-

Steelslag: a supplementary cementious material and basis for energy ...

· Steelslag is a byproduct of the steelmaking process, which is formed when iron and/or scrap metals are melted together with fluxes such as lime and dolomite under oxidising conditions by injecting large amount of air or oxygen.

Get Price -

Steel slag in China: Treatment, recycling, and management

Steel slag is the main waste product in the steelmaking process. Because of its chemical composition and technical properties, it can be reused as raw material in steel plants and can serve as a substitute for aggregates in civil engineering. In this paper, we reviewed steel slag treatment, recycling, and management in China.

Get Price -

JSW

following extensive theoretical studies, laboratory testing and field studies, jsw steel has developed an innovative process for transforming waste steel slag into is383:2016 code for aggregates for concrete, compliant sand that is suitable for construction, as well as slag fines which can be used in cement making as well as some agricultural .

Get Price -

Steel slag pretreatment process

· The steel slag processing mainly uses water as a medium for cooling treatment on the steel slag, through physical cooling to achieve the separation of materials containing iron and calcium silie in steel slag, so that crushing and magnetic separation can be conducted to effectively facilitate the separation of the two kinds of material.

Get Price -

Assessment of Electric Arc Furnace (EAF) Steel Slag Waste's

Steel slag is one of the most common waste products from the steelmaking industry. Conventional methods of slag disposal can cause negative impacts on humans and the environment. In this paper, the process of steel and steel slag production, physical and chemical properties, and potential options of slag recycling were reviewed. Since steel is mainly .

Get Price -

86 IRON AND STEEL SLAG

Slag was processed by 28 companies servicing active iron and steel facilities or reprocessing old slag piles at about 129 processing plants (including some iron and steel plants with more than one slagprocessing facility) in 33 States, including facilities that import and grind unground slag to sell as ground granulated blast furnace slag (GGBFS).

Get Price -

Technical Report UDC 669 . 184 . 28 Development of Steamaging Process .

Figure 1 shows a result of an experiment about how the amount of expansion (hereafter called as expansion stability ratio) of steel slag changes in the case of steel slag crushed to below 25 mm in size being held for a certain dura tion under the steamy atmosphere at the ambient temperature of 50°C, 75°C and 100°C.

Get Price -

Types of iron and steel slag : NIPPON SLAG ASSOCIATION

Steelmaking slag This slag is a byproduct from steelmaking processes in which the components of pig iron and steelscrap are modified in order to produce steel that is so highly valued for excellent toughness and workability.

Get Price -

Iron and Steel Production | Eippcb

This BREF covers the processes involved in the production of iron and steel in an integrated works as well as the production of steel in electric arc furnace steelworks. The main operations covered are: • loading, unloading and handling of bulk raw materials • blending and mixing of raw materials • coke production

Get Price -

Preparation and performance characterization of steel slagbased ...

2 days ago · Therefore, new technologies must be used to deal with steel slag. In this study, the steel slag powder refined by the wet grinding technology is used as the matrix material, MgO as material...

Get Price -

products of slag processing plant

Steel slag i ntroduction:. The steel slag crushing production line is a production line for recycling and recycling of steel slag and other resources based on the characteristics of steel slag hardness and rationally equipped provides customers with technical services and design of 30 800tph steel slag processing line! Get a quote

Get Price -

Metal Processing

Metal Processing The selection of vehicles from KAMAG Transporttechnik for the metallurgy industry is as wide as the range of transport assignments in this sector. Scrap management, molten steel, slag or slab and semifinished materials transport: wherever a transportation task presents itself, KAMAG will deliver the best solution.

Get Price -

(PDF) Steel Slag as A Road Construction Material

· Even the composition of steel slag coming from same plant may vary due to variation in dosage of ingredients, process used and grades of steel produced in the plant [2,13, 51, 60].

Get Price -

Electroslag Remelting Process – IspatGuru

· The ESR process is based on an electrical current running through an electrode through the liquid slag and ingot. Due to the high electrical resistance of the slag, the slag heats up and melts. The complete remelting process is carried out in a watercooled copper mould, which allows the remelted ingot to solidify quickly and very uniformly.

Get Price -

Slag processing

Slag processing and recovery of industrial waste. From special waste to resource: the recovery of industrial waste, ... If steel mill slag was considered special waste up to a few years ago, today this industrial byproduct is a valid source of recovery of metal and nonmetal material.

Get Price -

Mechanism of Acid Mine Drainage Remediation with Steel Slag: A .

· The adsorption mechanism of steel slag can be divided into physisorption and chemisorptions. Physisorption mainly relies on the van der Waals force between steel slag and pollutants. Chemisorption involves the transfer of electrons between the adsorbate and adsorbent and the formation and destruction of chemical bonds.

Get Price -

Preparation and performance characterization of steel slagbased ...

2 days ago · This paper details the development process of ceramics made out of electric arc furnace (EAF) steel slag, to be used as a shaped homogenous thermal energy storage (TES) media in packedbed ...

Get Price -

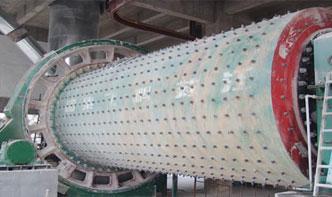

The Equipment of Steel Slag Processing

Luoyang Dahua developed dry process and wet process techniques for steel slag recycling. No water is required in dry process of steel slag production, the slag would be crushed, milled and magnetic processed and then changed into grade A or B waste steel, the iron content could be over 55% and the content of magnetic iron in 510mm tailing slag is below 2%.

Get Price -

Chemical characteristics of iron and steel slag : NIPPON SLAG .

The shape and physical characteristics of iron and steel slag are similar to ordinary crushed stone and sand, however due to differences such as the chemical components and cooling processes, it is possible to provide different types of slag with a wide variety of unique properties.

Get Price -

Detailed Treatment Process of Steel Slag

· 1. Steel particles, iron powder and waste ash are formed by high temperature in the smelting process. In order to effectively separate the steel particles and iron powder, the steel slag is first to be ground to break the structure between the three and make them separate. The best equipment for grinding steel slag is a ball mill.

Get Price -

AMCOM LLC

Turnkey, equipment leasing Metallurgical byproducts processing AMCOM is an international company, which offers custom made solutions for processing metallurgical slag and scrap, enrichment of iron ore, and other equipment for the steel and coal industries. Since 2000 AMCOM designed and launched eighteen processing plants.

Get Price -

Stainless Steel Slag Fundamentals – From Furnace to Tundish .

Stainless Steel Slag Fundamentals – From Furnace to Tundish Eugene B. Pretorius and Robert C. Nunnington Process Technology Group Baker Refractories 232 E. Market St York, PA, USA Key Words: Slag, viscosity, saturation, solution, stainless steel, decarburization, reduction, inclusions, tundish, ladle, flux Abstract

Get Price