-

Ferric chloride | FeCl3

Ferric chloride is an orange to brownblack solid. It is slightly soluble in is noncombustible. When wet it is corrosive to aluminum and most metals. Pick up and remove spilled solid before adding is used to treat sewage, industrial waste, to purify water, as an etching agent for engraving circuit boards, and in the manufacture of other chemicals.

Get Price -

Electric Motor Thermal Management

•Motor Industry Representatives ... "Thermal Model of a Permanent Magnet Motor for a Hybrid Electric Vehicle," Department of Electric Power Engineering, Chalmers University of Technology, Göteborg, Sweden, 1999. UWMadison PM Motor with Concentrated Winding. ORNL PM Motor Benchmarking with Oil Cooling. Published PM Motor

Get Price -

Magnetic Particle Inspection Consumables | Magnaflux

Improve your magnetic particle inspection with Magnaflux fluorescent powders, visible and colored magnetic particles, carrier liquid, contrast aid paint and other products for mag particle testing. Find out more about Magnaflux's reliable and tested magnetic particle products for wetmethod and drymethod MPI and MT magnetic particle testing.

Get Price -

Water Requirements of the Iron and Steel Industry

iron industry were operated as mineconcentration plant combinations, although in some places the distance from the mine to the concentra tion plant was a few miles. Only one mine and one concentration plant operated as independent units. The steel plants include both integrated steel plants (plants that begin with concentrated iron ore

Get Price -

Iron ore

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite (Fe 3 O 4, % Fe), hematite (Fe 2 O 3, % Fe), goethite (FeO(OH), % Fe), limonite (FeO(OH)·n(H 2 O), 55% Fe) or .

Get Price -

wet magnetic concentrated industry of iron oreppt

Wet iron remover equipment introduction Know More. Iron separators are widely used in recycling, wood industry, mining, ceramics, chemicals, food and other projects The iron remover is suitable for magnetite ore below 3mm, pyrrhotite, calcined ore and ilmenite wet magnetic separation material, and is also used for iron removal materials such as coal, nonmetallic .

Get Price -

BEST AVAILABLE TECHNIQUES ON THE PRODUCTION OF IRON .

· IRON AND STEEL INDUSTRY. This BREF covers the processes involved in the production of iron and steel in integrated steelworks. Iron and steel are important products that are widely used. Slideshow by armandmcmahon. Browse . Recent Presentations Content Topics Updated Contents Featured Contents.

Get Price -

wet magnetic concentrated industry of iron ore ppt

Basics in Minerals Processing . 3 3 Crushing of ore and minerals 5 30 Technical data Wet cyclic high gradiant magnetic filter HGMF 6 62 Major process equipment components of iron ore pellet plant construction ballast metals and industrial mineral fillers Operations are Clay contamination is concentrated in well defined layers Open pit

Get Price -

Various Wet Magnetic Concentrated Industry Of Iron Ore Ppt

Froth Flotation Process Mineral Processing. The Froth Flotation Process is about taking advantage of the natural hydrophobicity of liberated well ground mineralsmetals and makingplaying on making them hydrophobic waterrepel individually to carefully separate them from one another and the slurry they are in.

Get Price -

Why Iron Rusts (And How to Prevent It) | Blog Posts

· The Science Behind Rusting. Iron, as well as iron alloys, rusts because of a chemical reaction known as oxidation. When iron is exposed to moisture or oxygen, oxidation occurs. During this chemical reaction, iron is converted into iron oxide. The iron oxide typically has a reddish, flaky appearance that becomes progressively worse over time.

Get Price -

Direct Observation of Sulfate Explosive Growth in Wet Plumes .

· Here, we first report direct observations of sulfate production in stack plumes discharged from coalfired power plants, industrial boilers, and sintering plants equipped with wet desulfurization systems. Less than one third of the particulate SO 4 2− in plumes is attributed to dustSO 4 2− and SO 3 measured in stacks.

Get Price -

search results

wet magnetic concentrated industry of iron ore Iron Ore Magnetic Separation. The largest development in the ironore industry using magnetic concentration is at the plants of Witherbee Sherman Co at Mineville N Y where about tons of crude ore were mined and separated in 1916 The dry process of separation is used The Chateangay Ore Iron Co at Lyon Mountain .

Get Price -

Iron Ore PRICE Today | Iron Ore Spot Price Chart

· Iron Ore Price: Get all information on the Price of Iron Ore including News, Charts and Realtime Quotes. Menu icon A vertical stack of three evenly spaced horizontal lines.

Get Price -

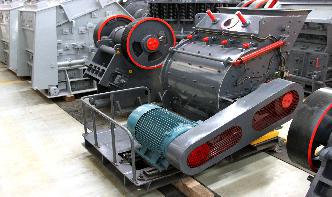

wet magnetic concentrated industry of iron ore

150tph andesite crushing and reshaping production line. Material : andesite Output size : mm Capacity : 150tph Equipment : ZSW1100X4200+PE750X1060+CSB160+VSI5X8522+3YZS2160

Get Price -

Eriez Magnetic Separation

Eriez Permanent Magnetic Separators require no electric power. With proper care, they can last a lifetime with very little loss of magnetic field strength. Eriez permanent magnets are supplied for a wide range of appliions including dry bulk materials, liquids or slurries and even high temperature appliions.

Get Price