-

CHAPTER11 FUNDAMENTALS OF IRON ORE SINTERING

mixed calcium iron silies are the major mineral phases for fluxed sinter . Sintering is a fast process and it is unlikely that equilibrium will be reached during sintering. The reaction mechanism proposed for self fluxing sinter is summarized below : At °C Crystallisation of iron oxide — hematite Dissociation of CaCO3

Get Price -

Discrete Event Simulation of an Iron Ore Milling Process

as ore feed storage for all process stages. In the next stage, ore with a known tonnage rate per hour is fed to the size reduction section. The final output of this section is two streams of ore with restricted particle siz e distributions (one in the range of 20 to +10 mm and the other in the range of 10 mm) and a tailing stream with particles

Get Price -

sorting process ore iron

Dec 04, 2018 0183 32 China Mining Iron Ore Sorting Equipment Magnetic Separator, Find details about China Separation Equepment, Magnetic Separator from Mining Iron Ore Contact Us, Mining facilities or to process iron ore efficiently, we offer tailormade magnet systems Our sorting equipment, specially developed for mining appliions, enables...

Get Price -

Open Pit Mining Techniques|Surface Mines|Rock or Mineral .

Open Pit Mining. Openpit mining, also known as opencast mining, opencut mining, and strip mining, means a process of digging out rock or minerals from the earth by their elimination from an open pit or borrow. The word is used to distinguish this type of mining from extractive methods that need tunneling into the earth.

Get Price -

Iron Mines in Michigan

· September 11, 2013 TIFF. Google Earth September 11, 2013 KML. In 1844, government surveyors were exploring rugged, lakefilled terrain near Negaunee, Michigan, when they noticed their compasses swung erratically in certain areas. It did not take long to determine why: ancient Precambrian rock layers in the area were laced with bands of iron ore.

Get Price -

THE PROCESS OF DIGGING THE ORE

· THE PROCESS OF DIGGING THE ORE Get the answers you need, now! vigneshkaloji5 vigneshkaloji5 Social Sciences Primary School answered THE PROCESS OF DIGGING THE ORE 2 See answers Advertisement ...

Get Price -

USA

A process for upgrading lowgrade magnetitecontaining iron ore with minimum fine grinding. The dry ore is first comminuted to between about threefourths inch and 10 mesh particle size and magnetically separated. The dry tailing is discarded and the concentrate is ground to between about 20 and 100 mesh and again subjected to dry magnetic separation.

Get Price -

the process from digging of the iron ore from the ground to the ...

Iron ore deposits were loed in a variety of places but Pennsylvania, southern New Jersey, and part of New England had good supplies in rural areas close to the needed forest lands. It took about cords of wood to produce a ton of iron ore. One acre of trees produced 3040 cords of wood, or tons of iron per acre

Get Price -

The Process Of Mining And Exporting Iron Ore

We stopped at a lookout of the Rio Tinto Iron Ore mine. There was a sign at the lookout that said about the process of mining iron ore. The process is. They use explosives and drill to get the iron ore. They get a big machine to load the iron ore on a truck. The iron ore gets processed. They stockpile the iron ore.

Get Price -

New dry iron ore processing technology developed

· The drying process increases particle segregation, with the technology's air classifier able to separate particle sizes down to mm. Whereas existing dry separation processes work for ...

Get Price -

iron mine digging process

Nov 21, 2014· The iron ore that is blasted is stacked and loaded upon large dumpers to be moved to the blast furnaces for smelting process. Benches are made for the process of iron ore mining. Mechanized mining involves creation of benches that are used for the purpose of drilling, blasting, and finally the transportation of the iron ore to the crushing plant.

Get Price -

From Ore to Finished Product

7. Sulfide Ore Refining. The final step in processing sulfide ore copper from the smelter is to make high purity copper hodes. 8. Copper Products Many Uses. Copper hodes are pure copper produced from the processing of copper ores. However, hodes are not in the final form of usage as copper materials. 9.

Get Price -

Dry processing of magnetic iron ores

The iron ore industry has reached the end of an unprecedented period of expansion triggered by China's demand for iron ore. ... C G, Kelly, J R and Skinner, W, 2017. Dry processing of magnetic iron ores addressing cost and environmental issues, in Proceedings Iron Ore 2017, pp 215220 (The Australasian Institute of Mining and Metallurgy ...

Get Price -

Common Iron Ore Extraction Processes

· Single weak magnetic iron ores mainly include hematite, siderite, limonite and hematite (vitrinite) – siderite, to its various kinds and the wide range of disseminated grain size, the extraction of weak magnetic iron ore is also relatively complex, such as gravity separation process, froth flotation process, strong magnetic separation processor combined .

Get Price -

iron mine digging process

Mar 14, 2014· The iron itself is usually found in the form of magnetite (Fe3O4), hematite (Fe2O3), goethite (FeO (OH)), limonite (FeO (OH).n (H2O)) or siderite (FeCO3). The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state.

Get Price -

Iron ore extraction techniques

· Iron ore was won by drilling and blasting ().As mining technology generally developed, so did drilling techniques and the explosives used. Smith (1990) reported that the Cleveland deposit was associated with a very strong stone roof rock (known as "dogger") allowing mine drivages to be selfsupporting. However, he states that in later years where the mining .

Get Price -

Iron ore beneficiation technology and process

· Iron ore beneficiation technology and process. 121720; 2,001 Views; icon 0; Iron ore is one of the important raw materials for the production of pig iron and steel in the iron and steel industry. There are many types of iron ore. According to the magnetic properties of the ore, it is mainly divided into strong magnetism and weak magnetism.

Get Price -

Iron ore extraction techniques

· The deep mining of iron ore is unusual in the modern era, but in northern Sweden, ore is mined from considerable depth largely aided by the appliion of automation and remote control equipment. Kiruna has been chosen as the example for a more detailed review of underground techniques.

Get Price -

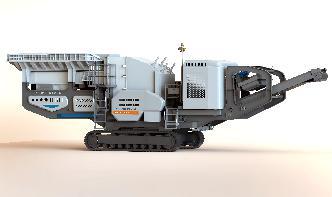

what are the equipment used to process iron ore

process of digging iron ore, The Ore Extraction and Refining Process Before iron ore can be used in a, Mining Equipment XSM operates 11 iron ore mines in ... Iron Ore Processing for the Blast Furnace, a clay from Wyoming used to help iron ore concentrate stick, blast furnace process The iron ore concentrate is ...

Get Price