-

Tower Mill Liners

Tower Mill Liners ME Elecmetal Product / Grinding Tower Mill Liners ME Elecmetal provides topquality, highly engineered spiral / impeller liners for stirred media mills. Our tower mill liner products are used by some of the biggest names in the mining industry and are manufactured with the optimal blend of wearresistant alloys.

Get Price -

tower mills grinding

Swiss Tower Mills Grinding tower mill fine grinding khomananicollegeultra fine grinding tower mill Crusher Manufacturer High Intensity Grinding Mill Handles Fine and Ultra Fine Sep 27 2013 Swiss Tower Mills Minerals Ltd is an . Size Reduction Visual Encyclopedia of Chemical Engineering. Size reduction in attrition mills occurs The most commonly used attrition mills .

Get Price -

tower mills grinding

Mill grinding Source http en wikipedia org wiki Mill grinding Updated In tower mills there is no cascading action as in standard grinding mills . Tower Grinding Mill Works Shanghai . Tower Grinding Mills for sale – Heavy Industry Tower Grinding Mills for sale Tower mills low speed vertical stirred mills and high speed stirred mills . TECHNOLOGY SELECTION OF STIRRED .

Get Price -

Tower mill, Willaston

Item. 2 March 1937. Part of SPAB Mills Section Collection. Handwritten note on reverse reads " Received from: J. Chettleburgh, 7 Kenwyn Drive, Cricklewood. Willaston Mill, Wirral, Cheshire. A fund is being raised to repair and preserve this mill as a landmark." Chettleburgh, John, photographer.

Get Price -

Whats a tower mill? Explained by FAQ Blog

· A windmill is a structure that converts wind power into rotational energy by means of vanes called sails or blades, specifically to mill grain (gristmills), but the term is also extended to windpumps, wind turbines and other appliions. The term wind engine is sometimes used to describe such devices.

Get Price -

Vertical Media Mill To Grind Paint

Mill structure The vertical stirred media grinding mill uses a grinding chamber filled with small beads whereby comminution takes place by attrition between the beads. The stirring effect is caused by rotating discs mounted on a shaft. There are also stationary discs on the mill body positioned in Get Price

Get Price -

Is media shape important for grinding performance in stirred mills ...

· The tower mill employs a double helical, steel screw agitator inside a cylindrical grinding chamber. The pilotscale tower mill used in this study is shown in Fig. 1 with dimensions summarised in Table 1. The screw stirs the media while simultaneously lifting and circulating it throughout the mill.

Get Price -

Tower mill and its appliion to fine grinding

andchief engineer (formerly) Tower mills crushers, respectively, Mineral Processing Systems, lnc., York, PA. ( Stief and Wilson are currently employed elsewhere.) SME preprint 84125, SME·AIME Annual Meeting, Los Angeles, CA, February 1984. Manuscript January 1984. Discussion of this paper must be submitted, in duplie, prior to April 30, 1987 FEBRUARY .

Get Price -

tower mill for grinding ball mill

Ball Mill is a D x L Tower Mill is a D x L 520KW Table 2 Mill Comparison of Media Size, Power Intensity, number of grinding media The ability to use smaller media is probably the dominant impact on grinding efficiency. It dramatically increases the grinding surface area and the number of grinding events, essential to efficiently grind fine .

Get Price -

Tower Grinding Mills

Tower T80400 Electric Salt And Pepper Mills Grinder Set. Buy Tower T80400 Electric Salt and Pepper Mills Grinder Set in Black Brand New from only 2368 Add seasoning to soups salads and other meals at the touch of a button with this stylish salt and pepper mill set Suitable for all types of herbs and spices these mills will efficiently grind peppercorns rock salt and other common .

Get Price -

vertical tower grinding mills

· The Tower mill is a vertical stirred grinding mill which can be used in both dry and wet grinding appliions. It has provided a means of size reduction in an area where conventional tumbling mills become inefficient (Morrell et al, 1993). The major advantage of the Tower mills over the ball mills in

Get Price -

tower mill tower grinding mills tower mills

201663 · The Tower mill is a vertical stirred grinding mill which can be used in both dry and wet grinding appliions. It has provided a means of size reduction in an area where conventional tumbling mills become inefficient (Morrell et al, 1993). The major advantage of the Tower mills over the ball mills in

Get Price -

tower mill for grinding

Mpsi Vtm500 Vertimill/tower Mill. Categories: GRINDING EQUIPMENT. SubCategory: VERTICAL MILLS. Loion: Manufacturer: MPSIHARDINGE. Model : VTM500/ kW 500 Tower Mill. Manufacturer : MPSI. HP or KW : Brief Description . MPSI VTM500 Vertimill/Tower Mill. Attachments 6CEE02Falk Outline 6CEE02Falk Product . Get .

