-

principles of rod mill

The main working principle of SemiAuto wire rod coil tying machine for wire rod mill is that after the billet is heated out of the furnace, the oxidized iron skin is removed by highpressure water, and then enters the fourroll reversible rough SemiAuto Wire rod coil tying machine for wire rod mill for billet processing, and finally rolled into the intermediate billet that we need and ...

Get Price -

Vertical Roller Mills

With the many advantages vertical roller mills offer, we continually develop our VRM offering with the latest upgrades, including the OKTM Mill and the ATOX® Coal Mill. The OKTM Mill skilfully comminutes raw material, cement and slag. It features a patented roller and table design and concrete mill stands instead of traditional, heavy steel ...

Get Price -

Vertical roller mill for raw Appliion p rocess materials

These days, the vertical roller mills have been widely adopted. A)Structure (1) The rollers are hydraulically pressed against a disc table and the feed is ground between the rollers and the disc table. (2) The classifier is housed above the rollers. B)Feature (1) The power consumption level for grinding is lower than that of tube (ball) mill.

Get Price -

working principal of rod mill

vibration rod mill principle wildpeppersf The working principle of mobile impact crusher ball mil,jaw crusher, vibration rod mill principle,Mobile impact crusher is a kind of crushing machinery broken material by using the impact and its widely used in mining, road, ralway, chemical industry, etc mobile impact crusher is welcomed by customers both home and .

Get Price -

Hydraulic And Mechanical Presses

The basic working principles of the hydraulic press are simple, and rely on differences in fluid pressure. Fluid is pumped into the cylinder below the piston, this causes the fluid pressure under the piston to increase. Simultaneously, fluid is pumped out of the top channel, causing the fluid pressure above the piston to decrease.

Get Price -

Grinding Machine: Definition, Parts, Working Principle, Operation ...

In brief, we can say the working of the Grinding Machine is the Workpiece is fed against the rotating abrasive wheel. The action of rubbing or friction generates between wok price and tool therefore the material removes. Lets see step by step, First, clean the machine with a clean brush. The workpiece is fixed in the worktable.

Get Price -

Hammer Mill: components, operating principles, types, uses, .

· Pharmaceutical uses of Hammer Mill. 1. It is used in pharmaceutical industries to process wet or dry granulations and disperse powder mixtures. 2. It is used in milling pharmaceutical raw materials, herbal medicine, and sugar. 3. It is used in powdering of barks, leaves, and roots of medicinal plants. 4.

Get Price -

The working principle of the ball mill_Ball mill,Lime ball mill ...

The ball mill can dry or wet all kinds of ore and other grindable materials. It is the key equipment for crushing the material after it is crushed. This article mainly introduces the working principle of the ball mill. The ball mill is mainly composed of a cylindrical barrel, an end cover, a bearing and a transmission ring gear. The barrel with ...

Get Price -

rod mill working principle

Rod Mill Working Principle Pdf Crusher For Sale Made In. mill working principleDBM Crusher · rod mill working principle pdf dccglobalschoolm. environment friendly,small occupation area, and more efficient than the traditional mill, Raymond mill is widely used in the field of metallurgy, building materials, chemical industry and mining to process .

Get Price -

Fluidized Energy Mill: Operating principles, subclasses, uses...

· VIEWS. Fluidized Energy mill, also known as micronizer or jet mill is a type of mill that consists of a hollow toroid that has a diameter of 20200 mm depending on the height of the loop which can be up to 2 m. It operates by particle impaction and attrition. A fluid or milling gas, usually air or inert gas is injected as a highpressure ...

Get Price -

VerticalAxis Wind Turbine (VAWT): Working, Types, Advantages ...

When the wind blows, it creates a positive force in the scoop and a negative force on the back side of the scoop. This difference in force pushes the turbine around. In a typical Savonius turbine, the wind comes from the front of the cylinder, causing rotation. However, wind also strikes the back of the other scoops, tending to slow the rotor.

Get Price -

What You Need to Know About Depth Micrometers

· First, you'll want to select the right rod size (which depends on the depth of the recessed area you are trying to measure). Next, clean the mounting surfaces of the measurement rod and the rodreceiving shaft. Insert and rotate the measurement rod into the rodreceiving shaft to seat it completely.

