-

The Aerodynamics of an Iron Ore Pelletizing Rotary Kiln

· This paper summarizes more than a decade of systematic studies of the flow field in an iron ore pelletizing rotary kiln using computational fluid dynamics (CFD) on simplified models of a real kiln. Physical, laserbased experiments have been performed to validate part of the numerical results.

Get Price -

Recovering Iron from Iron Ore Tailings and Preparing Concrete

30%, the quality of mineral admixtures was not reduced. Last but not least, reusing the highsilica residues during iron recovery enabled the complete utilization of the IOTs. Keywords: iron ore tailings; iron recovery; concrete composite admixtures; reuse 1. Introduction Iron ore tailings (IOTs) are a form of solid waste produced during the beneficiation process of iron ore .

Get Price -

pelletizing iron ore concrete qualities

Home / pelletizing iron ore concrete qualities . Pelletizing of Iron Ore Big Bag Pelletizing of Iron Ore Big Bag Supplier of Iron Ore provide Cheap Iron Ore from .. Home Products About Us Quality Control Cont. Read More.

Get Price -

download pelletizing of iron ores kurt meyer pdf

Pelletizing Of Iron Ores Kurt Meyer Kurt Meyer Pelletizing Iron Ores Gloriavitali. Kurt meyer pelletizing iron ores free downloadpelletizing of iron ores kurt meyer scribd read books, pelletizing iron ore hematite 13116,pelletizing of iron ores kurt meyer free ebook download as pdf file pdf, text file txt or read book online for free this book is a .

Get Price -

pelletizing iron ore concrete qualities

· Iron Ore Pelletizing Know More. Quality /Certifiions About, They include continued demand for iron pellets in China and India to satisfy, the iron ore pelletizing industry has finally ....

Get Price -

Outotec wins iron ore pelletizing plant order in China

· The plant, which will be the fifth large iron ore pelletizing plant delivered by Outotec in China, is based on our environmentally sound traveling grate technology," says Tobias Stefan, Vice President, Ferrous Heat Transfer business line at Outotec. Pellet production at the Zhong Tian plant is estimated to start by the end of 2021.

Get Price -

Iron Ore Pelletizing Plants In South Africa

GrateKiln System For Iron Ore Pelletizing . the plant took iron ore concentrate and produced superior iron ore pellets (which are spheres of high iron content and uniform quality) for blast furnace and direct reduced iron feed. since then, gratekiln systems have been used for over 50 plants, on both magnetite and hematite ores, with an ...

Get Price -

increasing iron ore grade by pelletizing

Pelletizing Iron Ore Concrete Qualiti owing to increasing steel demands in developing countri However the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking This chapter shows the status of...

Get Price -

WOA1

The composition of the invention comprises bentonite and molasses. The invention also refers to process for preparing iron ore pellets wherein a composition comprising bentonite and molasses is...

Get Price -

Fives Energy | Combustion

Fives develops a wide range of superior industrial combustion solutions for all ferrous metal processes : steel, forging, heat treatment, iron ore pelletizing, and ferrous nickel. We offer tailormade and standard solutions that maximize production and efficiency while reducing NOx and carbon emissions . Burners: from our wide range of burner ...

Get Price -

download pelletizing of iron ores kurt meyer pdf

All of our equipment have got ISO international quality system certifiion, European Union CE certifiion and Russian GOST certifiion. Contact Info. Jianye Road, South Jinqiao Area, Pudong, Shanghai, China + [email protected] Products. Home; Products; Skf Bearing Mill For Bms mendozina. Pelletizing is the process of compressing or molding a .

Get Price -

Pelletizing Iron Ore Concrete Qualities

Pelletizing Iron Ore Concrete Qualities Industry News fundamental of pelletizing iron ore ppt MTM130X Ultrafine Mill MTM Series Trapezium Mill XZM Series. 【 】 Iron ore pelletization Iron Ore 15. A brief introduction to recent developments in .

Get Price -

Utilization of High Sulfur Raw Materials in Iron Ore Pellets

· Abstract Pyrite cinder and high sulfur magnetite were used as raw materials to produce iron ore pellets. Good qualities of green balls and fired pellets were obtained from the feed comprising 50% pyrite cinder and 50% high sulfur magnetite concentrate at a small scale. Smallscale tests were proven by pilotscale tests.

