-

Control systems introduced for coal mining conveyor appliions

· For more information on Rockwell Automation drive systems for coal mining appliions please contact the Rockwell Automation Response Center, 10701 Hampshire Avenue South, Bloomington, Minn., 55438, (800), Ext. 1439. SOURCE: Rockwell Automation Do you have experience and expertise with the topics mentioned in this content?

Get Price -

Siemens Installs Worlds Fastest Conveyor Belt and Latest .

· OLC2 is a straight conveyor operating at the speed of meters per second. Advertisement The conveyors transport the coal from the plant to the port stockpile. Both conveyors transport coal over a total distance of 25 kilometers, but its latest technology requires less energy to operate. As a result, it has less carbon emissions.

Get Price -

Optimal scheduling method for belt conveyor system in coal .

· In recent years, the belt conveyor (BC) has become the most common equipment for coal transporting all over the world, and its energy consumption is second only to the mining system. At present, most of the BCs usually run at a fixed belt speed.

Get Price -

Coal Belt Conveyor Speed

Belt Conveyors for Bulk Materials Calculations by CEMA 5. Example: Belt Conveyor Parameters Coal, anthracite, sized Capacity: 1000 tph Length: 1000 m 3300 feet Selected belt speed may require revision Coal, anthracite, sized 27 Coal, anthracite, sized 5560 1 lb = kg 1 ft3 3= m.

Get Price -

(PDF) Study of Energy Consumption of a Bucket Conveyor in a Jig ...

· Experimental studies, carried out at the "Sośnica" Coal Mine working facility, confirmed that the use of a predictive algorithm for controlling the bucket conveyor speed and adapting the bucket...

Get Price -

coal conveyor belt speeds

What Is a Coal Conveyor Belt? (with pictures) · Workers can adjust the level of incline on a coal conveyor belt, as well as the speed, to control the amount of coal delivered. Full stoppage of a working conveyor is typically rare, as such systems are often designed to operate around the clock with shifts of workers who move in and ...

Get Price -

DataDriven Cooperative Control Model of ShearerScraper Conveyor .

This paper proposes to establish a cooperative speed control rule database for coal shearers and scraper conveyors based on the rough set theory. Even if there are some incomplete or inconsistent data in the original data set, the model can reveal more useful information from the original data, thereby, obtaining the optimal decision rule set.

Get Price -

Research on Control System of Belt Conveyor in Coal Mine

· Liu X (2000) Developing trend of long belt conveyor and its control driving system. Coal Mine Mach 5(11):1–2. MATH Google Scholar Jiang W, Han D (2008) Development situation and tendency of native mining belt conveyor. Colliery Mech Electr Technol 11(1):1–6. MathSciNet Google Scholar

Get Price -

ANALYSIS OF CONVEYOR DRIVE POWER REQUIREMENTS IN TH E MINING .

Since mining activities are merely associated with bulk materials handling, conveyor drive turns out to be a widely accepted solution for the miner of the world from the 1800's [8,26]. Initially, the idea of conveyor was for the coal mining industry but now being used for all kinds of the mining industry and in modern manufacturing lines

Get Price -

SELECTION AND MAINTENANCE OF CONVEYOR BELTS

belting for transportation of coal in mines are discussed in detail. The correct designing of belts together with careful installation and maintenance of conveyors are stressed. Model techniques of selecting proper belting under the specified conditions and of estimating costs of owning

Get Price -

Variablespeed drives for beltconveyor systems

some of the benefits of controlled drives are • an optimum loading of the belts through controlling the belt speed, depending on the load volume, in the range of m/s; reference values are supplied by a laser scanner monitoring the belt load • a reduction of gear and belt wear through smooth starting and stopping of conveyors • the .

Get Price -

Types of Coal Mining

Whether it is underground mining, or surface mining, the use of quality conveyors in the coal industry is imperative to maintaining efficiency. FEECO has been involved with the coal industry for decades, providing superior quality conveyor systems, bucket elevators, belt trippers, and belt plows. Sources: (1) World Coal Association (2) Wikipedia

Get Price -

Maintaining conveyor power processes

· These main transfer conveyor systems comprise multiple separate conveyors, each with a beltwidth of two metres and a travel speed of meters per second (approximately 19 kilometres per hour), and have a combined length of 25 kilometres. The conveyors then move the coal to a raw coal bunker, which has an 80,000 tonne capacity.

Get Price -

Conveyor Belt Systems in Mining Industry

The use of conveyor belts in mining facilities causes the products of the KBT brand to be needed at many points. KBT has the capacity to produce special products according to the needs of companies. KBT Atex Conveyor Belt Safety Equipment offers products in accordance with the standards of "II 2G Ex db IIC T6, T5 Gb / II 2D Ex tb IIIC T80 ° C ...

Get Price -

Construction and Maintenance of Belt Conveyors for Coal and .

conveyors for coal and bulk materials is given in the following chapters. 4 ... have lesser belt speed whereas less abrasive material can be conveyed at higher speed. The agitated condition of material on a belt also causes wear on the belt surface continuously from loading point to discharge point. Conveyor Capacity Belt conveyor is required to convey certain quantity of .

Get Price -

Variablespeed drives for beltconveyor systems

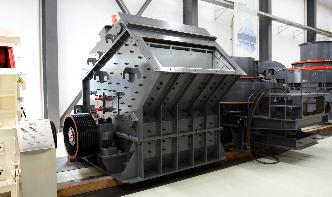

Fig. 1: View of a coal conveyor This is the description of such a drive concept covering five belt conveyors implemented recently by ABB. For the first time ABB Automation has used here grid converters according to the latest developments of drive technology. Fig. 2: Beltconveyor scheme 1 2 3 U Drive U U Drive D r i v e U 44 U U U U U Drive U 1552 m 1482 mDrive U 906 .

Get Price -

ANALYSIS OF CONVEYOR DRIVE POWER REQUIREMENTS IN TH E MINING .

This was found to be primarily the result of the maximum tonnage of the two adequately powered conveyors being 1500 tonnes per hour (TPH) while the inadequately powered conveyor was classed with a maximum tonnage of 1800 TPH. It is recommended that the current draw for each motor when fully loaded be measured. This will be compared to the design.

Get Price -

speed of conveyors in coal mining

Conveyors in Mining International Mining 1/10/2012 Some 40 years ago, the strongest conveyor belt was an St 4000, used in an underground coal mine in Europe (St 4000, the rating as per DIN 22131, stands for a minimum breaking strength of 4,000 N/mm of belt width) A Phoenocord St 5400 was supplied for the German hard coal mining group R, 15 years later

Get Price