Get Price -

Rotameter Working Principle Animation

Rotameter. It belongs to a class of meters called variable area meters, which measure flow rate by allowing the crosssectional area the fluid travels through, to vary, causing a measurable effect. A rotameter consists of a tapered tube, typically made of glass with a 'float', made either of anodized aluminum or a ceramic, actually a shaped ...

Get Price -

Particle Size Reduction Mills and Sizing Equipment

To ensure that you achieve highperformance milling, you must choose the correct conical mill screen for your appliion, especially if you are working with heatsensitive materials. When milling heat sensitive products, it can be difficult to stay within the strict temperature parameters, especially for heatsensitive materials, when you have high output ambitions.

Get Price -

Working Principle Of Microhammer Mill

A Rod Mill has for Working Principle its inside filled grinding media, in this case STEEL RODS. These rods run the length of the machine. Read More Micronizer Roller Mill Working Principle Crusher Mills. Pfeiffer MVR Roller Mills working principle C ng ty TNHH Bảo Chi. raymond mill,raymond roller mill,raymond mill machine,raymond mill plant Raymond Mill .

Get Price -

Wire and Rod Drawing Process for Steel – IspatGuru

· the process characteristics of wire/rod drawing consists of (i) pulling of the wire rod/round through the die to reduce its diameter, (ii) drawing increases the length of the wire/rod as its diameter decreases, (iii) several dies are used in succession (tandem) for small diameter wire, (iv) drawn wire/rod properties gets improved due to cold .

Get Price -

working principle of rod mill

Bond Index Ball Mill / Rod Mill BT 100 XL Know More. The Bond Index Ball Mill / Rod Mill BT 100 XL is used in the planning of crushing plants, is used for particle size determination in a size range from 25 mm down to 21 mm whereas Ball Mill Work Index BWI, .

Get Price -

Ball mill

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about

Get Price -

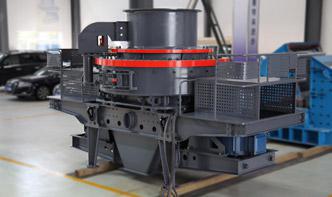

The Working Principle and Structure of Rod Mill

· This kind of main structure mainly has 15 parts: 1. 2. Main bearing department. 3. Hydraulic jacking device. 4. High and low pressure pump station. 5. Rotating part. 6. Slow device. 7. Transmission...

Get Price -

rod mill working principle

Working principle and appliion of rod mill Grinding Ball Working principle and appliion of rod mill Rod mill is made up of feeding part, discharging part, gyre part, transmission part reducer, small transmission gear, motor, and electrical controller and so on, which runs steadily and efficiently...

Get Price -

Ball Mill Machine Manufacturers Tell You the Working Principle .

· The cylinder body is equipped with the unquantified steel ball or steel rod (25mm150mm of large steel ball), which accounts for 25%50% of the effective volume of the whole cylinder body. 2. Motion state of ball mill machine. In the grinding process of the ball mill machine, the rotation speed of the barrel generally operates from high to low, which can be .

Get Price -

Appliion and Working Principle of Ceramic Ball Mill

· Compared with other ball mills, the ceramic ball mill is energysaving, timesaving and easy to operate, and its performance is more stable and reliable. Appliion of Ceramic Ball Mill. The ceramic ball mill is mainly used for mixing and grinding of materials, the fineness of the product is uniform, and the power is saved. It can be dry or ...

Get Price -

The Working Principle and Process of Roll Forming Machine

1. The working principle of the roll forming machine. Roll formers bend metal at room temperature using multiple stations where stationary rollers both guide the metal and perform the necessary bending. As the metal strip passes through the roll former, each set of rolls bends slightly more metal than the rolls in the previous station.

Get Price -

Rod Mill Working Principle

Getting started; Rod Mill Working Principle; Rod Mill Working Principle China Manufacturers, Factory, Suppliers No matter new consumer or outdated shopper, We believe in lengthy expression and trusted relationship for Rod Mill Working Principle, Impact Crusher Price, Gp200 Broken Wall, Mp1250 Cone Liner,Mp800 Cone Crusher sincerely .

Get Price -

working principle of rod mill

Rod Mill Working Principle Wikipedia Crusher India Stone. Jul 10, 2017 Working principle and appliion range of rod mill_cement . Rod mill is a kind of mill whose grinding body is steel crushing of coarse grains and selective protection of fine grains can be used as a first class opencircuit grinding widely used in artificial sand concentrator chemical plant .

Get Price