-

4 Tips for Winterizing a Crushing Plant

· A better scenario is that you check your heating system and ensure that it's playing its part to keep your crushing plant running. 4. Turn on "winter mode" when you have the option. Finally, if your crushing equipment has a winter mode, you should turn it on during the winter. If that sounds like common sense, it's because it is.

Get Price -

TESPA takes action to halt rock crushing plant

· In doing this, TESPA seeks to prevent Far South Mining LLC (FSM) from moving forward with its proposed quarry operations on 185 acres with activities that involve blasting, operation of heavy equipment, rock crushing and the transport of an estimated at least 100 truckloads of rock per day.

Get Price -

Complete Crushing Operation For Sale

process flow diagram of rock crushing operation. process flow diagram of rock crushing operation is manufactured from ... (process flow diagram of rock crushing ... XSM supplies complete crushing and ... operation of crusher plant BINQ Mining. Jan 20, 2013 · ... August 14, 2012. Complete Crushing Plant – How ... crusher plant operation in ... Crushing and .

Get Price -

Services

A new plant loed in Wood's Colburn Industrial Park is able to provide concrete more affordably to your job site in the greater Sandpoint area, while the batch plant in downtown Bonners Ferry is a great local resource in the northern Panhandle region. Contact Wood's RediMix Concrete in Bonners Ferry at or Sandpoint at ...

Get Price -

Positive Displacement Flow Meter Ensures Proper Lubriion to Rock .

Quarry and aggregate operations typically include some type of crushing machine. These "crushers" are used to reduce large rocks into smaller pieces or rock dust, depending on the requirements of the operation and material being crushed. Crusher machines come in four basic styles: cone, gyratory, impact, and jaw.

Get Price -

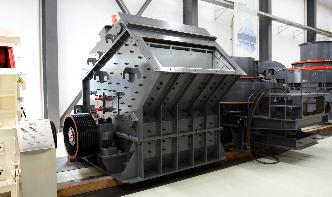

Crushing plant

A Crushing plant is onestop crushing installation, which can be used for rock crushing, garbage crushing, building materials crushing and other similar operations. Crushing plants may be either fixed or mobile. A crushing plant has different stations (primary, secondary, tertiary, ...) where different crushing, selection and transport cycles are done in order to .

Get Price -

Control Of Air Emissions From Process Operations In The Rock Crushing ...

Thus the process areas that must be controlled for fugitive dust in stone crushing beneficiation steps are: • Crushing Operations • Screening Operations • Storage • Transfer Points The number, loion, type, and size of crusher and screens vary from .

Get Price -

Rock Crushing Process Into Various Aggregates

Rock Crushing Process Into Various Aggregates Crushed Stone Grades A Complete Guide By definition crushed stone is a construction aggregate. It is created by mining a suitable rock formation and then using a crusher to break down the stone into different sizes. Live Chat Aggregate Crusher Turn Stone Materials into Building

Get Price -

We Crush Rock Better—Portable and Mobile Rock Crushing for .

We know rock crushing—over the last several decades, we have developed the kind of solid logistics that have allowed us to deploy and operate rockcrushing operations at hundreds of loions, for dozens of customers, in most of the states on the East Coast, including: Arkansas, Florida, Georgia, Indiana, Maryland, Pennsylvania, New Jersey, New York, North Carolina, .

Get Price -

2022enposjx/flow chart of pper at main

Here are five tips for good flowchart design. Applying them will allow you to make flowcharts that are easier to read, understand, and use. 1. Use Consistent Design Elements. Shapes, lines .

Get Price -

Crushed Rock Quarrying Process Flowchart

Process Flow Diagram Of Rock Crushing Operation. How Stone Crusher Process Chart. Stone crusher process flow chart najtanszeoc Stone crusher process flow chart Stone quarrying is the multistage process by which rock is extracted from the ground and crushed to produce aggregate which is then screened into the sizes required for immediate use or for further processing such .

Get Price -

AP42 Section Crushed Stone Processing and Pulverized .

with the diameter of the rock. The suppressive effect of the moisture depends on both the absolute mass water content and the size of the rock product. Typically, wet material contains > percent water. A variety of material, equipment, and operating factors can influence emissions from crushing. These factors include (1) stone type, (2) feed ...

Get Price -

Crushing It: Improving cone crusher performance through ...

· This allows operators to maximize the life of wear components – while preventing costly damage and unplanned downtime due to component failure. Ensure reliable, safe performance. An automated alert is integral in detecting potential bowl float. Also referred to as "ring bounce" or upper frame movement, bowl float occurs when crushing ...

Get Price -

Crushing and Screening Handbook

standard in the crushing industry. Rock quality, feed grading and selected machines are entered to simulate the expected production capacities and product gradings. Contact more informa tion. Complete stationary or mobile plants Besides off ering complete stationary installations, is the pioneer in fully mobile inpit .

Get Price -

flowchart of processing rock crushing unit

Comprehensive Industry Document Stone Crushers Central . the State Pollution Control Boards the Stone Crushing Units and their Association during the Study is Schematic diagram of wet dust suppression content in the rock type of rock processed type .

Get Price -

Crushing – Baioni Crushing Plants

ABLE TO CRUSH VARIOUS MATERIALS PRESENT IN NATURE ACCORDING TO THE GRANULOMETRY THAT YOU WANT TO OBTAIN, DIFFERENT STAGES OF CRUSHING CAN BE FOLLOWED: PRIMARY, SECONDARY, TERTIARY. STURDY AND RELIABLE MACHINES 1st stage feeding prescreening 2nd stage crushing 3rd stage screening sizing 4th stage .

Get Price -

700tph Iron Ore Crushing Plant

· According to the traditional iron ore processing process, the jaw crusher is used for rough crushing, and the ore is subjected to primary rolling from large pieces to small pieces. The counterattack crusher performs the second crushing, and finally the cone crusher controls the size of the ore particles. Minimize the loss of the crusher.

Get Price -

A review of modeling and control strategies for cone crushers .

· Comminution is an important unit operation of the mineral processing chain that involves rock blasting and mechanical comminution (crushing and grinding). The goal is to liberate the minerals of interest from raw ore so that subsequent concentration processes can operate optimally ( Hodouin et al., 2001 ). Quarrying industry

Get Price -

rock crushing plant flowchart

Aggregates Crushing Plant Process Flowchart Crusher flow chart of rock crushing plant rkpackersin. Process Flow Diagram for Rock Crusher Quarry crushing plants aggregate and mining Quarry crushing plants flow chart SAMAC carries out the star level service and valuable service along with the full process flow chart of the production process in a crushing plant .

Get Price