-

Operation and Maintenance of Coal Handling System in Thermal Power Plant

· Introduction At present, coal is the preeminent fuel of thermal power plant. Continuing up the large unit, and large capacity, the demand of coal is very large. Coal need to process from loading and unloading to stockpile, this .

Get Price -

Coal Mill Processes In Thermal Plant

Home Coal Mill Processes In Thermal Plant. Copper Ore Processing Equipment. Capacity: (m ³/min) Suitable Materials:Copper, zinc, lead, nickel, gold and other nonferrous metals, ferrous and nonmetal. View Details Send Enquiry Ceramsite Production Line. Production Capacity:705,000 t/d Raw Materials:Clay, mudstone, slate, gangue, coal ash, shale, sludge .

Get Price -

thermal power plant processes coal mill

coal mill operation in thermal power plant. The landscape for coalbased power generation is changing rapidly. Coal powerplant Another storage operation, the Snøhvit field ( mill tonnes/year) fired power plant at the Tjeldbergodden Methanol plant and deliver CO2 ( mill tonnes/year) to 90% of thermal power plants are coalfired power ...

Get Price -

COAL MILL PULVERIZER IN THERMAL POWER PLANTS

Crushed raw coal at a controlled rate is fed into the revolving bowl of the Bowl Mill. Centrifugal force feeds the coal uniformly over the replaceable grinding ring where independently spun rolls exert the required grinding pressure. The rolls do not touch the grinding ring even when the mill is empty. of CE Bowl Mills:

Get Price -

coal mill processes in thermal plant

Posted at:March 15, 2013 Gulin machine in iron ore processing plant, processes of coal mill in thermal power plant. Chat Online; get price Patent CNU Mediumspeed coal mill wind sealing . 201146 Mediumspeed coal mill wind sealing device of .

Get Price -

coal mill processes in thermal plant

· Coal mill of thermal power plant, UP, India MR: NO; PR: NO; 2;, Process improvement Liquid metal from blast furnace Cars stand on the conveyor line of,... coal mill process flow cement plant mayukhportfoliocoin, cement plant coal mill, Coal mill pulverizer in thermal power plants 2012, Therefore you continuously monitor the production .

Get Price -

Coal Mill In Thermal Power Plant

coal mill in thermal power palnt html. process integration potentials in coalbased power plants using, coal mill in thermal power plant,oxycombustion is a promising technology for capturing co2 from coal based power plants in a, oxycombustion power plant with a 567mw net power output and a thermal efficiency 31,32 the heat sources,, mills where it is .

Get Price -

Search

Process Integration Potentials in Coalbased Power Plants using, coal mill in thermal power plant,Oxycombustion is a promising technology for capturing CO2 from coal based power plants In a, oxycombustion power plant with a 567MW net power output and a thermal efficiency 31,32 The heat sources,, mills where it is get price

Get Price -

Coal Mill In Mw Thermal PlantHN Mining Machinery Manufacturer

The above diagram is the lay out . of Coal fired (Thermal) power plant. . coal is carried out of the mill by the flow of air ... coal fired power plant process flow diagram BINQ Mining. about 14962 MW which include captive thermal power plants of less than 100 MW installed capacity. The combustion technology in these 86 plants is based on ...

Get Price -

Thermal power station | Thermal energy | ENGIE

The thermal electricity supplied by ENGIE in numerous countries is based on a variety of technologies: Traditional thermal power plants: also called combustion power plants, they operate with energy produced by a steam boiler fueled by coal, natural gas, heating oil, as well as by steam activates a turbine which, in turn, drives an alternator to produce .

Get Price -

Improving Performance and Flexibility of Thermal Power Plants

Coalfired power plants commonly use electrostatic precipitators (ESP) or fabric filters (FF) for particulate control, flue gas desulfurization (FGD) scrubbers for removing SO 2 and other acid gases, and selective alytic reduction (SCR) for NOx reduction. ESP and FF can generally accommodate a wide range of load.

