-

Innovations: Introduction to Copper: Mining Extraction

Mining of copper ores is carried out using one of two methods. Underground mining is achieved by sinking shafts to the appropriate levels and then driving horizontal tunnels, called adits, to reach the ore. Underground mining is, however, relatively expensive and is generally limited to rich ores. El Teniente, in Chile, is the world's largest ...

Get Price -

Beneficiation of Iron Ores – IspatGuru

· This process is primitive and widely used in lumpy iron ore processing to dislodge and remove friable and soft lateritic materials, fine materials and limonitic clay particles adhering to the ore. Wet scrubbing is also useful in hard and porous ores, which invariably have cavity/pores filled with clayey material that need substantial removal.

Get Price -

copper ore dressings machine

Copper ore dressing production line, After the initial separation of the magnetic separator after the mineral particles were sent to the flotation machine, .Xinhai CuPbZn Dressing Process, Dewatering Machine;, and the lead concentrate contains lead % and copper 340% A copper lead zinc ore dressing .Copper Ore Dressing, Wholesale Various High Quality Copper Ore .

Get Price -

Hindustan Copper Limited

Khetri town was founded by Raja Khet Singhji Nirwan, and Khetrinagar, which is about 10 km away from Khetri town, is developed and maintained by Hindustan Copper Limited. Mechanized underground mines namely 'Khetri' and 'Kolihan' (capacity million tonnes of ore per annum) Beneficiation plant (capacity million tonnes per annum)

Get Price -

machines required for tantulam ore dressing

Tantalum niobium ore dressing methods: 1 gravity separation method: because the valuable minerals density in the tantalum niobium ore is above 4t/m3, therefore, gravity separation is the main method of this kind of ore. For coarse grained niobium tantalum ore use jigging machine, spiral concentrator or rotating spiral roughing, coarse . Get a quote

Get Price -

Handling guide for copper concentrate in bulk

Copper wire and cable, however, account for half of the world's copper production. Hazard : No specific hazard. This cargo is noncombustible or has a low fire risk. Hold cleanliness: No special requirement. Stowage segregation: No special requirement. Weather precautions: No special requirement. Precautions : No special requirement.

Get Price -

Dressing and smelting treatment method for copper oxide cobalt ore .

Posts. PubChem ® is a registered trademark of the National Library of Medicine ® is a registered trademark of the National Library of Medicine

Get Price -

Vibrating Grizzly Feeders | Classifiion Separation | DOVE

DOVE supplies Vibrating Grizzly feeders in 34 models, with capacity range of (5 – 700 Tons/Hour), as well as special configurations for processing plants of up to 2000 Tons/Hour. DOVE standard models of Vibrating Grizzly Feeders are supplied in 11 different widths to match up to every crusher opening width. In special appliion we can ...

Get Price -

Ore processing copper ore flotation machine

According to the optimal process design scheme and combing with the basic data that customer provides, Xinhai configures the equipment in line with the principles of conducive to the production and management, ensuring the mine production safety and saving the floor, so as to provide the customers with the best solution with the maximum profits.

Get Price -

RECOVERY OF COPPER FROM OXIDE COPPER ORE BY .

The aim of this study was the recovery of copper from the oxide copper ore by froth flotation and agitating sulphuric acid (H 2 SO 4 leaching. The ore with % copper grade used in this study was obtained from ÇorumDangaz region of Turkey. Native copper, cuprite (Cu 2 O), tenorite (CuO), and malachite (Cu 2 (OH) 2 /CO 3

Get Price -

Innovative Israeli 'copper' dressing helps cure diabetic wounds

· "Copper is essential for the production of new capillaries," he added. "With our wound dressing, we are stimulating the process." Other forms of treatment currently available for diabetic wounds...

Get Price -

Quests/Blunder Hills

· Krunk is found in Freefall Caverns, the second zone of the mines, loed at the bottom of the area.. Finishing his questline will unlock a shortcut to the gold ore within Freefall Caverns, but only for characters that have completed the questline.. You must complete all three of his quests and talk to him after reaching Mining Level 25 in order to receive the Krunk .

Get Price -

Metal ore mining in Europe

Import requirements for metal ore concentrates have risen sharply in the EU. In the case of copper, imports of copper ore concentrate amounted to million tonnes per year (Mta), according to figures from Eurostat alone. Three quarters of the imports were covered by Chile (26 %), Peru (23 %), Brazil (11 %), Argentina (9 %) and Canada (6 %). For other metals, the ratios .