Get Price -

Mill (grinding)

SAG mills use a ball charge of 8 to 21%. The largest SAG mill is 42' () in diameter, powered by a 28 MW (38,000 HP) motor. A SAG mill with a 44' () diameter and a power of 35 MW (47,000 HP) has been designed. Attrition between grinding balls and ore particles causes grinding of finer particles.

Get Price -

What Are Mills Used For?

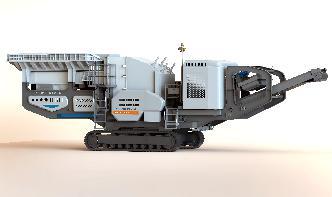

· Tower Mill Tower mills are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills in a grinding process. Grinding (steel) balls or pebbles are often...

Get Price -

ISAMILL FINE GRINDING TECHNOLOGY AND ITS ...

problems of overgrinding the galenabearing minerals as the cyclones returned the smaller but heavier galena particles and coarser but lighter gangue particles to the underflow for further grinding. The effect of this phenomenon is illustrated in Figure 5. Figure 4: ClosedCircuit Tower Mill for Treating Bulk Lead/Zinc Concentrate 70 50

Get Price -

FL installs world's largest vertical steelmedia tower mill for ...

· This FTM4500 installation expands FL's tower mill references into North America, well beyond several proven installations in Asia, where 500hp and 1,500hp mills are in operation. Standard FTM sizes include the 1000hp, 3500hp, and soon a 6,700hp version.

Get Price -

HIGmillTM mill for regrind project

The HIGmill TM provides several unique advantages such as a low specific grinding energy (SGE) value combined with high power intensity, simple flow sheet with no recirculating loads, true flexibility in process variables and long maintenance intervals. Deliveries are scheduled for the first quarter of 2014; startup is planned for autumn 2014.

Get Price -

tower mill for grinding purposes

Tower Mill Tower Grinding Mills Tower Mills. Grinding Equipment In Tower Windmill A tower mill is a type of windmill which includes a brick or stone tower, together with which sits a roof or 12% are grinding equipment, and 12% are flour mill. A wide variety of grinding mill options are available to you, such as raymond mill, ball mill. Read More

Get Price -

Mill (grinding) | Detailed Pedia

Like ball mills, grinding (steel) balls or pebbles are often added to stirred mills to help grind ore, however these mills contain a large screw mounted vertically to lift and grind material. In tower mills, there is no cascading action as in standard grinding mills. Stirred mills are also common for mixing quicklime (CaO) into a lime slurry.

Get Price -

Stembridge Tower Mill

Stembridge Tower Mill is the only remaining thatched windmill in Great Britain and dates from the 1820's. The windmill was used to grind small amounts of grain for local people. The mill was restored in the 1970's and is now managed by the National Trust. Robert Tatchell constructed the mill in 1822 and it is now a Grade II listed building.

Get Price -

Tower Mills : Sus Mills Group

The Tower Mill, as the name suggests, is a tapered tower usually constructed of brick or stone. Many Tower Mills have stages built around the outside from which the sweeps were set or controlled. These stages are usually made of wood, but iron examples can be found. Tower Mills vary considerably in height from just 30 feet to over 130 feet tall. On top of the tower is a cap .

Get Price -

tower mill grinding

Mill (grinding) Wikipedia. Tower mill. Tower mills, often called vertical mills, stirred mills or regrind mills, are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills in a grinding . Check now. Swiss Tower Mills Minerals AG. Swiss Tower Mills Minerals AG (STM) was founded in 2012 to introduce the well proven fine .

Get Price -

Ultra Fine Grinding Mill Tower

Hch Ultrafine Grinding Mill Grinding Mills Ultrafine. HCH Ultrafine Grinding Mill is widely used to grind any nonmetallic minerals with Mohs hardness below 7 and moisture below 6, such as talc, calcite, calcium carbonate, dolomite, bentonite, kaolin, graphite, carbon black etc This kind of mill is especially suitable for ultra fine grinding ...

Get Price -

tower grinding mills

tower mill for grinding – Grinding Mill China. Variables affecting the fine grinding of minerals, Stirred mills have become the pre ferred option for regrinding and fine grinding The most commonly used stirred mills in the minerals processing industry are: Tower mill: Manufactured in Japan by It was the first low speed stirred mill.

Get Price