-

Roller Mills | Milling | Group

Automatic grinding gap adjustment. The grinding gap on our roller mills can be adjusted manually or, on some models, automatically. If you adjust the grinding gap automatically, the adjustment can be based on your recipe or on particle size. This enables you to produce a consistent and high quality of flour and semolina.

Get Price -

Vertical Roller Mill work Principle and Features

10/08/2021 · Materials with the feed tube fell to the center of vertical roller mill grinding plate, centrifugal force generated through the rotation of grinding plate uniformly sters and flattens the supplies outwards the surrounding loion of vertical roller mill grinding plate, to kinds a certain thick layer of products bed, the materials was crushed by quantity of rollers .

Get Price -

Vertical Roller Mill Working Principle

Download Vertical Roller Mill Working Principle PDF. LM Series Vertical Roller Mill Working Principle. The mill roller is driven by the electrical motor through an electrical motor and the material will be fed to the center of the disk from the feeding port via an airlocking feeder and meanwhile the hotblast air will be blown into the mill ...

Get Price -

Cement Milll Separator | Cyclone Air Separator in Cement Plant

Product Name: cement mill cyclone air separators. Capacity: 10 – 250 TPD. Condition: brand new. Airflow: 16000 – 240000 m3/h. SEND INQUIRY. Cement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plants. The function of the separator is to separate ...

Get Price -

HLM Vertical Roller Mill

The working principle of HLM Vertical Roller mill. The motor drives the reducer to rotate the millstone, the raw material are send into the center of the millstone from the air lock rotary feeder. Under the effect of centrifugal force, the material moves to the edge of the millstone. Material than be ground by the force of the roller and ...

Get Price -

INVT GD5000 MV Drive for Cement Vertical Raw Mill Heavy .

04/04/2020 · INVT GD5000 MV Drive for Cement Vertical Raw Mill Heavy Duty Load. Release time: . Click amount: 1284. Summary: In this paper, through introducing INVT GD5000 medium voltage inverter applied to vertical roller mill in the Pakistan, in order to illustrate VFD transformation of the feasibility and economy.

Get Price -

CLUM Vertical Roller Mill Working Principle, Clirik Vertical Roller ...

CLUM vertical roller mill is Shanghai Clirik technology update untrafine powder grinding mill, can be widely used in more than 300 kinds of minerals ...

Get Price -

you tube working principle of vertical roller mills nsultant

Pfeiffer MVR Roller Mills working principle Vertical mill,Vertical roller mill,Working principle of Vertical mill working principle The motor is driven by the reducer to rotate the disc The material falls from the lower feed port to the center of the disc Under the action of centrifugal force, the mill is moved to the edge of the disc and is ...

Get Price -

working of vertical raw roller mill

The working principle of vertical roller mill__csew6404. 201539 Working principle of vertical roller mill is driven by motor reducer rotating disc, and the hot air from the air inlet into the vertical mill, the material from the feed opening falls on the disc center, due to .

Get Price -

Rollerex

The Rollerex is a range of gearbox designed for the drive of vertical roller mill (cement, raw or coal). • Power from 150 to 3500 kW. • Torque from 35kNm to 1500 kNm. • Vertical static load: 1700 to 7200 kN. • Vertical dynamic load: Up to 21 000 kN.

Get Price -

What are vertical roller mill wear parts?

Answer: vertical roller mill has many wear parts. These wear parts include grinding roller, grinding millstone, classifier vane and other wear parts. This article will introduce the vertical roller mill wear parts from the function and texture of .

Get Price -

The company"s production safety accident emergency plan .

10/05/2018 · Party Building Work. Employee Activity. ... Recommended News. How to Maintain the Constant Temperature of Vertical Roller Mill. Utilization of steel slag choose vertical mill. Vertical Roller Mill in ... they believed that the plan was basically in line with the Law of the People"s Republic of China on ...

Get Price -

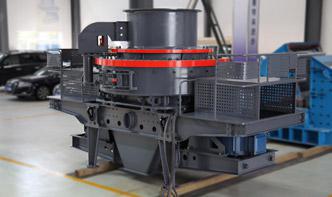

Vertical Roller Mill

Vertical roller mill (VRM) is a type of industrial equipment used to crush or grind materials into small particles. ... Jan 01, 1970 Rotary kiln working principle; Jan 01, 1970 Compact and Efficient main drive of Rotary Kilns ; Jan 01, 1970 Calcium Carbonate Rotary Kiln Manufacture; Contact; Tel +; whatsapp +; Email ...

Get Price -

Advantages and disadvantages of vertical roller mill

Vertical roller mill (vertical grinding mill) is mainly suitable for ultrafine powder processing of noninflammable and nonexplosive brittle materials with medium and low hardness and Moh's hardness of 6. The main disadvantages of vertical roller mills are: (1) Since the finished product is sent by the wind, the composition of the finished product composition is related to the .

Get Price -

Preparation works before the vertical roller mill is running

24/01/2019 · Vertical mill working principle: The material discharge pipe falls to the center of the vertical mill grinding table, and the grinding table rotates at a constant speed to uniformly disperse and flatten the raw material outward by the action of centrifugal force, so that a material bed of a certain thickness is formed, and the material is simultaneously crushed by a plurality .

Get Price -

Extension of cement works in Nigeria with two vertical roller mills .

02/01/2016 · The new cement works Silifke in the South of Turkey, approximately 100 km west of Mersin, will be equipped with stateoftheart and energy efficient Loesche vertical roller mills. ... Pakistani Kohat Cement Company Ltd. has recently ordered as many as four vertical roller mills (VRM) from Loesche in order to expand their cement plant in Kohat ...

Get Price -

Equipment : Pendulum Roller Mill | POITTEMILL FORPLEX

The POITTEMILL pendulum roller mill is a vertical mill that works by compressing the material bed. The pendulums mounted on a star wheel are driven by a vertical shaft. Each pendulum is fitted with a grinding roller that rotates upon its axis. The rotation of the star wheel combines with the articulation of the pendulum to generate a ...

Get Price