-

What is End Milling?

Due to the unlimited selection of varying drill bits and milling ends, the milling process is capable of producing nearly anything, including, gun parts, circuit boards, jewelry and much more. Through the use of different milling techniques and tools, distinct milling processes have been established in today's milling industry.

Get Price -

Testwork: Bond ball mill work index

The Bond ball mill work index is one of the most commonly used grindability tests in mining, and is often referred to as the Bond work index . The test is a 'lockedcycle' test where ground product is removed from test cycles and replaced by fresh feed. The test much achieve a steadystate before completion. Sample Requirements

Get Price -

Design Method of Ball Mill by Sumitomo Chemical Co., Ltd.

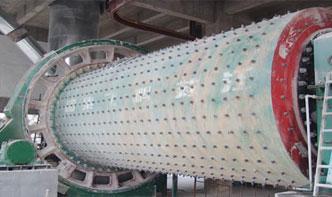

A ball mill is one kind of grinding machine, and it is a device in which media balls and solid materials (the materials to be ground) are placed in a container. The materials are ground by moving the container. Because the structure of ball mills is simple and it is easy to operate, and so they are widely used.

Get Price -

Bond Index Ball Mill / Rod Mill BT 100 XL

The Bond Index conforming rod charge consists of: 6 rods of " diameter and 21" length. 2 rods of " diameter and 21" length. The grinding jar for the Bond Index Rod Mill is 12″ x 24″ in size and has a waveshaped design. At least 15 to 20 kg sample material is required to simulate a closed grinding circuit in a ball or rod mill.

Get Price -

Pulveriser in Thermal Power Plant | Bowl Mill | Ball Mill

05/08/2021 · The Ball mill pulveriser is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter. The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for grinding, to .

Get Price -

How to install and align the girth gear and pinion | prmdrive

14/01/2020 · Their reliable operation is directly related to the stable production of the mill. In order to ensure their reliable operation, in addition to strengthening the daily maintenance and regular maintenance, the installation and alignment of the girth gear and pinion are also important. 01 installation and alignment of edge drive

Get Price -

Working Principle of Bead mill

The material is pumped into the chamber using a air operated diaphragm pump or screw pump. What happens inside Bead Mill! The necessary energy for dispersion and grinding is transmitted to the grinding beads by the agitator discs. The mill is fed continuously by the pump.

Get Price -

ball mill how does it work

Ball mill mill grinding industries scribd. how does the ball mill work cdsspgccoin ball mill slideshare introduction ball mill is an efficient tool for grinding many materials into fine of ball mill, the basic principles of the ball mill, how it works, the details of but they do not include freight, auxiliary equipment, or equipment for.

Get Price -

Ball milling: a green technology for the preparation and ...

The ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend Being an environmentallyfriendly, costeffective technique, it has found wide appliion in industry all over the world.

Get Price -

cnc ball mill diagram

Ball Mill: Operating principles, components, Uses, Jan 11, 2016· A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls mounted on a metallic frame such that it can be rotated along its longitudinal axis.

Get Price -

What is a Ball Valve? Parts, Actuation, Diagrams More

Ball valves are quarterturn on/off devices. A pivoting ball in the center of the valve controls the flow of liquid or gas media. The pivoting ball is known as a rotary ball, and it is designed with a hole (a bore) in the center. A stem on the top of the ball .

Get Price -

Ball Milling in Organic Synthesis: Solutions and Challanges

Type of ball mill: • There is no fundamental restriction to the type of ball mill used for organic synthesis (planetary ball mill, mixer ball mill, vibration ball mill, .). • The scale of reaction determines the size and the type of ball mill. • Vessels for laboratory vibration ball mills are normally restricted to a volume of 50 cm3.

Get Price -

how ball mill work

A Bond Ball Mill Work Index test is a standard test for determining the ball mill work index of a sample of ore. It was developed by Fred Bond in 1952 and modified in 1961 JKMRC CO. index is widely used in the mineral industry for comparing the resistance of different materials to ball milling for estimating the energy required for ...

Get Price -

What particle size range does ball mill grinding produce?

22/12/2016 · Ball mill grinding is one method of crushing ore to an appropriate size fraction. Specifically, ore is put into a large receptacle (a drum) and then it rotates slowly around. Inside the receptacle,...

Get Price -

Pulveriser in Thermal Power Plant | Bowl Mill | Ball Mill

05/08/2021 · The Ball mill pulveriser is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter. The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for grinding, to approximately 1/3 of the diameter. Raw coal to be ground is fed from the ...

Get Price -

Mill Levy/Rate

10/06/2020 · The mill levy/rate is a form of a property tax that is based on a property's assessed value. The mill levy's traditionally been, and continues to be, expressed in "mills.". A mill is equal to 1 for each 1,000 in assessed property value (derived from the Latin word "mil," meaning 1,000). The mill levy is calculated by determining ...

Get Price -

ball mill

26/11/2011 · Join 10,750,000 engineers with over 5,340,000 free CAD files Join the Community. The CAD files and renderings posted to this website are created, uploaded and managed by thirdparty community members. This content and associated text is in no way sponsored by or affiliated with any company, organization, or realworld good that it may purport ...

Get Price -

Using Ball Mills to Extract Raw Gold from Ores

14/06/2018 · Below is the writeup of how a ball mill works, is used to crush ore and an explanation regarding its effectiveness in gold mining. The Purpose of Milling . First of all, in order to get the best out of how this particular equipment is used it is important to get acquainted with knowledge on what it is, and is made of. Hence, a mill is a piece ...

Get Price -

Ball Milling

A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 . Types of Ball Mills

Get Price -

Introduction to Milling Tools and Their Appliion

Ball end mills produce a radius at the bottom of pockets and slots. Ball end mills are used for contour milling, shallow slotting, contour milling and pocketing appliions. Flutes Spiralshaped cutting edges are cut into the side of the end mill to provide a path for chips to escape when an end mill is down in a slot or a pocket.

Get Price -

Milling formulas and definitions

The milling process – definitions Cutting speed,v c Indies the surface speed at which the cutting edge machines the workpiece. Effective or true cutting speed, v e Indies the surface speed at the effective diameter (DC ap).This value is necessary for determining the true cutting data at the actual depth of cut (a p).This is a particularly important value when using round .

Get Price -

Milling Machine: Parts and Working

13/05/2016 · It is made by cast iron and have T slot cut over it. The work piece clamp over it by using clamping bolts. The one end of clamping bolt fix into this slot and other is fix to work piece which hold the work piece. It can provide three degree of freedom to work piece. It provides vertical motion by moving the knee up and down.

Get Price -

Milling | Ball Milling tables

The working principle of the vibratory grinding mill is based on intense motion of the grinding balls, with both inertia and centrifugal forces. The energy produced using the Sweco mill is higher than that produced by the ball mill, making it more effective in .

Get Price -

What are the Different Types of Ball Mills?

Each industrial ball mill has multiple chambers to ensure thorough grinding or mixing of materials. The added materials pass from one chamber to another to become finely ground and interlinked. Planetary Ball Mills: They are a form of vertical ball mills used for testing laboratories. They have smaller chamber balls and a limited capacity.

Get Price -

Ball mill Definition Meaning

24/05/2016 · ball mill: [noun] a pulverizing machine consisting of a rotating drum which contains pebbles or metal balls as the grinding implements.

Get Price