Get Price -

Basics of mineral processing

· 3. 3 The fundamental operations of oredressing processes are: a) the breaking apart of the associated constituents of the ore by mechanical means (severance) and b) the separation of the severed components (beneficiation) into concentrate and tailing, using mechanical or physical methods which do not effect substantial chemical changes.

Get Price -

Metal ore mining in Europe

Import requirements for metal ore concentrates have risen sharply in the EU. In the case of copper, imports of copper ore concentrate amounted to million tonnes per year (Mta), according to figures from Eurostat alone. Three quarters of the imports were covered by Chile (26 %), Peru (23 %), Brazil (11 %), Argentina (9 %) and Canada (6 %).

Get Price -

Some factors that affect beneficiation of sulphide nickel–copper ores ...

· The acceptable nickel content in the concentrate is relatively high (10–20%) and this can be achieved in many ways. One strategy is to produce copper–nickel bulk concentrate that contains about 10% of both metals. This facilitates the .

Get Price -

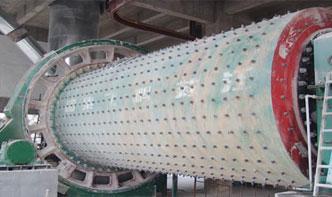

Ore Dressing Line

The materials will go into screen after first and secondary crusher, the suitable size material (≤25mm) will go to next step. Oversize (>25mm) material will go back to secondary crusher to crush again. This forms a closed crush circuit. In this process, material will be grinded into suitable sizes (about 200 mesh) for beneficiation.

Get Price -

Copper

Copper ore (chrysocolla) ... updated the estimated average requirements (EARs) and recommended dietary allowances (RDAs) for copper in 2001. If there is not sufficient information to establish EARs and RDAs, an estimate designated Adequate Intake (AI) is used instead. The AIs for copper are: 200 μg of copper for 0–6monthold males and s, and 220 μg of .

Get Price -

USA

a novel flotation promoter used in the concentration of copper bearing ores for the efficient selective flotation of copper values, including chalcopyrite, with suppression of iron pyrites; the...

Get Price -

copper ore dressing in the philippines

· copper ore dressing in the philippin 523 Economic indexes of copper ore mining and dressing industry during zones in the Philippines, Indonesia, and Papua New Guinea in southwest Pacific.... Dressing the Ore Cornish Mining World Heritage Site Know More. During the 18th century, most of the ore dressing or processing was done by hand, Copper ore was .

Get Price -

copper processing

Once a concentrate has been produced containing copper and other metals of value (such as gold and silver), the next step is to remove impurity elements. In older processes the concentrate, containing between 5 and 10 percent water, is first roasted in a cylindrical, refractorylined furnace of either the hearth or fluidizedbed type. As concentrate is fed into the roaster, it is heated by .

Get Price -

Ore dressing

· Define ore dressing. ore dressing synonyms, ore dressing pronunciation, ore dressing translation, English dictionary definition of ore dressing. n the first stage in the extraction of a metal from an ore in which as much gangue as possible is removed and the ore is prepared for smelting, refining,... Ore dressing definition of ore dressing by The Free .

Get Price -

Common Basic Formulas for Mineral Processing Calculations

· As used in these formulas the specific gravity of the ore is obtained simply by weighing a liter of mill pulp, then drying and weighing the ore. With these two weights formula (2) may be used to obtain K, and then formula (1) to convert to S, the specific gravity. A volumetric flask of one liter capacity provides the necessary accuracy.

Get Price -

Copper Ore Required

When having questions on Copper Ore Required 10000 Tons plus, please send your inquury! note_add 08/17/2016 update 08/17/2016 remove_red_eye 1019 assignmentContact Details. Please, login or get registered to contact the Author via email or personal message! ...

Get Price -

Review of copper pyrometallurgical practice: today and tomorrow

· As a guideline, the global output of copper and alloy products annually represents around tonnes of which about tonnes (75–80%) originates from refined copper while about tonnes (20–25%) is derived from directmelt scrap. Products are divided into two egories: (i) wire and cable and (ii) all other ...

Get Price