Get Price -

Recovering Iron from Iron Ore Tailings and Preparing Concrete

minerals Technical Note Recovering Iron from Iron Ore Tailings and Preparing Concrete Composite Admixtures Chang Tang 1,2,3, Keqing Li 1,2,*, Wen Ni 1,2,* and Duncheng Fan 1,2 1 Key Laboratory of the Ministry of Eduion of China for HighE cient Mining and Safety of Metal Mines, University of Science and Technology Beijing, Beijing 100083, China; .

Get Price -

Global Iron Ore Pellets Market Size Report,

Blast furnace (BF) pellets dominated the market for iron ore pellets in 2019 with a revenue share of % in 2019. It is a lower grade product when compared to iron pellets used in Direct Reduced (DR) method, and therefore has a lower cost compared to its counterpart. Blast furnace method is usually found in integrated steel plants.

Get Price -

Characterisation of the Physical and Metallurgical Properties of ...

The blast furnace is still the dominant form of iron production, but over the years, direct reduction methods have increased due to a number of reasons. Overall, iron production methods have optimal requirements with respect to the feed materials especially iron ore. In this study, tests were carried out on Muko iron ore from Uganda to analyse its suitability to meet the feed .

Get Price -

pelletizing iron ore machines

Pelletizing Iron Ore Concrete Qualities. Pelletizing Iron Ore Concrete Qualities Pelletiing iron ore concrete qualities 4 6 5553 Ratings The Gulin product line consisting of more than 30 machines sets the standard for our industry We plan to help you meet your needs with our equipment with our .

Get Price -

Other Pelletiing Iron Ore Concrete Qualities

READ and wheat are grown in large quantities near certain iron ore pelletizing facilities and their starches are easily modified to form coldwatersoluble powders that can be used as ore pellets are the raw materials for direct reduction process of iron ore to sponge iron pellets and is an important step in the iron and steel production 04, .

Get Price -

smal concrete iron ore project plant

pelletizing iron ore concrete qualities. May 21, 2019 IRON BRIDGE MAGNETITE PROJECT PACKAGE 662NSC2002 PROCESS PLANT CONSTRUCTION SCOPE OF WORK Iron Bridge Magnetite Project AIP Scope of Work Project Overview IB Operations Pty Ltd (IB Operations), as agent for the joint venture between FMG Magnetite Pty Ltd and Formosa Steel IB Pty Ltd, is .

Get Price -

Granulating Iron Oxide Pigments for Use in Concrete

The earthy tones that can be achieved with iron oxide pigments are an ideal fit for the needs of the concrete industry. But in addition to the colors offered by IOPs, iron oxide has also become the pigment of choice for its other beneficial characteristics, including: Cost effective Nontoxic Color stable Durable and weather resistant

Get Price -

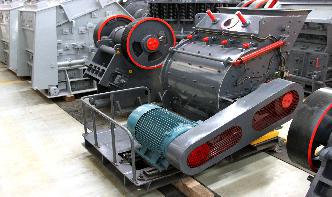

Drum Mixers For Iron Ore Pelletizing | AGICO

The rotary drum mixer is the main equipment in iron ore pelletizing plants, which is set between the batching equipment and the pelletizing disc. It provides wellmixed raw materials suitable for induration. Rotary drum mixers can be divided into gear driving drum mixers and rubber tire driving drum mixers.

Get Price -

Products | CVIC | Iron Ore Pellet Screening Solutions | Roller Screen ...

In the iron ore pelletizing industry, roller screens are commonly used for the preparation of raw materials. Roller screens are used to segregate iron ore pellets of the desired size. It is the preferred solutions for size grading that is an important element in pellet manufacturing. Typically, a roller screen consists of one section of rolls with the same gaps or several sections of rolls ...

Get Price -

ENHANCED BINDERS FOR IRON ORE PELLETING AND CEMENT .

Preferably, the iron ore pellets have improved physical properties such as, for example, a dry compressive strength, a ball drop strength, pellet friability, and/or a tensile strength that is comparable to or greater than iron ore pellets manufactured with .

Get Price