extreme heat (plus 100 degrees F) or cold temperatures (minus 10 degrees F) and it is hard to maintain crusher oil in the correct operating range, it may be helpful to switch to synthetic oil. Inspect the main frame. Inspect the main frame bore for nicks, burrs, scoring, or other damage.

Get Price -

operating pressure of cooling oil in cone crushers

An alarm system is an integral part of this lube system During the operation of certain cone crushers, an alarm may sound if any of the following abnormal conditions occur for more than five seconds: a low feedline oil flow; a low feedline oil pressure; Maintenance of Hydraulic System of Cone Crusher (2, 1 The crusher prevents excessive oil ...

Get Price -

5 tips for energy efficient and productive cone crushing

15/04/2020 · This inefficient use of connected horsepower will result in a higher energy cost per ton of material crushed (kW/hr per ton). Approximately 70% of the total lube oil flow rate is being used to keep the cone crusher cool. When the actual lube oil flow rate decreases below 70%, the crusher will operate warmer than previously.

Get Price -

QH331 cone crusher Technical specifiion sheet

QH331 cone crusher Technical specifiion sheet ... • Hydraulically driven cooling fan allos speed control producing increased ... CONSTRUCTION MOBILE CRUSHERS AND SCREENS LTD HEARTHCOTE ROAD SWADLINCOTE DERBYSHIRE DE11 9DU ENGLAND TEL +44 (0)1283 212121 FAX +44 (0) 1283 217342 .

Get Price -

Hydraulic Cone Crusher Manufacturers, Suppliers Exporters in .

Salient Features: The Cone crusher can provide customers a higher capacity, better product shape, and easy to operate High crushing ratio and production efficiency Less spare part consuming and low operation cost Thin oil lubriion makes the service time increased Easy to maintenance and operation

Get Price -

Operation and maintenance of cone crusher in mobile crushing station

18/02/2021 · In operation (1) When the oil temperature is heated to 2530 degrees, start the oil pump motor for 510 minutes, and then check the working condition of the lubriion system. The oil pressure is Observe that the oil return pipe is normal and the oil quality meets the requirements before starting the main motor.

Get Price -

Maintenance of Hydraulic System of Cone Crusher | China Crusher .

18/06/2021 · When the crusher is at a normal ambient temperature, the gear pump should be 50 °C, 18—38pf/s oil. When the temperature is high, the crusher machine can't run continuously for too long. The crusher usually has a continuous working time of 4 hours under the condition that the temperature is higher than 30 °C.

Get Price -

Solutions for high temperature oil shutdown of cone crusher

19/05/2020 · The running current of the cone crusher is set at 3035a. If the current is too high, the cone load will be too high, which will cause the temperature of the cone and the lubriing oil to rise;...

Get Price -

CH840i CONNECTED CONE CRUSHER

Overpressure fan Air/oil coolers Offline filter functions ELECTRICAL HARDWARE Lubriion control Connection modules tank Cable kit CABINET DIMENSIONS Lubriion control cabinet (LxHxD) 1200x800x250 mm HYDROSET SYSTEM System design Single reversible pump Oil tank reservoir capacity 85 liters Pump design Gear pump Pump capacity l/min 50 ...

Get Price -

Cone crusher equipment lubriion system work common sense

it is summer or winter, should run the cone crusher to make the lubriing oil temperature rise, oil return temperature must be 39 ℃ ~ 54 ℃; cooling system will keep the oil temperature in the safe operating range. Therefore, you must use the right type of lubricant to ensure the crusher good operation;

Get Price -

oil coolers for cone crushers

operating pressure of cooling oil in cone crushers. oil coolinng system oil pressure switch for cone crusher . CH890i CH895i CONNECTED CONE CRUSHER WATER/OIL COOLER (OPTION) No. of units 1 Dry weight 150 kg Material Stainless steel Mounting Stand alone Oil volume 13 liters Oil pressure drop MPa Oil flow rate 260 l/min (50 Hz) 266 l/min ...

Get Price -

CNA

The invention discloses a positive pressure dedusting structure for a cone crusher. The positive pressure dedusting structure comprises an upper rack, a slide ring cover, a lower rack and a...

Get Price -

Industrial crushing plant: Description of cone crushers Cone Crusher ...

Description of cone crushers Cone Crusher uses the lubricant seal, the flaw that for the water and therefore the drainage system has avoided...

Get Price -

Extrusion

02/10/2013 · Barrels for most extruders are designed to withstand operating pressures up to 10,000 psi or 700 bar. Normal operating pressures generally range between 1,000 and 5,000 psi. or 70 and 350 bar. Too much pressure could rupture a barrel. To protect the extruder barrel from overpressurization, several methods have been developed.

Get Price