Get Price -

TPH =Tonnes per hour Normalized Thermal Energy due to .

in GCV of coal for Station due to Mills, ID Fans and Ash Handling Plant (Million kcal)} / Gross Generation of AY. THERMAL POWER PLANT Under Perform, Achieve and Trade 33 Final Normalization for the station Normalization (kcal/kWh) = Normalization due to external factors (kcal/kWh) + normalization for PA Fan, Coal Grinding Mill, ID Fan and Ash .

Get Price -

Flexibility in thermal power plants

7 Figure S1: Power generation from nuclear, hard coal and lignite power plants and demand in Germany, 23 to 30 March 2016 12 Figure S2: Qualitative representation of key flexibility parameters of a power plant 12 Figure S3: Minimum load and ramp rates of different hard coal power plants 13 Figure S4: Ramp rates and startup times of different power plant .

Get Price -

thermal power plant processes coal mill

· coal mill for power plant coal mill pulverizer in thermal power plants 17/11/2012 coal, Gulin machine in iron ore processing plant, coal mill in the power .... Know More coal grinding mills for thermal power stations

Get Price -

Adani Dahanu Thermal Power Station | Adani Electricity

Improvement of Coal Mill Performance by Auto Operation Software developed by ADTPS team by studying the correlation between air and coal flow .This logic has helped to avoid undue variation in load and other process parameters even during very heavy rain. Major Milestones: Unit no. 1 was synchronized on 6th January 1995

Get Price -

Thermal Power Plant

· The fuel used in thermal power stations is coal or gas. The heat of combustion of coal is utilised to convert water into steam which runs the steam turbine coupled with the alternator produces electrical energy. Schematic diagram of Thermal Power Plant. The schematic diagram of steam power station is shown in Fig. 1. Fig. 1: Elementary block ...

Get Price -

Coal Mill In Cement Plant, Airswept Coal Mill | Coal Mill

coal mill parts It mainly consists of a feeding device, main bearing, rotating part, driving device, feeding and discharging device, highpressure starting device, and lubriion system. The feeding device includes the feeding pipe, the air inlet pipe, and the support.

Get Price -

thermal power plant processes coal mill

Increasing the flexibility of coal fired power . 16 Sep 2014 Varying number of mills in operation to permit lower loads and greater load range 19 Figure 2 Major process areas of a pulverised coal fired power plant 13 Figure 13 Thermal storage system for increasing plant flexibility

Get Price -

A Innovative Solution to the Problem of Mill Rejects in Thermal Power ...

· A major waste in a pulverized coal fired power plant is the reject produced from pulverizing mills. When coal is ground in a bowl mill heavy mineral matters are separated, but they still contain a small amount of coal mixed. However, the heating value of the rejects is generally too low for combustion in conventional boilers.

Get Price -

What Is a Thermal Power Plant? Operation and Types

· A thermal power plant is an electric plant that converts thermal energy into electrical energy. The difference between one type of plant and another is the way the heat is obtained. The heat sources of a thermal power plant are: Fossil fuels (coal, diesel and natural gas) Nuclear reactions of uranium atoms. Biomass.

Get Price -

Coal based power plant

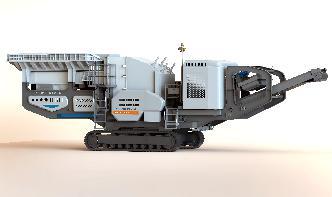

· • A coal handling plant is the area of the thermal power plant where the raw coal is brought from the coal mines and is processed into a form that can fed into the boiler. 1. Transportation System 2. Coal Crusher 3. Coal Storage Area 4. Pulverizer 5. Conveyers Coal Handling SystemCoal Handling System 11.

Get Price -

coal mill processes in thermal plant

types of coal mills used in thermal plants in india. Ball mills in thermal power plant al mill pulverizer in thermal power plants slideshare mills, which grind coal to a target size prior to boiler combustion, are important auxiliary equipment in thermal power 25, is the first mathematical model of power ...

Get Price -

THERMAL POWER PLANTS

2. Process description of a coalfired power plant A coalfired power plant burns coal to produce electricity. In a typical coalfired plant, there are pulverisers to mill the coal to a fine powder for burning in a combustion chamber of the boiler. The heat produced from the burning of the coal generates steam at high temperature and pressure ...

Get Price