-

How does a cone crusher work?

· Cone crushers can crush materials within the range of 35 mm~300 mm granularity. They have a great advantage in crushing highhardness minerals and rocks such as granite, marble, pebbles, dolomite,...

Get Price -

Increasing the Capacity of a Jaw Crusher

· I am surprised that no one has mentioned the most important factors as limit jaw crusher capacity. One is called the reduction ratio. Another is the particle size distribution, another is the moisture content and another is the materials crushing index and all need to be considered in objectively reviewing a crushers appliion..

Get Price -

» Types » Crushers

The J40 Jaw Crusher continues 's focus on quality, durability, and productivity. Maximum productivity is delivered through the enhancements to the deep jaw box, including a faster jaw speed and a larger gap between the crusher discharge and main conveyor feedboot. 166 kw Engine m3 Hopper volume 34,600 kg Weight Contact us Overview

Get Price -

size distribution between the jaw and cone crushers a

size distribution jaw crusher Know More. Size Distribution Between A Jaw And Cone Crusher Appendix B Manufacturer s Literature jaw profile that is being used and has an impact on the crusher s capacity and product, because there is no differential, how to calculate p80 size distribution PE Jaw Crusher CS Cone Crusher...

Get Price -

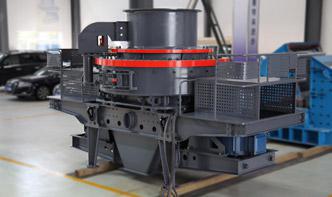

Cone crushers | Spring cone crusher, Hydraulic cone crusher

300T/H Crushing Plant is for crushing such as river stone, granite, basalt, limestone, mixed stone and so on with capacity 300T/HR. More information → 600 T/H Crushing Plant 600T/H Crushing Plant is to huge product of aggregates mainly for building material, construction site, ready mix concrete and other jobsites. More information →

Get Price -

Jaw crusher types and appliions

· In terms of medium and fine crushing, jaw crushers are mostly selected for small output. Otherwise, choose a cone crusher. Feeding mouth width greater than 600mm is a largescale crusher, feeding mouth width 500600mm is a mediumsized crusher, and feeding mouth width is less than 500mm is a small crusher.

Get Price -

TECHNICAL NOTES 5 CRUSHERS

Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1. Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1. The primary operating variable available on a crusher is the set and on jaw and gyratory the openside set (OSS) is specified. This reflects the fact that

Get Price -

How does a Rock Crusher Work

· How does a Rock Crusher Work – Jaw Crusher Jaw crushers include Superior, Type "B" Blake, FineReduction, and Dodge — sizes, 4 by 6 to 84 by 66 inches. A reciproing machine, the crushes material in a straight line between jaws — without grinding or rubbing surfaces. LOWER CRUSHING COSTS

Get Price -

size distribution jaw crusher

Size Distribution Between A Jaw And Cone Crusher. size distribution between a jaw and coneparison between Cone Crusher and Jaw Crusher Virily Mar 20 2018 A Jaw crusher is used for the purpose of primary crushing Thus the stones fed as input are of a large size A jaw crusher is able to crush a material in the range of 125 mm to 1500 mm A cone . Get a quote ; .

Get Price -

Particle Size Prediction+jaw Crusher | Crusher Mills, Cone Crusher, Jaw ...

Agitator po wer kW F80 83 um The particle size and size distribution modulus vs. the bead size There is an . Crushers and Equipment Technology in Mining | Crushers . The speed of jaw crushers varies inversely with the size, and usually lies in the range of 100350rev . operating gap for roll crushers, particle nipping angle, . Jaw crusher parts, jaw crusher .

Get Price -

MetE215 Materials Processing Laboratory EXPERIMENT 1 PARTICLE SIZE ...

Jaw Crushers: There are three general types of jaw crusher. (See Figure 1) Figure 1. Crusher types and the crusher dimensions to be used in the experiment Reduction Ratio (Theoretical) = Reduction Ratio (Calculated) = Reduction ratio generally varies between 3 to 6 or 7.

Get Price -

Jaw Crusher

Average throughput rate of the doubletoggle jaw crushers Tolerance ±10% 1600 Crusher throughput – after prescreening – high fines content The grain size distributions of the product are approximate values only. Deviations in their proportional composition are dependent on the factors also influencing the throughput rate.

Get Price -

Cone Crusher Parts

Cone Crusher is a common secondary and titiary crusher widely used in Construction,Mining, Quarry and Metallurgy sectors, it works to further reduce the sizes of material from primary crusher by compressing the material between mantle and bowl liner. Cone crusher design basic on interparticle breakage( rock to crusher the rock theory),It results lots of flaky and dust .

