-

Constructing gravel road on the side of a hill

· The hill base material is clay while the road goes through a forest. The road will be half cut into the hill and half back filled to give a 5 degree slope into the hill. A ditch on the hill side will drain water to one of 3 culverts which will run across the road at 50 foot spacing.

Get Price -

stone cone crusher machines

Section 3 Hydraulic cone crusher of Machinery is mainly composed of many parts, such as feeder, chute, magnetic separator, cone crusher, wheels or crawlers, etc. Hydraulic cone crusher is the host part of crusher plant and it can be freely matched with singlecylinder cone, multicylinder hydraulic cone, full hydraulic cone and spring . Get Price

Get Price -

EIS 416 AA054582 Proposed sand and gravel extraction and operation .

Plate 1 View of the processing equipment showing the primary crusher (centre right), the secondary crusher and washer (left) and the revolving screens (centre background). ir4 Plate 2 View south from the north bank showing the existing access track to the bed (foreground) and the low flow channel adjacent to the southern bank.

Get Price -

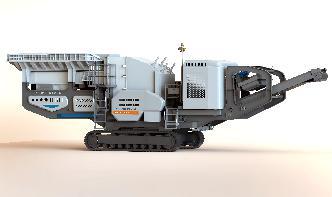

Crushing plant

Components [ edit] Crushing plants make use of a large range of equipment, such as a prescreener, loading conveyor, intake hopper, magnetic separator, crushing unit, such as jaw crushers and cone crusher etc. Vibration feeder: These machines feed the jaw and impact crusher with the rocks and stones to be crushed. [1]

Get Price -

EIS 416 AA054582 Proposed sand and gravel extraction and operation .

I Lipka Pty Ltd is proposing to reestablish a sand and gravel extraction operation in the bed of the Cudgegong River some 33 km downstream of Mudgee and to operate a crushing and screening plant on land adjacent to the river being part I Portion 3 and part Portion 123, Parish of Puggoon, County of Bligh.

Get Price -

Parts of a Hammer (With Diagram)

· This part is used to pull out the nails or to rip woods or other materials. There is a difference in the shape of the claw among different hammers. The most common shape of claw you will get is the curved claw. You can also see the rip claws and straight claws, these are also popular. Now, not every hammer has a claw.

Get Price -

Impact Crusher | Mining, Crushing, Grinding, Beneficiation

· impact crusher have three types: PF Impact Crusher, Primary Impact Crusher, Hydraulic Impact Crusher. They are widely used in building materials, cement processing, mining and chemical industries, crushing soft material, medium hardness minerals. Maximum Feed size range (the maximum anticrushing compressive strength 300Mpa, .

Get Price -

Crushing and Screening Handbook

10 Wear Parts Crushers 11 Customer Service 12 Standards and Technical Infromation ... gravel operations, you need a partner to supply competitiveness, not just equipment. ... inpit crushing operation. Integrating two or three mobile crushing plants combined with a

Get Price -

Choosing the right crusher

The crushing device consists of a fixed plate and a swing plate called jaws between which the rock is trapped and crushed. A motor and a belt transmit the movement to an eccentric shaft that drives the movable jaw by rotation. A spring returns this moving jaw to let the crushed materials gradually descend into the crusher.

Get Price -

Top Dressing Driveway

· When they are spread on the driveway, and after the first rain, all the fines are washed into the porous spaces between the coarse and makes for a very good solid driveway. I use crushed limestone, which is about 80% coarse 20% fines, and after the first rain all the fines settle in, and it sets up almost like concrete.

Get Price -

What is an Impact Crusher?

· Vertical Shaft Impactors (VSI) consist of a feed hopper, feed tube, a rotor, and either stationary anvils or rock shelves. Essentially, feed material drops through the feed tube into the rotor, which, through centrifugal force, throws the material against stationary anvils made up of composite metal alloys or rock shelves.

Get Price -

Crushers

The crushing process takes place between a fixed jaw and a moving jaw. The moving jaw dies are mounted on a pitman that has a reciproing motion. The jaw dies must be replaced regularly due to wear. Figure shows two basic types of jaw crushers: single toggle and double toggle.