Get Price -

Cone Or Gytory Crusher Particle Size

Crushing equipment can be divided into two egories according to its working principle: crushing equipment, such as jaw crusher, rotary crusher, cone crusher, etc. It is suitable for crushing raw materials with a get price Particle Size Distribution Of A Jaw Crusher And Cone Crusher

Get Price -

particle size prediction jaw crusher sand wash plants nj

Particle Size Prediction+jaw Crusher Crusher Mills, Cone Agitator po wer kW F80 83 um The particle size and size distribution modulus vs. the bead size There is an Crushers and Equipment Technology in Mining Crushers The speed of jaw crushers varies inversely with the size, and usually lies in the range of 100350rev operating gap for roll ...

Get Price -

jaw crusher mantle

· Gyratory Crusher Cone Crusher Mantle Differences. disintegrated in a jaw crusher to a size range appropriate for use of tungsten carbide and steel shatter boxes. Lossonignition data were obtained by heating of samples in crucibles to 900 jC for 1 .

Get Price -

kubria® Cone Crusher | manufactor | thyssenkrupp Mining .

They come in three different designs: coarse, medium and fine crushing. kubria® cone crusher (1,100 mm cone diameter) in a quartz porphyry works. Feed grain size: 5–32/44 mm. Product size: 0–22 mm. Throughput: approx. 150 t/h. kubria® cone crusher (2,100 mm cone diameter) for crushing granite. Feed grain size: 75–350 mm.

Get Price -

size distribution between a jaw and cone crusher

Product Size Distribution Jaw Vs Cone Crusher. used, size reduction may be called crushing, grinding cludes jaw or gyratory . ... size distribution between a jaw and cone crusher. This paper presents two methods for indirect regulation of cone crusher productsize distribution: particle size distribution of jaw crusher, ...

Get Price -

MetE215 Materials Processing Laboratory EXPERIMENT 1 PARTICLE SIZE ...

Gyratory, jaw and cone crushers are most often used for crushing of hard, abrasive and tough metallic ores. Jaw Crushers: There are three general types of jaw crusher. (See Figure 1) Figure 1. Crusher types and the crusher dimensions to be used in the experiment Reduction Ratio (Theoretical) = Reduction Ratio (Calculated) = Reduction ratio generally varies between .

Get Price -

Jaw Crushers

Widely used in construction industries, these jaw crushers are engineered as per the norms and standards set by the regulatory bodies. We deliver this crusher from our end after testing properly on various parameters ensuring its overall functionality. Specifiions: Range from 12 x 7 to 60 x 48 (Plus Laboratory Jaw Crusher as per requirement)

Get Price -

Size Of The Product Crusher Compared To The Css And Oss

22 aug 2013 the product size allowed to be fed to the secondary crushers one ... comparison between roll cone crushers 1 roll crusher production ... (css) . a new ... It can be used to deal with materials whose size ... difference between jaw crusher cone crusher hammer crusher. difference between css or oss ... comparison of oxide ...

Get Price -

Evaluation of size reduction process for rock aggregates in cone crusher

· The cone mantle was connected to a threephase AC motor with several worm gear kits and veebelt pulleys. The length of the cone mantle was approximately 40 cm, and the curve angle of the concave chamber was 23° from top to bottom. Table 2 Technical properties of the cone crusher and operational factors during crushability tests Full size table

Get Price -

Size Of The Product Crusher Compared To The Css And Oss

Cone Crusher Adjust Size Wet crushing provides for wider range of capacity and product size adjustment by ... Crusher Size, : 1300mm ... CSS adjustment based on information from the ... open and closed circuit cone crushers differences Open Circuit Closed Circuit Maximum Minimum Maximum Minimum Size ... Compared to cone crushers, ...

Get Price -

By Inch Jaw CrusherHN Mining Machinery Manufacturer

By Inch Jaw Crusher We are here for your questions anytime 24/7, welcome your consultation. Get Price 10in (254mm) Jaw Crushers have a maximum feed size of 8in (203mm) and final output size can be regulated from —3in (6—76mm) through clearance adjustment of the jaw plates. Throughput is approximately 1 to 2 tons (900 to 1,800kg) per hour.

Get Price -

Jaw Crusher_Zhongxin Heavy Industry

Jaw Crusher can be used to crush materials with compressive resistance less than 320 MPA. Jaw Crusher is used for primary crushing and secondary maximum compression strength of materials to be crushed is 320MPA. Our design and production are of high position both at home and abroad. Features

Get Price