Get Price -

Construction Aggregates 101: What They Are (and Why They .

· Aggregates must have predictable, uniform, and consistent materials properties. They must be dry and clean before they can be used. Aggregates are only as good as their processing. They are mined, crushed, washed, and separated. The successful outcome of each step, the processing of a good aggregate, depends on the success of the previous step.

Get Price -

Stone Crusher Quarry Business Plan [Sample Template for .

The Fee for registering the business (venture) in Nigeria –N15,000. Legal expenses for obtaining licenses and permits as well as the accounting services (software, machines and other software) – N30,000. Marketing promotion expenses for the grand opening of Joseph Ileaboya Sons Stone Quarry Company – N150,000.

Get Price -

R Crusher Wear Parts Reference Guide

This Guide has been developed to help Dealers personnel to expand their knowledge of Crusher Wear part options terminology and help relay this information to end users in a clear and logical manner. The Guide is broken down into following sections : 1. Wear Parts Overview 2. Jaw Crusher Wear Parts 3.• Cone Crusher Wear Parts 4.

Get Price -

The Nation's Top 25 Construction Aggregates Producers

· The 100 largest construction aggregates operations produced 14 percent of the production of construction aggregates. Of the 291 million short tons of construction aggregates produced by these 100...

Get Price -

6 Types of Sand Making Machine and How to Choose the Best

· The roller crusher is a crushing equipment that uses a pair of round rolls or irregular rolls rotating in opposite direction for crushing. Its feed particle size is ≤ 30mm, and the processing capacity is 5110 t/h. Applicable materials: The roller crusher can be used for medium and fine crushing of mediumhard and soft ores.

Get Price -

Operating a Car Crusher

The car is stripped of all working parts. For example, a car may have a cracked engine block, but the transmission is fine. Salvage crews pull out the working parts for resale. A huge number of parts can be resold body panels, carburetors, wheels and tires, suspension parts and entire engines can be refurbished and sold to doityourselfers. Hazardous materials are removed.

Get Price -

Size Reduction Equipment

Ball mill machinery typically includes a motor, cylinder, and crushing medium. The crushing happens in the cylinder. The objects to be crushed are put into the cylinder together with crushing media. Crushing media may be made of many objects; a few examples are steel and leadantimony alloys, also nonmetals like ceramics and flint.

Get Price -

SAND, GRAVEL, AND CRUSHED STONE ONTHEJOB TRAINING .

SAND, GRAVEL, AND CRUSHED STONE INDUSTRY PRIMARY CRUSHING OPERATION This module describes basi c job steps, potenti al hazards and acci dents, and r ecommended safe job procedures for primary crushing operations. This job is normally done by the crusher operator, but may be done by other occupations.

Get Price -

Understanding the Sand and Gravel Business

new pits are 300 feet apart. If all the test pits show sand and gravel, it is assumed that the entire area, 300 feet by 300 feet contains sand and gravel. Test pit E is excavated but no sand and gravel are found. This means the gravel deposit ends somewhere between B and E. It can be assumed the gravel material stops halfway, or in this case, 150

Get Price -

Crushing

Outotec inpit crush and convey (IPCC) solutions provide an integrated solution consisting of crushing, conveying, and stacking equipment combined with IPCC planning and life cycle services. Through the industry's strongest building blocks of team, technology and services, Outotec is able to deliver successful IPCC operations.

Get Price -

eCFR :: 49 CFR Part 393 Parts and Accessories Necessary for .

Part of the structure, fitting or attachment on a vehicle or article of cargo to which a tiedown is attached. Antilock Brake System or ABS means a portion of a service brake system that automatically controls the degree of rotational wheel slip during braking by: ( 1) Sensing the rate of angular rotation of the wheels;

Get Price -

2016 aggregate production statistics : Pit Quarry

· Substitutes: Crushed stone substitutes for road building include sand and gravel, and iron and steel slag. Substitutes for crushed stone used as construction aggregate include construction sand and gravel, iron and steel slag, sintered or expanded clay or shale, perlite and vermiculite. Construction sand and gravel

Get Price